Tile over plastic door threshold w glue?

Gang,

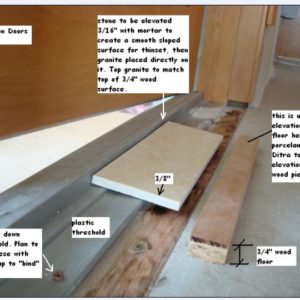

I’ve got a good one here. I have flooring that goes up 3/4″ from gypcrete butting against an Anderson french door. The problem is 3/4″ high flooring does not match with any of the plastic door threshold tiers that comes with Anderson doors (see picture). Besides, the plastic threshold was bucking up anyway, so I screw it down to keep it solid. Here’s the problem:

To cover that plastic threshold complex, I would prefer to just place black granite in that 5″ section ramping up from top of wood to top of door threshold. But I would be tiling over PLASTIC door threshold and wood. I was thinking to improve my substrate stability, I would screw down the plastic threshold tight with lots and lots of wood screws. Then I would also have a number of screws placed with its head sticking up enough to allow thinset (or should I use feather mortar?) to bite into, then tile over that.

Has anyone tried anything like this before? Wondering if this would work to give me years of trouble free use or would it be an annual maintenance nightmare for me to deal with.

The other option is to glue down the granite with construction adhesive. Liquid nails or the likes will probably bind it pretty good after I screw down the plastic. Thoughts?

Replies

Greetings Steamline,

This post, in response to your question, will bump the thread through the 'recent discussion' listing again which will increase it's viewing.

Perhaps it will catch someone's attention that can help you with advice.

Cheers

Good question.

Let's run this by again.

Cheers

bump

Both plastic and plywood? subfloor will move a lot, and a layer of thinset will not hold the stone. How about these ideas:

1. Cover the wood subfloor with hardi and then cover the whole strip with expanded metal lath and nail every 2 inches? Skim coat over the lath and when dry, install stone with thinset. This may give the thinset better bite and adhesion for the stone. Don't use grout. Seal the joints with color matched caulk.

2. Instead of stone, use wood to cover the strip such as oak or ipe. Ipe may be better under the traffic but I heard very hard to stain. Instead of screw heads sticking up, countersink to make the plastic surface as smooth as possible then use flexible adhesive such urethane and float the wood threshold. Hold down the wood with bronze or stainless screws and make the screw holes bigger than the screw. These steps may tolerate the movements better than trying to hold everything down tight. Back gouge the wood to make up for thickness differences and use the adhesive to float the wood. Hope this helps.

K1C,

I like the ideas, but think I have to modify it because the combination of hardi and stone will make them stick out about 3/8" higher than the main floor itself. What if I metal lath directly to the plastic and wood bottom at 2" screw intervals. Use cement designed for thin surfaces to build a slope on top of the plastic and wood substrate on the lath. I can then thinset directly on the cement/lath combination, and caulk to tie back to the main floor as you suggested. Even if the wood/plastic subfloor moves below, the stone on top would move also and won't break the caulk bond. Thoughts?

Just protect the exposed wood with some tarpaper and I think you can lath over the wood as well. Make the lath-layer as thick as possible, using fiber reinforced mortar. Mortar is probably stronger than the bed of thinset. If you bevel the stone edge, maybe you can put the stone little higher than the finished floor. Stone must be level so the heel will not slip on the first step. Hope this helps.

These are great suggestions. Based on this, I think I will do the following:

1. Cut out the plastic portion of the Andersen door threshold.

2. Protect the wood with tar paper. Metal lathe over it. Mortar thick as possible while building a slope to guide wheel chair to top of metal door threshold. QUESTION: Where would I buy fiber-reinforced mortar mix? Sloped floor helps with the wheel chair rolling over the door threshold, but does pose a risk with heels. I'll keep the slope as low as possible then.

3. I did not prime nor sealed the gypcrete - ditra interface. What would be the consequence of this. I hope the ditra does not separate from the gypcrete as a result.

4. Good point on ditra acting as an insulator of heat. With 3/4" wood flooring in adjacent rooms, I had to use ditra to "lift" the floor a little, in addition to the antifracture benefits. How did you secure 1/4" hardie to the gypcrete? Mine has hydronic radiant tube in gypcrete so penetration is a no-no for me.

"Stone must be level so the heel will not slip on the first step."I agree absolutely with that! Putting a bevel in the finished surface with this material at a potentially wet location is an injury lawsuit with the ambulance chasers waiting in the wings or even affixing their business cards to the door itself.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I like your picture ... makes the situation much more clear.

