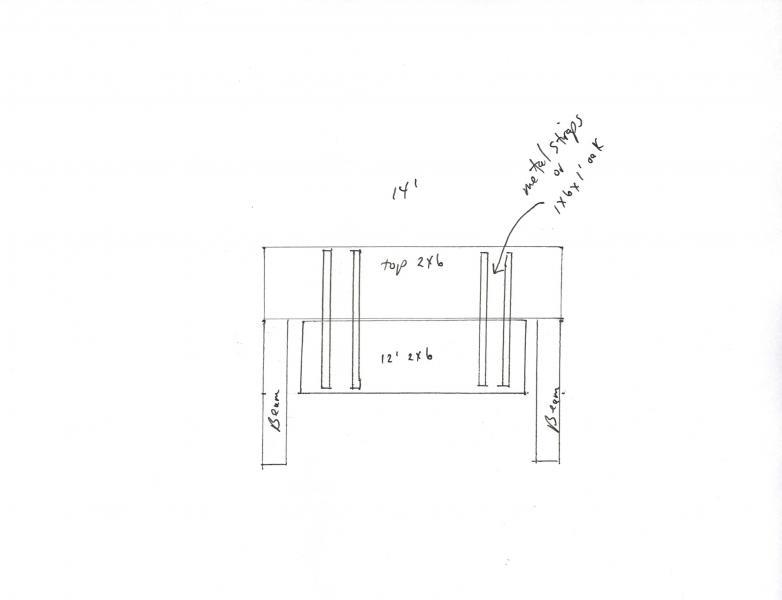

I want to span a true actual 2×6 about 14′. I was looking for a way to strengthen this along the following line. Take another true 2×6, about 12′ long  and secure it edge to edge to the bottom of the main 2×6. Secure it with either metal straps down the side of both 2×6’s or maybe take a 1×6 oak, cut about 1′ and nail it to each side of the 2×6’s. Sort of making a truss out of it. The top 14′ 2×6, would be resting on the beam at each end. Seems like any down pressure would need to bend both 2×6’s to get a sag, Thoughts?

and secure it edge to edge to the bottom of the main 2×6. Secure it with either metal straps down the side of both 2×6’s or maybe take a 1×6 oak, cut about 1′ and nail it to each side of the 2×6’s. Sort of making a truss out of it. The top 14′ 2×6, would be resting on the beam at each end. Seems like any down pressure would need to bend both 2×6’s to get a sag, Thoughts?

It is for ag purpose and no permit required. Will be rafters, Just regular roof load. Light snow. 2′ on center. Wood is Popular.

Replies

Ditto what Mark said.

If you could rigidly attach the two together in that configuration (effectively glue them edge to edge) you'd have beam that is 4x the strength of a single one.

If you do not rigidly attach but can (eg, using multiple straps) get the bottom beam up nice and snug against the top along its full length (but there's nothing much preventing them from sliding sideways relative to each other) then you get 2x the strength of the single one.

If you can't get the bottom member up snug then you don't really help things much.

Placed side-by-side you get 2x.

There is wrong advice being given in this few posts. Yes it works kind of, but you need to talk about the connection details with someone who really understands what is happening.

IMHO: If you are sheathing with plywood you would get better moment strength by making an upside down Tee. The sheating prevents the top from buckling under compression, the bottom ot the Tee gives a wide section acting at the bottom under tension in the area where the moment load dominates.

And, are the ends going to be strong enough in the shear zone at the ends to resist the load?

I can't stress this enough: Talk to an Engineer.

What?

I'm sorry, but you really need to go back to the drawing board. Better still go to an engineer or at least to someone that is knowledgeable about about constrution principles.

Is your intent to try to make a 2x12 or a 4x6? That is, through the 12' length. It's given that the ends will be simply a 2x6.

Yes, for the length of the 12' 2x6, it would actually be a 2x12. The extra foot or so on each end of the 14 2x6 would be a 2x6. The shear strength should be fine on the ends. Just trying to prevent a sagg. The will only be 1x4's and metal roofing on top. Plus any snow.

Yeah, to get the effect of a 2x12 you'd need to very rigidly connect the two planks. Probably plywood glued and nailed/screwed would be the simplest approach (it could be two 6-foot pieces, and probably 3/8" thick would be sufficient).

Joint the two mating edges and glue them together with titebond. You'll have a 2x12. If you can't get a tight joint then you'll have to use thickened epoxy. But then, for all the expense and trouble, you'd really be better off going out a purchasing some 2x12's of the correct length.

it doesnt matter if you glue 10 on you still only have 1 2x6 bearing support.

A horizontal beam, evenly loaded, does not need to be as strong/stiff on the ends as it does in the middle.

i think we are talking about different things here, dan.

If you knotch the end of a 2x10 to place it on a 2x2 ledger, you just made your 2x10 a 2x8. same thing here, if he only has a 2x6 bearing, he only hasa 2x6. there is a reason why we dont just cut up some 2x4's and make our own trusses....well at least why we shouldnt!

Yeah, we're talking about different things. I'm talking about beams, strength of materials, all that crap I learned in engineering school. I can't tell what you're talking about.

The only rafters that can span over 14' are: (14'1'') a select structural souther pine (14'4'') douglas fir and these spans are only when no ceiling is attached to the rafter.

If you were to manage a succesfull system to couple the two 2x6's and in turn make a "2x12" then you would be looking at a 2x12 with the bearing ends knotched 50%.

i just dont see how that is ok...am i overlooking something?

have been know to be wrong, ask my wife!

So, how is it that this bridge stands:

View Image

Notching the ends only affects the ends - The the whole member.

I often disagree with Dan. But in this case he's right.

Both beams will support the load, but as two 2x6 beams, not a 2x12. You need to make a shear connection between the two beams along the entire 12' length to get them to act as a 2x12. You can add diagonal bracing to make it a truss, or make it a plywood/lumber box beam. Otherwise, you might just as well put them side by side.

The APA has free publications that explain it all. You will need to register to download, but at no cost.

Nailed Stuctural-Use Panel and Lumber Beams Form Z416

Design and Fabrication of Glued Plywood-Lumber Beams Form S812.

http://www.apawood.org

Same principles, different material

mark122 wrote:

really? wonder if that bridge is made out of polar????

The forces (tension, compression, bending, and shear) that act upon steel, act the same upon wood. The difference is in their capacity to handle them.

and your point is...

rr,

Nail and glue the second 2x6 an 1 1/2" down on the first. Should span 14' with no sag.

KK