I’m having a devil of a time trying to teach myself to MIG (GMAW) overhead. I diddled all week trying to weld some little brackets under the car frame (1/8 to 1/8″ mild steel, ground shiny), with absolutely zero success.

Tonight, I just cut off the ugly welds, brought ’em in the shop, and welded on little tabs to bolt the pieces on to the frame.

Beeyootiful welds!

So why can’t I do it overhead? I usedta’ could stick weld overhead. . .

Is wire-fed just impossible overhead? Tried either polarity, different gas flow rates, different amperages, different wire feed speed, NADA

Forrest – not a welder, either

Replies

did you try a different angle? maybe you're not holding the gun just right.

it can get out of whack fast if you don't move the whole thing sometimes

.

.

.

, wer ist jetzt der Idiot ?

<did you try a different angle>

I did. This was a "T" joint, so I was somewhat limited to what I could see around

Seemed like whatever I did, the molten metal dripped back into the cup, or hit the concrete and shot holes in my clothes.

I was wondering if I should try heavier wire? I use .025 for most everything up to 11-12 gage, and try to have no thicker parts on the car.

Forrest

I can do it, buy a thick leather welding coat, thick gloves. I like the wide glass visor, with a good lether hat. You really need to be snug in leather so you not afraid of splatter. turn the gas up a little more than usually and hang on..

<Turn up the gas>

Is that to help cool the joint, or press the droplet "up"?

Thanks

Forrest

you lose alot of gas welding overhead so increasing the pressure helps with the shielding, a guess you could call it gravity, dont know, it helps me..

Try to trigger the gun quickly, move slightly, trigger again. Kinda like you're faking a TIG look with a row of dimes look. Make sure that you move fast enough that you get good penetration into the previous puddle and the base.

Depending on the joint configuration you can make a "c" or figure 8 weave on each triggering, or just a quick spot depending on the joint.

Keith C

So, sorta "tap- tap -tap", with the idea being the droplet can cool a little between pulses?

Have to try that - gonna' make a practice jig instead of under the car, first!

Thanks -

Forrest

So, sorta "tap- tap -tap", with the idea being the droplet can cool a little between pulses?

That's how I was shown to do vertical joints if the metal wants to sag/run. Kind of like dipping the rod in when doing TIG or Gas welding- just add little dabs of metal/heat as the pool starts to cool.zak

"When we build, let us think that we build forever. Let it not be for present delight nor for present use alone." --John Ruskin

"so it goes"

You need the guy who put the fuel lines in our plant. Two black iron diesel lines running about half a mile from the powerhouse to the fire pump, through the basement ceilings of a dozen different buildings (all connected together like pop beads). Zigs and zags everywhere. All MIG (or maybe it was TIG) welded, with the neatest, smoothest joints I've ever seen.

Edited 2/10/2007 12:00 am by DanH

there are a lot of really good guys out there, its just a matter of practice. i found there is a huge jump in the learning curve when you finally get good enough in school to go out in the field and get 50 - 60 hours a week under the hood.

my first year welding i had just over 400 hours of practice in school, while working full time. i was second to the worst after the first 2 weeks, but i just kept at it, and eventually got pretty good.

i would love to be able to go back and get some other welding training, these days everything is so specialized. i would have a tough time with the TIG, and i imagine the TIG guys would take a while to get the hang of 232 fluxcore.

.

welding is knitting for men ~segundo '07

in order to weld overhead there are many variables that have to be tuned in for quality beads

the first thing you should do is practice with a similar metal, not on the car

you have to choose the correct wire to weld out of position, some wire will work and some is practically impossible, my personal favorite is lincoln NR 232 MP, also known as E71T-8. esab makes an acceptable E71T-8 as well but i prefer the lincoln wire, now this is strictly a flux core wire, no gas needed. there is also a dual shield wire in the same classification, which means that you use the gas and there is some gas from the flux in the wire.

the reason that i like the E71T-8 is because it is a high production fast freeze wire. if you are at all familiar with the "stick" electrodes, 7018 is an all position stick, as is 6010. but the 6010 is a fast freeze, great for gaps or tacks, especially out of position. now if you can imagine the best qualities of both put together and then give it a good dose of steroids you have 232. the whole thing with fast freeze is it will stick overhead. with the proper setup i can easily weld beads as big as an average finger overhead.

in the major earthquake areas 232 is all they will allow anymore because of its high performance in the "chirpy" test, and if it performs well in many applications, now again this is my favorite, the one i have the most practice with. it takes a while to get used to it, and for your application you will need to research what wire, gas, and approximate setup for volts and speed. a good rule of thmb is if it will lay down a good bead flat, it is set good for overhead as well, and if you find its falling out on you try turning down the heat and the speed just a little, and again try it flat after adjusting to make sure it is set.

