I just bought the book “Building a Shed” from Taunton press. I’m building a skid foundation just like the one on page 137 if anyone has the book. I want to build a 14 feet long 6×6 skid foundation. My problem is I can’t get pressure-treated lumber in 16 feet length. The biggest size I can get is 12 feet.

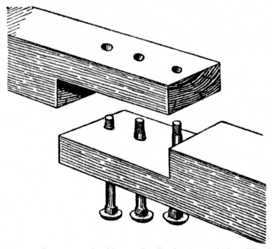

My question is should I just get two 8 foot 6×6, and cut to size, and join them together using a lapped scarf joint with Bolts like the diagram shown? And if I do use the scarf joint how long, and deep of a cut should I make to make them fit properly.

Edited 3/21/2009 5:56 pm ET by epeesolo

Replies

I'm not familiar with the article, but if you shop around I'm sure you can find 16' PT lumber. Have you just checked home centers or "real" lumber yards?

Thanks for answering my question. I thought 6x6x16 PT would be easy to find, but since I live so near to NYC there isn't much demand for that stuff. I've gone to Dyke's Lumber yard, and called several Lumber yards around the area it seems none carry that size. I would have to travel to South Jersey, or PA to get the right size. They do carry 2x6x16. I guess I could buy 3 of those bolt them together to make 6x6x16, but that's over kill. Any other suggestions?

Sure, don't build it that way.

Ok, I guess I will tell you.. That in my opinion is overkill. Why not make it with cement blocks under the 4 corners and the middle of the longest side. Then platform frame it. It is a shed, after all.

Edited 3/21/2009 8:45 pm ET by frammer52

it you go the 2x6 lamination route be sure ot find stock that is rated for ground contact. I haven't seen normally stocked 2x material that is ground contact rating (different levels of treat during the process or something like that) at the yards I use, but it can be sepcial ordered in most cases. The non-gound contact rated 2x will not last as long as the ground contact rated. The 4x stock is usually ground contact rated.

Where abouts are you? Is there a Kuiken Brothers Lumber near you?They're large enough that they might have what you need.Or maybe Excelsior in Butler?Glenn

I called up Kuiken Brothers Lumber in Midland Park, about 40 mins away. Close enough for them to deliver the 6x6x16. Thanks for the help Tashler, you made my job so much easier now. I don't know why other lumber yards around my area don't carry them?

My pleasure.Where are you located?Glenn

I live in Hoboken, NJ the birth place of Frank Sinatra. It's right across the river from NYC. It's a nice town, but parking is horiable.

Oh, I know Hoboken.I try to stay in more suburban or rural areas.Glenn

Mmmmmmmm.... Hoboken. I miss the Clam Broth House (would have loved to have the sign over the entrance before they demo'd the place) and taking the PATH to Newark and getting paella in the Little Portugal section of Iron Bound.

Steve

(formerly of NJ...but who visits often because Italian food and "bakery" bread suck in VA)

Edited 3/26/2009 1:37 pm ET by SteveVA

Great bars on Washington Street

Thanks for answering my question. I thought 6x6x16 PT would be easy to find, but since I live so near to NYC there isn't much demand for that stuff

I'm on LI 45 min to NYC and I've gotten plenty of big lumber and even timbers without ordering it in Brooklyn so check yer Yellow Pages and make some calls if you really wanna use timber sized stuff...it's there.

http://www.cliffordrenovations.com

http://www.ramdass.org

I want to build a 14 feet long 6x6 skid foundation. My problem is I can't get pressure-treated lumber in 16 feet length. The biggest size I can get is 12 feet.

@@@

Do you plan to skid it about much? The lap joint looks a bit weak - like a hinge. I'd do a long scarf joint, cutting it with a template.

However, we just ganged up 2x PT in the desired length, wider on the side that the ends, ends curved and holes for rope/chain. I can't recall any of them moving.

I built a number of 8x14 sheds for gun clubs because that footprint was too small to require a permit. You would be amazed at what you can fit in an 8x14 box. Good project for volunteers. A shed covers most of the basics of framing from roof on down.

They were all on skid kits so they could be moved as desired. The electrical connections were via a liquidtight whip from a post mounted panel. They sat on blocks.

The ToolBear

"You can't save the Earth unless you are willing to make other people sacrifice." Dogbert

How long should the lap joints be? I've read on line it should be 8x the width of the material. So, if I use 6x6 PT wood, my length should be 8x6=48. Is that right? My length of the lap is 48 inches. Is that to long?

