I know a lot of you place the felt and shingle over it the same day so you just shower tack it.

Others cuss about it blowing off before they can get it shingled…

Some hold it down for extended periods by tacking down scrap furring strips which have to be removed again, sometimes tearing the paper underlayment.

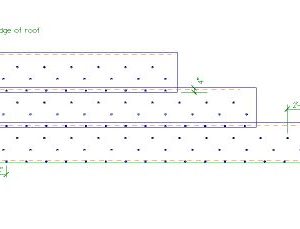

I have roofed in Texas and in the mountains of Colorado and the last fourteen years or so have been right on the Maine coast so I am confident that my method works pretty well to hold paper in place when you won’t be shingling immediately. The attachment shows a diagram of the nailing pattern I use which helps baffle the wind damage.

Note that I lap it four inches instead of two because it will shrink in the sun. I stretch it good and tight too. I use the simplex or plastic cap nails but used to use the old tintabs with staples. Either will work.

Hoping this can be a good discussion with other ideas that work well.

Replies

I don't know squat about shingling, but here's my 2 cents. Looks like a lot of nailing just for tar paper. As to the plastic caps...the ones I have seen are considerably thicker than the tin caps...does the extrra thickness cause bumps in the shingles?

The plastic caps never do show,in my experience.

As to a lot of nailing - if you use less you might get by but when you go back and re-do it three times, you've also done a heap of nailing. It really doesn't take long for someone used to fingering nails out.Excellence is its own reward!

Most roofs I've worked on don't get done in a day. So I tend to work on stuff that has the paper exposed for a heck of a long time. Two things I've done that seems to work

I've used the "scrap furring strips" you mention with quite a bit of success. But I hate pulling the nails and throwing them back off the roof.

The most creative solution I've seen is to use string along the bottom edge. Hold it up an inch or so from the bottom of the paper and staple it on every 6" or so. Keeps the edge from blowing up and tearing. And it can be shingled over without tearing it off.

"Never get into fights with ugly people, they have nothing to lose."

if i'm on the roof we do tin caps with a roofing nail gun in the pattern you show..

if i leavbe it up to someone else.. it's usually furring strips, which i've come to hate since we get more leaks for some reason...

new product we're using is a 5' roll of roofing underlayment in a 10 sq. roll.. it's a woven fabric.... like blue poly tarp... one side is coated with a sealer that seals around the nails.. and it's non-skid....

still have the first 3' with ice & water...

and it's supposed to last for 6 months wih no protection..

the roll weighs LESS than a roll of 15#felt..

and it's great for protecting tear-offs..so..( new SOP ) --- new program.. 5' underlayment with tin cps in your nailing pattern...Mike Smith Rhode Island : Design / Build / Repair / Restore

Mike -

Any brand info on the stuff you're using? Maybe a website?

Get the facts first. You can distort them later.

anyone that dries in alot of roofing should look into the cap nailer gun. Used it a few times thru the old company....really speed up the work......makes papering faster, easier and safer. Dragging a hose around was never much of a problem. The gun took a few dives.....kept right on nailing. Only pain was getting the cap strips lines up good with the nails when reloading.

One guy holding and rolling...one following behind nailing.....time flies when yer having fun. Really nice when ya have that one last section...and it's like 112deg out..and the sun just somehow got brighter!

I found the paper stays put better as the temptation is to put more nails...not less! Always followed a pattern similar to Piffins. And I've never noticed the caps telegraphing thru. Jeff She's exotic ,but not foreign, like an old Cadillac......she's a knockout!

Hey, this is going great! I like the string idea of Bosshog even if it seems time-consuming, but I really love that product Mike mentions. Now if he can just share that trade secret...Where do we get it Mike?

It isnt called Typar is it?

;>)

Long time ago, you could buy slam staplers with a magnet mounted to the front slam trigger. You could slap a tintab out of your hand and then slap it onto the roof where you wanted it. No rolling off or blowing away in the wind or sliding under your foot. I would do until you stocked the roof but the staples wouldn't hold long in a high wind unless you renailed with real nails through them but lourd they were fast!

Excellence is its own reward!

lessee... the wrapper that i cut off it says:.."Roof TopGuard Underlayment"

Classic Products Inc. Warnock Hersey

mfr'd by Rosenlew RKW Finland Ltd. made in Finland

200' x 60" wt. 32 lb.

Steve Hazlett put me onto it.. and i asked my roofing supply company to find me some... this is supposedly the 2d generation and the 3d generation will be better in the non-skid department... but i'll use this stuff just like it is.. good by to everything else for tear-offs..Mike Smith Rhode Island : Design / Build / Repair / Restore

Mike,

I was at an open house at my local roofing supply and was asking about this product based on something I had read here or elsewhere. I talked to the GAF rep and he said there are some problems with this material acting as a vapor barrier on roofs. He said that condensation will form on the underside as it is not permeable. I'm thinking the product you describe sounds good, and would like to try it but I'm not sure if the Gaf guy is poo-pooing it because they don't have it yet.