Wow! Sound like you know of wherof you speak. I'll go to my supplier and get a spool of the right wire.

My welding classes were back in HS in late 70s early 80s. I was good then (no MIG then), but only recently have tried to get my hand back in, wanting to build/modify a car frame. My teacher could TIG weld Doublemint gum wrapper foil to itself (after peeling off the wax paper). Some kinda giant, yellow, high frequency machine.

Thanks again.

Forrest

wait now don't just run off all excited, i think it wise to look up what wire to get for your application, you may have the right one! what is it you have?

also let me point out the AWS website, and if i am not mistaken you can get information there about the different classifications of wire and what they are for, also i would check lincoln's website for info before i talked to the local welding supplier. some of those guys at the welding supply know their stuff, but some have never welded, ask nicely if they have ever tried it personally.

if you go during business hours and there are real welders in the supply when you are there they may offer advise as to which wire.

the welding itself is just practice, but getting the right setup for the right application is asking people that know more than me about what you are working on. i was just pointing out that with the right set up you can get huge beads to stick in the overhead position, and it is very specific.

a small wire size .025-.030 classification E71T-8 may work well for your application, but it might be better to get a similar wire classification that also uses the gas (dual shield). you need to look for something that is fast freeze for out of position, and easy to work with (user friendly).

But I am excited! I'm just that way!

Here's a pic of what I finally did - it's the piece with the cable going thru it. Took the brackets off, welded a triangle tab to each, and screwed into tapped holes in the frame.

View Image

See, the weld is purty, if I can do it on my table!

All gets taken back apart and undercoated once it's "right"

Forrest

Edited 2/10/2007 2:49 pm by McDesign

beautiful work, passes the visual inspection with flying colors

i am still curious to know what wire you are using? gas?

please share your settings, your leaving out all the good stuff!

Umm . . . let me go check

OK - the wire is SureArc S-6; 0.025 wire; 75%Ar/25% CO2; 55 Amp setting; torch polarity is red

How does all that sound? I pretty much have used that for everything; less Amps for exhaust tubing.

Forrest

torch polarity red, i assume that is positve which sounds correct. ( a few wires are negative, 3M frinstance.

75 argon also sounds good

SureArc S-6, i do not recognize that wire by brand name, is there a classification number as well? the higher numbers at the end indicate good for out of position (vertical and overhead). who makes it? hobart?esab? please don't tell me its what came in the wire feeder.

frinstance lincoln NR 232 MP is the trade name of the manufacturer, but the classification is E71T-8, and the 8 is what indicates good for out of position.

same 7018 stick if i remember correctly

Okay - I have been using what the guys at my supplier recommended for what I was doing (not overhead at that time) - worked fine.

The wire is Lincoln Electric, and does have some numbers on it - ER70S-6 in one place, and 201714 in another.

Mean anything to you?

Thanks -

Forrest

yeah thats the classification, the ER70S-6. if you got it from if different manufacturer (esab) you would identify the wire by classification to get the same product.

as i think about it hoping i am remembering correctly but not wanting to go look it up the 6 at the end is designating it as ok for out of position, but maybe not quite the best. the higher the number the better for vert and overhead.

thanks for the info, and it came out great.

That wire is a common mild steel gas shielded wire. The 6 on the end (as opposed to the 3 or 4 designation) indicates that it has more manganese and silicon in it than the others and is designed for welding on rusty metal.

The problem with that wire overhead is that it wants to form a big puddle to carry the contaminants away from the weld and is not good for the type of work you are trying to do.

You would be much better off with one of the gas shielded flux core wires or regular flux core wire for what you were trying to weld.

ok i am busted, if not the last number in the classification which one indicates suitability for out of position?

i am sorry for remembering wrong and not looking it up before posting, is that the case with all MIG wires as well?

i agree with the flux core being good for overhead for sure, but it has disagvantages too, it is awfully messy and spatters all over the place, there would be dingle berries all over the under side of McD's CRX if he used that, and didn't shield everything

I'm not sure how they classify the wires, but I do know that for stick electrodes, the second to the last number is the one that indicates the position. A "1" is the designation for all position rod.

