Type of Joint for Composite Deck Rail

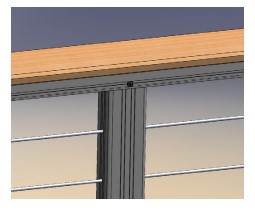

Apologize upfront, I’m a 65 year old woman trying to complete a job that a contractor didn’t finish. I have installed the RailFX 400 cable system onto the composite deck. All that is left is mounting the 20′ lengths of 1″ composite onto the top rail. This is a continuous top rail so I will need to join the straight run railing in several places. What type of joint should I use on the straight runs, I get the mitered corners. I have included a snip of the instructions, they mention a scarf joint, but don’t mention that in the same sentence as composite. Do I use a scarf joint on composite? Do you use glue, screw or let free slide for expansion? Only attaching on either side of the scarf joint. And if a scarf joint what degree cut do I make?

Replies

A scarf joint is going to tend to open up. I'd use a half lap joint.

With pvc decking or trim you need to be aware of temperatures at time of installation and even then surprises occur. Material sits all night in the cold (pretty cool) and the sun comes out and the boards used first were cold and now the next stack is warmer …..Summer install most probable will shrink in winter, and the opposite with seasons reversed.

I have used a fair amount of azek and even being careful and attentive to all the precautions and conditions there can still be shrinkage and expansion on long runs.

With a rail cap I might use like or pleasing lengths and round over the butt ends (or half laps) so it looks planned.

We camp alot now that I’m done with the trade. At one sites we arrived after a full sun day. There in the sun was an old steel picnic table frame with brand new pvc top and seats. Buckled so bad you’d have hold onto your beer or you’d lose it even if you could sit down.

The campers arrived at that site and stacked their coolers etc on it over night. Cold night, everything flattened out. Evidently they didn’t allow for the expansion when they did the change of material over the winter.

And there’s absolutely nothing wrong with a woman but way bad news for a “contractor” that didn’t finish. How do those guys continually find work?

Best of luck!

https://www.railfx.net/contact/

These folks offer contact info, you may get some helpful info from them directly.

I think I read they want joints in the cap over a post.

I would be tempted to make the joint a butt joint, and even do so at the corners.

Miters will open up, and trying to make them match perfectly may not be so easy.

One thing to consider is using a router bit that matches or is close to the profile on the ends to provide some relief at the joints..

Depending on your layout, if you know you will have some left over, make some practice parts and see how you like the looks of the joints.