Our Tranzsporter jacks are not long enough for the gable wall we want to raise, but the wall has window openings that give us an opportunity for a workaround. The framing gang consists of two.

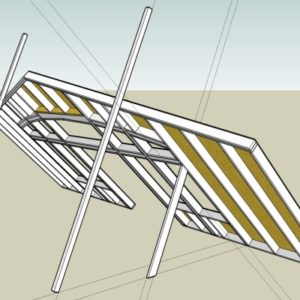

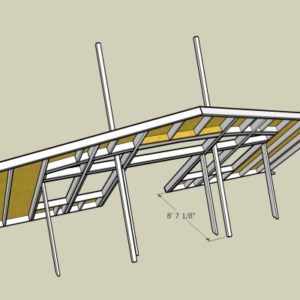

The pic “where ya gonna stand” shows what might work, provided the jack lever arm is short enough to clear inside the window as the wall raises. It isn’t.

So, we can jack the wall from its top, going part way. The pic “start jacks here” shows where we’ll set them.

We cut some 2×6 temp braces, to use when we get the wall up to about a 45 degree angle. The pic “raise to 45 . . . ” shows progress when we stop jacking and do temp braces.

With the braces now holding the wall, we disconnect the Tranzsporters, set the wall hooks where they need to go, and then reposition the jacks so they are pulling the wall up by the window headers. By the way, we’ll want to brace those headers by screwing on a long section of 2×8 to the outside of the wall, done before the raise. See the pic “takedown & reset . . . “

The pic “brace view” shows a close up view from the under side.

With the jacks reset and the wall stop-hooks set to the right location for the lift height, we cinch up the jacks so they are supporting the wall, disconnect the temps, and jack the rest of the way.

Sure, you can say, “I use my telehandler,” but we bought a Porsche instead.

And, yes, that is 24″ centering you are seeing for the wallstuds. We be buildin’ green.

Edited 7/7/2007 1:44 pm ET by Gene_Davis

Replies

I won't say it's for everyone, in fact I stop short of suggesting this to anyone not very familar with this type of rigging and the rigging equipment, but we've used multiple comalongs, 10,000 lb 2" nylon straps, load rated connections, etc. to raise walls like that when in a pinch.

Attaching the wall plate to the deck is critical so it doesn't rip free and get pulled off the deck. Simpson straps at multiple places seems to be ideal, although nylon straps also work and are easier to cut after the wall is up, but harder to secure.

The best thing we've done is attach a few long lvls to the face of the wall and let them extend out as if a counter balance of sorts. They have to be attached very well or its an easy place to have a failure. Now they can be hooked onto with comalongs and winched in, raising the wall. Both the cantalevered weight and force of the comalongs work together to bring things vertically. The lvls also prevent the wall from going too far over.

Getting a person anywhere near or under the wall while using this technique is asking for trouble and braces must be installed as the wall goes up or there is risk of deck damage if the wall comes loose.

It might be better to simply hire a better equiped framing crew to stand and temp brace the wall.

Beer was created so carpenters wouldn't rule the world.

I hear ya, Don. My idea was to in-place frame it, piece by piece, but no, it got framed on the deck, sheathed, blah-blah-blah, and now it needs to be raised.The height at the peak is just short of 15 feet. It's a heavy booger, just short of 30 feet long, and could be a bone-breaker if it came down on you.I should have noted the first post with a huge caution: "THIS IS DANGEROUS. INJURY OR DEATH MAY OCCUR."