I like using pocket doors as solutions for doors with no good place for a swing, but I don’t like the flimsy feel of one done in a 2×4 framed RO, with only those sheetmetal-wrapped sticks as wall frame for the pocket.

Having used a couple techniques for beefing up the pocket walls, I thought I would solicit ideas for more ways.

Shown here are two ways I’ve done it, and one that I have considered.

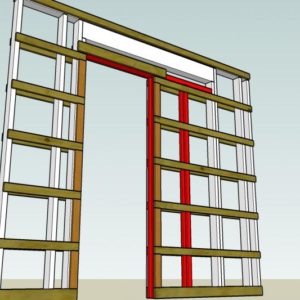

The pic “pocket 5Q” has a 2×6 frame for the wall, and 5/4 boards are used to fur out the pocket to the face of the studs. Pretty easy, pretty fast, and no ripping of any material required. In lieu of buying 5/4 stock, you can just rip some stuff out of framing lumber on your tablesaw.

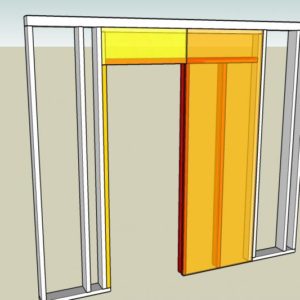

“Pocket ply” shows how I’ve done it using plywood over the pocket panel, but to use 3/4 CDX, you first need to rip your 2×6 framing to 5″, taking about as much time as if you didn’t rip the framing, but cut twice the ply panels, sheeting the pockets with two layers of 1/2″ sheet material.

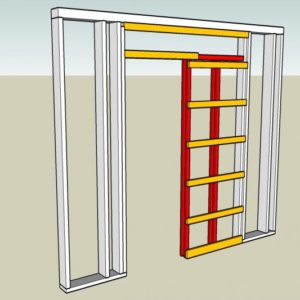

Then there is the use of 2×4 for the whole wallframe, then strapping the whole thing with 1x strips, shown in the pic “pocket frame.” I haven’t done this, but it may have some appeal to the New England crowd, who seem to strap everything. Everything.

What do you do?

Edited 7/8/2007 7:34 am ET by Gene_Davis

Replies

Gene, the last pocket door I framed was a double 3/0 opening. I had the room to go to a 2x6 wall, so I did, and installed 2x4 studs on the flat in the pocket area. This was a 16' long wall so there were a few 2x6 studs at either end, but most of the length was consumed by the flat framed opening area. It worked very well. You get a pocket that is plenty wide and if you choose studs carefully it is flat. We rocked with 5/8" both sides. The feel is very solid.

Never did the math but I guess you could shave it down to a 5" plate if you wanted to rip framing lumber, and if I could get appropriate 5/4 I might try that too. The 5/4 here is VG fir.

Did a typical Johnson pocket door with the cheesy metal-wrapped "studs" on the same job, a water closet door. Very flimsy stuff by comparison, barely even tract house quality.

I like doing it whatever way I can get electrical boxes near the jambs. Sucks when double pocketdoors get installed and you walk 3 and 1/2 feet tryig to find a switch

We had problems with pocket door frame bowing inward toward the door. It was finished wall and when the frame made contact with the slider, it left marks on the door. What a pain. To solve our problem, we tried to frame all pocket door walls with 2 X 6 lumber then we did what you did in your first example or covered with plywood and fur out the plywood flush to the rest of the wall. When we furred out the frame with 5/4 material, like you suggest in your first example, we did it vertically from floor to ceiling and we always added 3/4 plywood between to ease addition of TP holder or whatever. Never had problems with frame contacting slider after that. We also used trim head screws on one side in the overhead trim above the opening to allow later access to the door if it needed adjustment.

The whole thing was a pain to do and required a lot of extra time but the extra time was more than made up if we had to fix problems later.

Gene,

this is what it would look like in real life.

http://www.josephfusco.org

I am not sure what all the extra strapping would add for strength there.

Using studs turned sideways to gives plenty room for a work box and wireing

I have never really had much trouble getting solid walls with Johnson stuff. Every now and then there is a poor steel wrapped stud, but I have done so many of them where I need to use my own studding or plywood instead, I always have some of those left over. Probably 5 or 6 six in the shop attic right now.

But when it has to be a 2x4 wall thickness I use their wrapped studs.I do some things that does make it work out stronger though.

Sometimes I use an extra pair so the layout is closer.

But the main thing is that when we hang the SR, we rip a couple of shims that are about 1/4" wider than the door space is supposed to be - about 2-1/4" We fit them in where the door pocket is betweeen the kit studs. Then we use PL premium on the studs.

What this does is to introduce a lamination bow out slightly to the assembly that makes it somewhat stronger against lateral loading in the way that crown ups on floor joists resists loading better. It also gives insurance that it is less likely that the kit studs will ever warp the wrong way.

I work in a lot of older homes where the old studs are full 4" or 3-7/8" + lathe. So my favorite trick there is to use the Johnson door frame and then go over that whole assembly with 3/8" up to 3/4" plywood, glued with the introduced crown/bow. Thickness of the plywood depends on what I need to make up the wall thickness flush to the existing. Then the SR or plaster board over that.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

For a 2x6 wall I'll have roughly 3 verticle 2x6's on edge on each side of the pocket roughly 10" to 12" oc.

The 4 studs closest to the opening are ripped down the middle, on side is turned 180 degrees and they are glued and screwed back together. As the stud dries the reversed grain counteracts much of the crowning.

Any structural header is installed as high as possible and the studs are run full height to the bottom of the header or top plate. Full height studs will be twice as stiff compared to those cut the height of the opening.

A center floating door track header is ripped to 2-1/2" (5-1/2" minus 3" for the studs) and long enough to span from back of pocket completely to other side of door opening and doubled up for stiffness. It's fancier to cut it wider at the door opening so it serves as a sheetrock and door trim nailer, but that can be added as scrap 2x as well.

The key to this system is the floating track header. When all the studs are screwed into it they lock the whole works together into a door opening that's very stiff. This type of header is also extreamly easy to level. Since the floating header also spans the entire pocket opening it counteracts any bending on the studs so the studs are locked in at top bottom and sorta close to the top.

It takes about as long to frame this way as it does to write it up and in 10 years of custom building I have yet to see a faster and stiffer method for 2x6 construction.

Best

Beer was created so carpenters wouldn't rule the world.

You could get 3/4" wide 16ga. cold rolled steel channel, glue and screw it to the edges of the existing pieces. Stiffness without adding size,

Rebuilding my home in Cypress, CA

Also a CRX fanatic!

Parenting has always been a mix of sage life advice and inexcusable laziness.