Is there a webpage that explains the different sizes and pitches of machine screws and bolts? For example, does M8x1.25 mean that the screw is 8mm in diameter, with 1.25cm of length for every 10 threads?

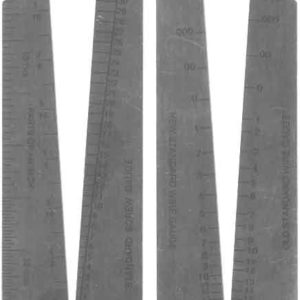

I have a screw gauge (see attached) but it doesn’t explain thread pitch or metric hardware.

—————————-

On a related note: I needed to replace one of three identical bolts, so I brought one to the hardware store to match. The clerk tested the bolt against an assortment of nuts until he found one that fit, which told him which size and pitch of bolt to use.

The replacement bolt serves the purpose but, oddly, it is slightly larger than the other bolts, both in thread diameter and the size of the hex head. Don’t all manufacturers put the same size hex head on a particular size of bolt? I’m wondering if it’s the wrong type of bolt–American instead of metric–and happens to be close enough to fit.

Janet

Replies

You need a couple of thread pitch gauges...one in American, other in Metric. looks like a metal book of saws. put the teeth on the bolt till they match up mountains in valleys. Read the gauge, it will tell u the pitch. then put in size gauge u have to get the diameter.

M8 does mean that it is NOMINALLY 8 mm; i believe that the 1.25 is threads per some length.

If you are working with inch-dimensioned MACHINE bolts, there is a handy rule of thumb: the size of the hex head is 1.5 x the bolt size; so a 1/4" bolt will need a 3/8 wrench; a 1/2" will need a 3/4; etc etc. But that is for standard machine bolts.

Metric threads are specified as diameter in millimeters by thread pitch (distance between adjacent threads) in millimeters. So yes, the second number is the length in centimeters of 10 threads, but that's not how it's defined.

>> Don't all manufacturers put the same size hex head on a particular size of bolt?

There are standards, but there are also standard variations. For instance, a heavy duty bolt in a given thread size might have a larger head than a standard duty bolt. As far as the thread diameter, it might just look larger. If you have one black bolt and one shiny bolt, one of them will look distinctly larger, to me at least.

>> I'm wondering if it's the wrong type of bolt--American instead of metric--and happens

>> to be close enough to fit.

It happens. I don't remember right off the top of my which ones they are, but there are several cases where the inch and metric threads are close enough that they will screw together for a few turns. If the nut is thin, that might be enough. There are also a number of head sizes where inch and metric wrenches can be used interchangeably.

A standard reference is Machinery's Handbook, 1200+ pages of information about machines and machining. Your library may have a copy. It's about US$75 new, but older editions, back to the 1920's, can be found on eBay for substantially less.

Here's a link to a picture of the kind of thread gauge Jim is talking about. http://www.jewellerytools.com/gifs/tg101-zoom.jpg

Edited 1/1/2003 8:45:43 PM ET by Uncle Dunc

And here's an answer to your original question. It doesn't explain much, but it does at least list a wide selection of thread sizes.

http://www.engineersedge.com/tap_drill_chart.htm

I don't know of any web sites but you will find the information in the machinists bible: "Machineries Handbook" available at most libraries and some book stores. When I worked as a machinist I used it quite a bit.

http://www.amazon.com/exec/obidos/ASIN/0831126256/qid=1041485340/sr=2-1/ref=sr_2_1/102-6396261-7422556

More to learn here than I had expected! I searched online for a pitch gauge for regular screws. It turns out I need to know what type of "regular" screws the gauge will measure: Whitworth, American National Thread, Unified Screw, or Acme.

So I decided to buy the metric gauge first because metric is metric, right? Not that easy: The screws could be just plain metric, SI (Systeme Internationale) metric, or ISO (International Organization for Standardization) metric. They don't appear to be interchangeable:

Which regular and metric systems are most commonly used?

Janet

Flip through Machineries Handbook and a good manual on smithing. You may find it is less, and more, complicated than that. Less, in that the vast majority of fasteners come in only a very few common patterns and only a fraction of the possible sizes. More, in that there are many obsolete and seldom used standard sizes and patterns available.

Also threads formed before the 1900s, sometimes as late as the 30s, were commonly custom formed by a blacksmith or metalsmith by rough forming a spiral pattern on a rod and then then twisting this through a red hot nut to form a threaded and quite usable pair. These are true works of art but, as with art, not interchangeable often even on the same machine.

>> the vast majority of fasteners come in only a very few

>> common patterns and only a fraction of the possible sizes

There are websites that list "first choice" screw sizes: M4, M6, M10, M16, M24. I think they want all manufacturers to make the same few sizes, as a step towards adopting global standards.

Janet