A mild steel, all position, shielded flux core wire, such as Lincoln's Outershield 71M is a good choice for overhead welding where you want minimum splatter. It is very clean and it's easy to clean up the slag. It freezes very fast and doesn't want to run.

Trouble is, I think it only comes in .035 and larger and uses CO2 or CO2/Argon mix for shielding. This would require all kinds of adjustments to his welder.

Smaller wire such as .025 is much easier to use if you want precise welds. My best friend and I rebuild all kinds of equipment including antique cars and he has a commercial model of the car rotator in his shop. We seldom have to make a weld overhead on a car because of that rig so we use .025 gas shielded for almost everything.

I do most of my welding on heavy equipment and am not so concerned about "dingle berrys" ;)

I spent a few years rolling around under hot sparks, what specifically is your problem welding upside down?It is almost impossible to burn through when welding overhead with a stick, but a wire feed can pop through the puddle if it is too fast.My best description of the act is to melt through the metal and let the puddle be on top.Lot's of leather or Carhart's and I have to be comfortable.OTOH, I don't know that I ever had an overhead weld that looked good enough to post a picture of. :-)

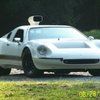

Yer doin it all wrong. You've got to build yourself a rotisserie, like I did!

View Image

View Image

View Image

SUPER easy fixing that salt rust in the floor seams now!

And yes, it was all fastened with screws.

Rebuilding my home in Cypress, CA

Also a CRX fanatic!

Man, that's super freakin' sweet!

Since all my stuff comes out the botttom (engine, trans, radiator, etc., that could be a dream!

Forrest - envious - never seen a wood one

so we finally get to see the CRX !

upside down !

way cool.

carpenter in transition

What kind of sauce goes with a CRX? If you can't get that published in FHB, you might try CT ;-)I was thinking of getting a small hydraulic lift in my garage for my Triumph.

triumph, did you say triumph? what year? does it have lucas electrics?

do you know why the british drink warm beer?

they have lucas refrigerators!

it could be worse, you could have a jaguar

I've never MIG welded but back in '52 I turned many a Mig into scrap metal with my F-86 Sabre!!!

Welcome to Breaktime

Home of

The Aristocrats

I've never MIG welded but back in '52 I turned many a Mig into scrap metal with my F-86 Sabre!!!

Come on, T- I knew you were old when I met you at Andy's but that'd make you around 70! 65 I could believe, but not 70..........

Bob

i was the youngest ever air combat ace....

did I evre tell you how I almost shot down Von richtoffen???Welcome to Breaktime

Home of

The Aristocrats

just by chance did you ever know a william/bill payne? he was one of the first to fly the f-86 ?

p

the more i weld the better i get.... that means i weld better 5 min into my work than when i first start... don't know why always been that way for me...

025 wire? .023 is more common.... i prefer nothing smaller than 030 for 1/8" stuff... 023 is mostly for sheet metal

it makes a huge difference if you push or pull the weld...ie: weld with the bead behind or in front of you.... I usually prefer to weld uphill vs down...

upside down i like to push the weld... what will really improve your welds is a really good welding helmet (auto adjust) set on the right setting.... amazing what being able to see the weld will do for you... everything else is setting the correct wire speed and heat/amps to the metal being welded...

the more you weld the more you learn your welder and will know what adjustments will do what...

I've never been a fan of flux core wire... if you have gas you should use it.... I mostly use co2 just cause when i'm welding i'll burn a bottle every 2 days... $10 for co2 vs $35 for argon mix... a little more splatter with c02 but thats what anti splatter spray is for...

p

025 wire? .023 is more common....

I have Lincoln welders. They all use the .025 size.

.... amazing what being able to see the weld will do for you... everything else is setting the correct wire speed and heat/amps to the metal being welded...

Isn't that the truth!!! .....and the older you get, the more you will appreciate one of those helmets!!!

This is why I would spend a few more dollars to get a welder that has infinitely variable wire feed speed. It's in situations like this, where you can fine tune it to get the exact performance you want.

preheat with an oxyacetylene torch, 'cause that's what you're basically doing with the MIG set up. Then you'll have much better luck doing an out of position weld.

phat

I remember back in the day, when everything was shiny new. Now, instead of being polished, it just kinda chafes.