Edited 3/22/2009 7:04 am ET by epeesolo

far better to use three full length 2xthan to create that hinge and waste a lot of material and time

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

How long should the lap joints be? I've read on line it should be 8x the width of the material. So, if I use 6x6 PT wood, my length should be 8x6=48. Is that right? My length of the lap is 48 inches. Is that to long? @@@Why use 6x6? Want to get the thing out of the splash zone as much as possible.Are you going to tow this thing about?If so, consider steel strips on the lower edges.I had diagonal bracing under mine, just in case, so it would not rack.One that was a scoring office and service center had 2x8 floor, insulated, with ply on top and OSB on bottom - make the skunks work for their new home. Results - it was a very stiff box on skids.@@@Do what Piffin suggests and laminate 2x. It will be much stiffer.You can glue, screw, nail, bolt or trunnel them together. I have no idea how construction adhesive works on PT wood, but can't hurt.What will annoy you is how the PT wood will eat the fasteners. Yes, even the fancy SST zinc ones (read their tech warning). As this is the bottom end, expect moisture. (I surveyed a deck up in the NorthWet that after 6 months had full rust on the inside of the lower post anchors and no zinc left on the thru bolt. I did not want to think about their ledger/rim connections.)To that end, bolt up the laminations in addition to nailing. Run the bolts thru PEX tubes and use BSAM under the washers - all to minimize contact between wood and metal. Less contact, less galvanic corrosion. (Bring back CCA. It worked for decades just fine.)The ToolBear

"You can't save the Earth unless you are willing to make other people sacrifice." Dogbert

There are 2 rivers in NYC. Can't you find a marine construction supply? They will have real CCA in big sizes, just swear you are using it in the salt water. (the loophole in the CCA ban).

Don't let your kids lick the skids!

Nobody uses anything as small as a 6x6 for marine construction.

Decking might be 3x6; more likely 4x6 for a commercial pier. Most structural timbers are 12x12, stringpieces are 14x14, and dolphins are whole trees with a minimum diameter of 16". Those are pile-driven, bundled in groups of 9, and strapped with 6 turns of ¾" 7x19 galvanised wire rope.

When I was still sailing tugs in NY Harbour, the preferred material was still D-fir, treated with creosote. I did see some CCA used towards the mid-80s, tho.

Dinosaur

How now, Mighty Sauron, that thou art not broughtlow by this? For thine evil pales before that whichfoolish men call Justice....

That must be a local thing. Our marine supply places in Florida have 6x6 or 6" round poles up to 2.5 CCA and go up to the 12x12 you talk about. For his purposes .8 CCA will be plenty. That is what they make stringers, posts and other above water structure out of. They still end up getting plenty wet.

Yeah, I was talking about commercial marine installations; I used to drive tugboats in NY harbour so that's what I was familiar with.

You ain't lived till you've seen 30-foot-long 14x14 timbers splinter like toothpicks and go flying thru the air 'cause some docking pilot brought a tanker in just an eighth of a knot too fast....

Dinosaur

How now, Mighty Sauron, that thou art not broughtlow by this? For thine evil pales before that whichfoolish men call Justice....

Thank you all for your insight on building the skid foundation. I've learned a lot from you professionals. As for moving the skid foundation, it's very unlikely. Once it is built, I'll be using it to store my tools and my motorcycle. I'll build it using Piffin's and toolbear's recommendations: using the three 2x6's and bolting them together using PEX tubes to protect the bolts and BSAM under the washers. I would have never thought of using pex or some kind of plastic tube to protect the bolts. Great idea toolbear.

Edited 3/23/2009 12:02 am ET by epeesolo

If you can't get poison-treated 6x6s in 16-foot lengths (which I would recommend against in any case), try to get eastern hemlock which is a naturally rot-resistant species. Given that these skid timbers are going to be in full ground contact, though, you can give them additional protection by swabbing them with a few coats of creosote.

Creosote has gotten an undeservedly bad name somehow over the years, but it is nothing more sinister than coal-tar oil. And while you certainly wouldn't want to stir any into your coffee, it is relatively benign on the surrounding environment. Prohibitions of its use on farms are limited to installations which could be chewed by livestock; it doesn't affect crops.

It also does not eat fasteners, human skin, or leech into water tables (it's an oil so it does not mix with water). Good for at least 50 years.

Dinosaur

How now, Mighty Sauron, that thou art not brought

low by this? For thine evil pales before that which

foolish men call Justice....