A while back I fooled around with a design I saw in an article in Better Homes and Gardens magazine. It was a nice shingle-style cottage with a cross-gabled roof.

The way the program went for the inside spaces, I went crazy trying to work out a way for the roof to be framed. There seemed no reasonable way to get the large loads from the inboard parts of the ridges and hips down through walls, all the way to bearing.

As an exercise for learning more features of my Chief Architect software, I modeled the house, then started to figure out the roof framing.

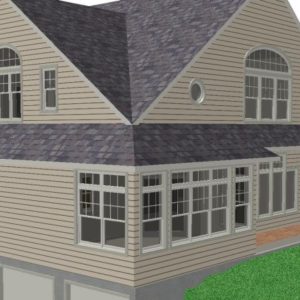

Here is a view of the house. The upstairs walls on which the roof bear, form a rectangle of about 37 x 44 feet. There are four rooms that look out through the large gables through feature windows, two of which are shown here. Those rooms have vaulted ceilings, but those ceilings spring from an eight-foot height, with lower pitches than the 9-pitch roof above, so there is some nice overhead between ceiling and roof with which to work.

I tried out a stick-framed design, using 2×12 rafters on 24″ centers, with heavy LVL structural ridges and valleys. The wall layout below, not easily changed without compromising the whole arrangement, afforded some posting down from the structure, but there was nothing below on the main floor for continuing the load paths.

I was stuck with perhaps doing some complex thing with steel in the floor frame of the first floor. Yuk. No good.

This pic shows the array of posts under the stickframed roof.

So then I thought, “Let’s see how some engineered truss schemes might work.”

Replies

Continuing the thread.

I schemed up an arrangement of trusses, with large heavy girders spanning the short direction across the roof. Spanning between them are short scissors trusses, with plenty of depth, that follow the peaks as required, of the lower cross gables.

Each of those cross gables has a set of girders, junior versions of the biggies, but they hang to the biggies on their inboard ends. Each valley corner, about a 12x12 area, is stickframed with an LVL valley and 2x12 rafters.

Here is a plan view of the second floor, showing the truss layout, and the upper L corner evidences the stick framing.

View Image

I did not do it in the plan, but the big girders will probably be triple-ply things with heavy chords. Chief's software does not give me the control of truss chording the way a truss engineering package does, but it at least gives me control over the truss envelopes. Here is a section cut showing how the girder might look. It is 3'6" high on the parallel-chord ends.

View Image

A 3D view of the truss arrangement is shown here. The stickframed corner valley is in the foreground, and the other three are not shown.

View Image

And finally, an Xray view taken inside the master bedroom, to show how the scissors are framing for the vaulted ceiling below.

View Image

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

Gene,

Do you have the second floor layout to show?

If there is no way of posting down at all, knowing this obviously will be cathedral, could you run the 37 ridge as a structural ridge underneath the 44' ridge posting down to that one? Just a quick thought without seeing the second floor floor plan. Doing that would obviously change the look after it's sheetrocked, but you would have two nice big beams for a finished product that might not look bad.

I may not understand all that your trying to do, but Michael Chandler in FHB #178 used an angled flitch plate for a cathedral hip.

Use the angle flitch in the valley LVL's that extend to the top ridge and they will become the beams that hold up everything else.

The roof weight is then on the four corners of the house, with an open cathedral upstairs.

I'd drop a ceiling parallel to the roof for insulation room, drywall and blow the insulation.

Framed with LVLs and sawn lumber, those hips, the long ones that homerun from the corners to the ridge, are about 37 feet in length.

For the headroom to work in the few living spaces the hips pass over, they cannot be any deeper than about 13 inches.

A structural ridge needs to be designed for a 36 foot span, and at our snow loading, would be looking to carry about 1700 pounds per foot of total load.

A three-ply LVL at 20 inches of depth won't even handle half of that at that length.

It would take steel, and then the reaction load for the end bearings, occuring dead center over large feature windows below, would be about 30,000 pounds. A quite heavy column, bearing down on a substantial header, would be needed.

I believe that the only solution for framing this roof, is one using engineered trusses.

View Image

"A stripe is just as real as a dadgummed flower."

Gene Davis 1920-1985

I understand it has been years since you posted this information, but we are contemplating the same style roof and have a couple of questions. Could you not borrow from attic truss designs by building vertical knee walls on each side of the rafters? For a 26x26 space they would provide support for the first 6.5 feet in each corner. Also, if not using cathedral ceilings and just including an 8 foot ceiling could you not add the upper support similar to an attic truss. Then the remaining walls built to separate rooms could also support the load. I have attached a diagram and am curious if you have any thoughts. I apologize for a lack of technical terminology as I am not a builder and am learning enough to design the building before hiring a someone to frame it. Thanks for your time.

I built an artist's studio a while back based on a cross gable design. The gables were semetrical, and while it seems quite complicated, it is structurally simple. The roof load is entirely on the valleys. All rafter thrust at the valleys is counter acted by the opposing rafter so no collar ties are necessary. The only load at the walls is the gable itself. To counter act the valley thrust at the corners all I had to do was strap the corners. Each corner required a post an footing to carry the loads, but the straps essentially created a ring beam that handled the outward thrust. Engineering was quite simple.

Thanks for your thoughts! Nice building. Is that a skylight of sorts?

The roof was metal with matching polycarbonite panels, Inside was t-bar ceiling with plastic panels and lights above. So the light source was in the same location for both natural and artificial. Windows were minimal because my client painted with her canvases on the walls. There was an exaust fan, that if turned on with the doors closed sucked the ceiling panels out.