You show a 3/4" thick guage block, and say that ditra and porcelain will be that thick. That's some pretty thick porcelain tile.

"Put your creed in your deed." Emerson

"When asked if you can do something, tell'em "Why certainly I can", then get busy and find a way to do it." T. Roosevelt

The main floor is 3/4". The porcelean is 3/8", ditra 1/8" makes 1/2". The remainder 1/4" is for the thinset below the ditra and above the ditra, so it isn't a stretch at all to make this work.

Ditra with 3/8 tile and thinset comes to 5/8" in my experience.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

I like it too, except that it raises other questions for me as mentioned above.Looking more at it, I wonder if the main floor area is gypprete and the ply I see is a shim rather than subfloor.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

Your main question seems to be regarding tiling over the plastic threshold. I'm no professional tiler but that doesn't seem to be a good idea to me even with the screw anchors. Can you cut the threshold out? A Fein multimaster would make quick work of it.

Does the gypcrete cover radiant heat? If so, you might want to rethink the Ditra as it will most likely slow down heat transfer. I have a similar situation in my own bathroom. I used 1/4" wonderboard over the gyp. Then thinset the 3/8" tile onto that. The gyp should be primed first. For that matter, it should be primed first if you use the Ditra.

first problem I see is water staining on the subfloor which indicates to me that you have leaking around the door installation. There is no pan liner there. So the buckling you desriube in the 'plastic' thresh is likely from water in the plywood under it.

So fix that problem first. Take the whole door assembly out - make sure that it was put together WITH silicone caulk or geocel in the joint between jamb and thresh, then install a pan under things, and reset teh door asssembly in the caulk.

now I read the rest of the thread to see what other ideas are in ply.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

If that plywood we see is indeed a shim of some sort, you could reset the door on a different shim or one dadoed to bring th e door flush with where you want it to make a leveled entry for a wheelchair.

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where ...

Excellence is its own reward!

About that plastic, it may be there for purpose. Do you think it is some sort of pan or reinforcement for the door? Contact the manufacturer or check the specs in their website before you cut it out. They may even specify that plastic part has to be left floating. Consider the movement of plastic (especially in heat) before you make changes to that part.

Also, if you need smooth transition for a wheel chair, you should come up with another plan. That stone should not have slope at all. Either that, replace the stone in the picture with rougher surface stone, maybe slate. Put a bevel on the edge that meets the floor and install the stone higher, even if just 1/8 inch. Either way, if you can see the slope by eye, without cheating, it is too much for the situation. 1/4 round molding may help, but do not slope this part for the wheelchair's sake. Good luck.

I have provided an update photo on the tile work so you can have a closer look. The black patches you see are not water stain. It's my grinding mark to make the wood level with the gypcrete (and burnt wood as a result.) There won't be any water intrusion here from the weather because there's a 16' covered terrace just outside these double doors. BTW, this is new construction.I placed a black piece of granite to highlight what I want to do here to create a sloped transition. I recognize that sloped tile is not ideal, but it serves 2 purposes: allows tile to butt up against the threshold gracefully, and wheel chair friendly. Even if we ignore the wheel chair benefit, I find it difficult to tile to the plastic threshold because there isn't a good way to butt the tile against it properly without looking ugly. Anderson rep says I can cut out the plastic part as it serves no functional benefit once installed, but it will void my warranty. I can forgo the warranty part (almost impossible to get anyone to honor warranty these days without the blame game anyway). But it will create a slight slope. Your advice is not to do it? The stones are very slip resistent, even wet. That' why we got it. It's surface is rough. So, if I cut out the bottom plastic lip (where the screws are at, then I can have a flat stone surface to the whole floor. My concern is that the upper plastic lip will have nothing to prevent it from warping up (as you can see the bottom plastic is doing already.) I can take this risk, and just caulk the plastic/tile joint when complete. Question: For the wood portion, would I still use tar paper, metal mesh it secured with lots of screws, then scratch coat it with mortar, then thinset with tile. Is this the proper way to tile over this strip of wood? Is there not thinset that allows me to bond directly to the 2x4 wood so I can bypass all this paper/lathe/thinset complex? I prefer to go wood - Ditra - tile just like I have for the rest of the floor. Thoughts?Thx.

Is it too late to remove the door, lower the substrate under the threshold and reinstall the door? From the photo it appears there is enough room to clear the bottom of the door.

