I’ve been trying to come up with a creative solution to repairing the bottom surface of the ~6×8 sill timbers on our 120yr old house at the sill/brick interface. Also, I would like to add a capillary break so that I can move forward with insulating the interior of the basement without putting the sill at greater risk. I’ve seen various methods employed for such repairs in online videos, all of which entail jacking. I’m looking to avoid jacking if possible, and keep it DIY friendly.

This is what I’m considering:

-make a 2-part saw guide (jig)

-drill 2-3 starter holes near the bottom of the sill for the sawzall blade entry

-drill an “exit” hole ~12-18″ further down the sill

-attach the saw jig to both sides of timber with screws

-using guide, saw slice of timber ~1/4″ thick up to the “exit” hole

-remove jig and remove waste wood piece

-dry area to appropriate moisture level needed for epoxy

-dam and fill cavity with Abatron. Wood Epox / repair product

-once cured, move on to next section. Rinse / Repeat.

I believe that repairing in small intervals (1-2ft) would support the structure and not bind the blade, but I could adjust as needed. This process would also allow for a piecemeal approach from a timing perspective.

If I encounter more severe rot in places I can adjust the degree of excavation as needed. I have done a preliminary inspection and don’t believe I’ll find too many areas that are severe.

Does anyone here have experience with the Abatron product for such a repair? Or have a different recommendation? Ideally I would want something with ~zero permeability so that I could use the epoxy as the capillary break without having to add a separate membrane.

Aside from needing further development and testing, does my “high level” plan seem reasonable? or is there a better way home?

Thanks!

Replies

I'd like to see some photos showing how much access you have to these areas and also how the studs and joists interact with the sills.

Most older houses are a lot tougher than you might think. You may be able to remove several feet at a time, replace with treated and wedge the framing back tight afterwards. I get a feel for how much weight is on a member by how the saw binds while cutting nails. Other areas like the corners may require jacking to replace even a short piece.

I'm a power user of abatron products. I can recommend them wholeheartedly. The liquid can convert termite poo into solid structural material. The trick being application. Mixing the liquid woodepox with planer shaving and or sawdust is great for filling larger voids. The solid version is better for finish type work like architectural parts.

Thanks 2sheps, I appreciate your input. Great to hear that Abatron is recommended.

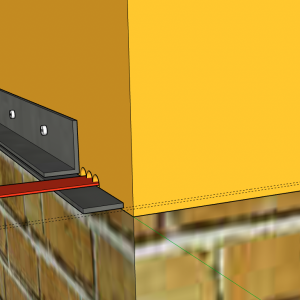

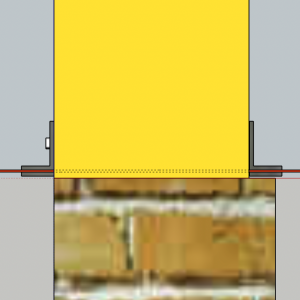

I attached a few pics. There are some obstacles, however, most are manageable. Certainly where the joists are perpendicular to the sill will require extra finesse with the cutting.

The joists are let into the sill timber mortises (similar to a half lap joint). The tenon shoulders are at mid-depth of the joists. Some areas need attention due to stress cracking at the corners where the tenon extends from the joists. I plan to tend to these areas as well with hangers and additional support. The to-do list is lengthy!

The studs are toe nailed directly to the sill timber. On the outside the board sheathing and siding (original wood+ vinyl) extends down to the bottom of the sill timber.

I have not contacted Abatron yet to inquire; do you know if the woodepox would be sufficient to serve as a capillary break?

Thanks again.

Thanks for including the pics. That looks a lot better than I had envisioned. Compared to some of the things I've come across that's new lumber :)

If there's no significant settling, I wouldn't replace any of that.

I'd at least try drilling some 1/8" (or so) holes along the bottom edge at a downward angle every inch or so along the suspect areas. Then put the woodepox in one of those dollar store mustard/ketchup bottles and squirt it in those holes until it wont take any more or you see it running out the bottom. Be prepared to catch any runout with a rag or towel as you don't want it running down the stone or brick.

I can't answer the capillary break question on a technical basis but I can say that any wood impregnated with woodepox should be waterproof for many years.

Also, the abatron is fairly slow to cure when cool. Think in terms of hours or days rather than minutes.

One possible downside may be that the sill will be bonded, rather permanently to the foundation.

Thanks again. Yes, the sill looks decent in most areas, though the bottom is punky, but only for a short distance in most areas. One of the reasons I wanted to get a capillary break in there was because I would like to do some insulating on the inside of the basement. I'm not comfortable insulating the sill area without a capillary break under the sill. It seems it would be risky to trap moisture in the sill area, even though it "could" still dry to the outside. It's a large timber so I think the more it can dry the better.

I did find, and tear apart, one area of the sill that looked fine from the exterior, but fell apart easily once I started poking. The pith was centered on the timber and moisture sucked up the end grain and it rotted at the center, though the faces looked fine. It was at a spot that was very close to grade, so it was not surprising.

I'll likely due some smaller scale testing with the woodepox and see how things go. Maybe some holes as you had suggested.

Good info regarding your experience with the curing. Also, interesting thought about the bonding as well....who needs anchor bolts :)

Thanks