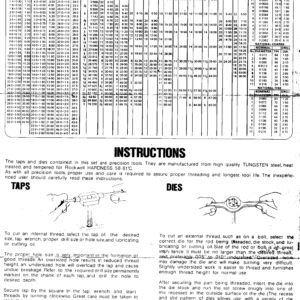

Hi, I’ve had a tap and die set that I’ve used maybe 10 times. I usually use the 1/4″ # 20 tap. I thought you drill a 1/4″ hole but it has to be smaller for it to work. The set comes with a chart. I am not quite sure how to read it. Does any one have the right hole size. Can anyone explain this chart to me?

Thanks, Ace

Replies

Use #7 drill for 1/4-20UNC tap your chart is hard to figure, there are better ones out there do a search on Google.com

What is a #7 drill?

Ace

I found a website that explains somewhat.

http://www.sheldonbrown.com/tooltips/taps.html

Ace-

#7 drill would be wire gage.

The rule of thumb that I've always used is that the tap size (hole you drill to run your tap into) should be 75% of the clear size (1/4" in this case). Therefore the tap size for 1/4" would be 3/16".

Now, I'm not a machinist, and I could be TOTALLY wrong.

Ken Hill

As a machinist, THE standard is #7 drill, though there are certain cases when you would varie the size slightly..

What's a #7 drill? It's the one between the #6 and the #8...

I think we could do something along the lines of "Who's on first?" with this one.

Cliff

Cap, your a goof!

Ace-

I went and LOOKED at the chart. This chart is for METRC, not SASE. It gives the tap drill sizes for metric, with approx. SASE equivalents, and then translates them into a bunch of other standards..........I think so, anyway.......

Aw, shucks, it's practically a guess. C'mon, let's hear from one of you SHARP whippersnappers!

Ken Hill

Here is one formula that will last you forever and is easy to remember: Tap drill size is about the screw outside diameter minus the pitch - find the closest drill size to that and you will end up with a good size. For example, 1/4-20 bolt means the outside diameter is 1/4", the pitch is 20 threads per inch, or 0.05" pitch. Subtract 0.05" (the pitch) from 0.25" (the outside diameter) and you get 0.20" tap drill size. If you have a number size drill set, you would see that a #7 drill is 0.201" diameter which is what is in the tables, and what has been posted. If you have fractional drill sizes in your set, the closest one would be 13/64", which is 0.203" diameter. If you can't find that size, go a little smaller in soft materials, a little larger in hard ones.

"Number size", or wire gage size, drills are common in machine shops and the like - they go from #1 (0.228") to 97 (a tiny 0.006"); there are also "letter size" drills if anyone mentions that - they go from A (0.231") to Z (0.413").

Hope this helps. Rich.

Edited 6/6/2002 10:48:42 PM ET by RichMast

you didnt look at all the chart Ken, first column is metric , then as you scroll to the right you will see 1/4" american standard.

Acecan, here is a link to a simple chart

http://www.shoptools.com/drillchart.htm

When doing precision work I yank out my standard drill and tap table, usually available free at stores carrying machine tool accessories and equipment, and use the fraction / number / letter bit recommended. If appropriate I grab my copy of Machineries Handbook and look up lower percentage thread equivalents. This happens about once a year.

The other 99% of the time I grab the bolt or tap and paw through my supply of bits. I hold up the bolt up to the light and hold the butt end of the bit, the end that fits in the chuck, parallel to and behind it . When you can just barely see both edges of the drill bit showing in the grooves of the threads I figure your near the industry standard 80% thread.

If you don't see the bit try a larger one. If the threads look shallow go smaller with the drill bit. In softer, or thinner, materials I might go a little smaller. In harder drill a bit bigger. Quick efficient and effective. Use a proper tap handle and drill press with a center if possible and the right lubricant.

Motto of the French Foreign Legion machinists : Tap or die.

why do all that when you can use a simple chart...LOL

Thats what we do in the USA

of course do it enuff and you don't even need the chart for the common sizes

My method is also eyeball (unless tapping tool steel or Ti) but lots coarser, esp 1/4inch and larger. Just grab any ol' bit smaller than the tap and use raw force and let the end of the tap drill ream out it's own starter hole -- talking standard taps here, not bottom or plug taps. EDM works well for removing broken taps.

My tap and die sets are in plastic cases, with the drill size chart molded into the inside of the top. That's what I go by.

-- J.S.

try looking for the package with the tap and drill with it, at home depot.

no turn left unstoned

Why do I eyeball the tap sizes? Because the box I keep my drills I use for construction has several containers with something over 250+ bits sorted into large, small, spade, masonry, etc. Many many copies of the popular sizes. Most are not marked clearly or sized. When tapping in the field I grab a handful of likely sized bits and eyeball them for fit. It might take a minute if I have to wipe my glasses. To sort them effectively I would need to spend a fortune on index boxes or be swamped by containers.

I have so many bits because lots of people think they are hard to sharpen by hand and the mechanized equivalents, the good ones, don't come cheap. On an average job I pick up at least a half dozen discarded bits of various types.

It is not uncommon that I end up supplying spare drill bits to at least one crew on a job. 3/16" jobbers length? I've got dozens of them take what you need. I still end up with more than I started with.

I don't have as many drills in the "misc" box as you do, maybe 80 - 100. But I do maintain three indexes for fractionals, and one each for number and letter. If I lose or break one from an index, I check the misc. box first for a replacement, and only buy one if I really have to.

-- J.S.