You can also remove the offending plastic section which you shouldn't tile over anyhow and the lowered threshold will accomodate the tile without the slope.

The doors are in for good and are stucco'd over at the outside. I can remove the lower plastic part and tile on the wood to keep the surface flat. This appears to be the concensus now.

It does seem to be the way you are going - with your blinders on. I don't think it is the concensus.You may have to go that way since you have things all stuccoed in, I can't see all that from here, but I think you have historically and classicly forgotten to do some detail advance planning on all of this at the right times and are now in process of finding ways to work around the oversight instead of stepping back and making the adjustments needed to make it all right.

Not a criticism, and I may be wrong - just an observation.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

The cabinets are shimmed 3/4" and dimensions are fine with the dish washer. There's a lot to plan and I admit building my own home is a lot of work in all aspects of construction. Without having live through some of this stuff before, there's a lot I would have done differently. However, I don't see how this particular situation is unique in any houses that use Anderson doors next to gypcrete where the stone and 3/4" wood flooring needs to match. The house is designed with double plated 2x6" on all the walls sitting on top of the plywood substrate. The bottom plate is the dam for the gypcrete. The top plate is for the sheetrock nailing. What you are seeing below the door threshhold is the 2x6 acting as a dam for the gypcrete. The plastic is warped a little because the doors were not set flat by the framers and these doors have lots of adjustments that compensate for that warp, but the plastic bucking up is a result of the non-planar install.Did I mis-read the advise provided? I understand that sloped stone surface is not recommended so I would be cutting out the plastic to accomodate a flat stone surface. Piffin, would you just continue ditra over the 2x6 and tile on top of that without tar paper? Can thinset bond on 2x6 directly or is there special treatments I need to do. Sorry for asking seemingly basic questions, but having to deal with foundation, roof, electrical, engineering, codes, etc.... tiling is not an area I am well versed in thus needing all your inputs.

OK, So I would have planned by dadoing the 2x6 or using something else to avoid all this by having the door set that much lower, and installed right instead of unevenly.That aside - yse - ditra is designed to function as a separation membrane and is good for spanning over changes in materials like this.The only concern is that you chose whether to use modified thinset or unmodified based on the substrate. See the labeling.but I doubt that for such a small spot, it will really make too much difference.If you did use a mortar with lathe instead, you DO want tarpaper on the wood.I like the look of that stone.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

One issue you mentioned in the OP is yet unanswered - you said the threshold is buckling on you. Why is the? Unless that is adressed FIRST, the rest of this is academic.IMO, Ditra is the answer to dealing with the transition to wood once you cut the composite threshold strip.are your cabinets shimmed up the thickness of this flooring?t you are facing a problem with appliances like dishwasher.

Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where ... Excellence is its own reward!

The threshold being the first step into the house, it is more important than generally assumed. It is almost the same as the rules for making stairs. Most people don't look at this part and you have to make it as safe as possible. I really think anything sloped at this point is bad idea, especially covering that much area. Would you consider cover some of that part with metal threshold? I see two steps in the plastic part. If you cut the larger step, take the stone to that line and look for most attractive metal threshold to cover the gap? Then again this may not work for french door. Put a bevel on other edge, bring the stone little higher, and cover the gap with metal that is used to cover carpet or different level floors. Go into lumber yards and ask for specialty companies that offer better grade of these materials, not just HD.

Would cutting that plastic completely make the jambs prone to twisting? If you can cut that part, I would reinforce the bottom parts of the jamb with screws (you can hide the screw with wood caps).

I think you can use whichever method you prefer to install the stone, just watch the finish height. I would think lath and thinset have the most to forgive if you misjudge the height. For this area, you can use anything except installing directly to wood. For one thng, wood will soak up too much water from thinset so thinset will not cure properly. I never tried or read about thinset applied directly to wood. I think that maybe some modified thinset that can be used over prepared wood floor. That is, wood floor that is somewhat flexible (to tile engineers) but overlaid with cement board or mortar bed. Good luck.

K1c,

That's an interesting thought - placing 1/4" hardie over 2x6, then tile on top of that. Finish surfaces would match! I think hardie on wood is an acceptable application, correct? There's that 1/8" that tile would be higher than the upper plastic once the large plastic is cut off. I could put a small strip of ipe there, rip it thin so it flushes at the finish level, and glue that down with construction adhesive to the plastic below. Thoughts? Thx.