It would seem to me that Ice and water guard is definately a vapor barrier, if not felt too, contrary to others claims that felt is permeable. What are your thoughts, or what have you heard regarding this argument?Tom

the vapor barrier problem was not foremost on my list.. maybe Steve Hazlett knows more.. but the main problem was getting enough non-skid surface to it..

also.. we use soffit and ridge vents which the instructions call for .."buildings must have proper ventilation whenever a moisture barrier such as Roof TopGuard is installed"

hey, some low pitch roofs we do a complete overlay with ice & water.. how permeable is that ?..my guess... any moisture problem in a house is still a moisture problem wether or not there is an impermeable layer on the roof (SBS or rubber come to mind )Mike Smith Rhode Island : Design / Build / Repair / Restore

Mike, I sent a sample of Roof Top Gaurd and a spec sheet PLUS a sample of TRI-FLEX 30 and a spec sheet to my primary shingle manufacturer. The info that I got back was that they would not approve Roof Top Gaurd as an underlayment for several reasons---one of which was "controlled shrinkage".So I threw away about a half a roll of the stuff I had on hand( I found it incredibly slippery with even the slightest moisture on it anyhow)

The TRI FLEX30 was approved(http://www.flexia.ca)

You may want to check with your primary shingle manufacturer( Certainteed ain't it? ) to make sure they will allow Roof Top Gaurd

steve: the "controlled shrinkage" you referred to.. does that mean it gets tighter after it is installed ?.. i noticed that.. they also said the next generation would improve on this one.. i'll ask my rep. to look into the Flexia-30 too..

the non-skid was about the same as 15# felt with us...the one thing about footing confidence was that this stuff doesn't tear out when the guys with heavy feet step on it like the felts like to do on super hot days

thanksMike Smith Rhode Island : Design / Build / Repair / Restore

Yeah,

Steve mentioned the other thing that scared me off. The gaf guy said it wasn't approved underlayment for their shingle warranty.

There was a good article in this years Houses issue that talked about the value of warranties that I recently reread. I'm surprised the shingle manufactures haven't stipulated that you can't fart upwind of there product yet.

I'm going to visit the triflex site and see what that's all about. All in all the concept of a more durable and easier installing felt obviously has a ton of merit.

But there you have it Miike. That was the first thing I thought when the rep gave me the v.b. b.s. This could turn into a vent/non vent flame war if were not careful.Tom

Mike,

the people at the shingle plant told me that they felt that the" controlled shrinkage"might pose a problem with "uplift" in valleys.although I really like the idea of 5 ft. rolls of underlayment,the rooftop gaurd was very " curly" and I found it to be a real pain in the A_ _ to install on steeper roofs.

right now I am sticking with 30# felt,--but I am waiting for some samples of a "light buff" colored underlayment that uses no asphalt( I think it is fiberglass)I haven't seen it yet,but it sounds like it would keep the roof surface cooler and more comfortable to work on.my shingle manufacturer already ok'd it.

Anybody tried the GAF fiberglass reinforced equivalent to #15 tarpaper? It is called "Shingle-Mate". I've never seen the stuff in person, having only dealt with #15 paper, but I imagine it is like the roofguard in some ways.

Shingle -Mate is GAF's answer to Certainteed's Roofer's Select...... which is what we used instead of 30# felt..both are fiberglass reinforced felt.. much stronger than regular 15# and it lays back down after a rain, which 30# won't do..not a problem if you cover with shingles as you lay it.. but our roofs stay papered in for weeks at a time.. so we need something durable and weatherproof..

the controlled shrinkage in the valleys is true.. but all you have to do is not nail it on the other side of the valley.. we got no more bridging from that than we do from felt that is improperly spanned across the valleys..

all -in- all... we'll use Rooftopguard until something better comes along.. and i put a call into Flexia for some more info...my guess.. we'll be using some one's roof-fabric in 5' x 10 sq. rolls... if not that, then Roofer's Select with roofing tins

Mike Smith Rhode Island : Design / Build / Repair / Restore

Edited 8/1/2002 5:24:30 PM ET by Mike Smith

here's a pic of the Roof TopGuard on one of our works-in-progress... we got the new stuff about two weeks after most of the roof had been papered-in..

the older 15# felt is showing a lot of wrinkles and tears.. the new stuff is nice and tight, easy to walk on.. and showing no signs of deterioration..if the whole roof had been done with it.. i'd feel a lot better...Mike Smith Rhode Island : Design / Build / Repair / Restore

Mike, that long wrinkle near the top in the 15" paper?

That is something I get less of with the diagonal nailing pattern I drew in the first post. Yours are all in a straight line down the middle of the roll.

Not that we'll be needing to worry about it. I'm going to be looking for the topgaurdExcellence is its own reward!

when we're papering in..we tack the roll with 3 nails.. pull it tight and tack it down then one guy places the tins and the other guy nails with the roofing gun... pretty fast..Mike Smith Rhode Island : Design / Build / Repair / Restore

A variation to Boss' string and staples, roofing nails and nylon strapping.

Tom