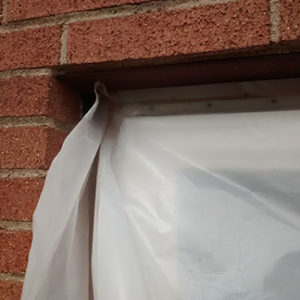

My brother has asked me for some advice on trimming out this daylight basement window. The units were installed a few months ago, but never finished. They’ve been under visqueen for a long time, and now that the rain is about to begin falling again in the Pacific NW, he’s trying to finish the job before the leaks start.

I’ve advised him that sealing with silicone along all the joints first is a good idea to stop air leaks and wind driven rain, but his main concern is the window sill below the units. Originally, there were cast concrete blocks that were installed at an angle to shed rain, but those blocks no longer exist. The top of the foundation is exposed. The lap siding behind the brickwork is also exposed with no real flashing or house wrap. Above the window is a piece of steel angle that supports the weight of the brickwork, and spans the width of the brickwork opening. This window is near ground level, and is on the west side (wet, windy) side of the house.

The attached pictures help tell the story.

Advice needed:

- What’s the best way to seal around the units, and seal the sheathing behind the brickwork?

- What material(s) should be used to build up a sill that sheds water?

- Are there any concerns about adhesive flashing (Grace) that could be incompatible with the brickwork?

- What’s the best method to cover the angle iron to give the window a finished look without causing undue water leakage concerns, as the angle iron, which has been continuously exposed can dry now, but may not dry if covered?

Our initial idea for the sill was to drill for anchor bolts in the foundation, tie a pc of rebar to the bolts, and build up a concrete sill at an angle that a non-incised pc of pressure treated lumber could then be placed, and after that, build up the finish work from there. Good idea or not?

Thanks for your help,

Jesse

Replies

The usual trim is "BRICK

The usual trim is "BRICK MOULD". I'd use PVC brick mould. I would paint the angle iron with a paint that is known to retard rust after cleaning and treating the metal properly. As for the sill, use a mortar mix, or one of the acrylic modified patching compounds that can be built up to the thickness you need. Some are for thin use only. I'm not a big fan of silicone, I'd use a polyurethane caulk for sealing.

Well, most of all you need a sill. It's hard to guess what the best way to do the sill would be since really the sill should run under the window. I guess you'll just have to butt something (probably PVC lumber) up against the bottom of the windows,caulk it, and hope for the best. To support the sill you need to build up with masonry, I suppose. I'd probably be inclined to use matching bricks or concrete bricks. But be sure to flash behind and install wicks at the bottom to let moisture out. (It's unfortunate that the whole mess is so close to ground level, but not much that can be done about that at this point.)

On the sides and top you want brick mold. Standard 2" brick mold might fit, or you might need to widen it by attaching a ripped piece of PVC lumber on the outside edge -- hard to tell from the pictures. In the middle between the windows probably another piece of PVC lumber (with brick mold on each side).

For sealing, you should first make sure the windows are thoroughly foamed in on the inside, for air sealing. Caulking on the outside should be done as the sill and brick mold are installed -- you want the caulk to be at the outermost layer. Apply caulk between brick and brick mold, and between brick mold and the nailing flange. I favor a silconized acrylic latex such as DAP Alex Plus -- properly applied it will last 20 years or more.

zip tape flashing, stone sill, and pvc

The pvc brick mould suggested is a good idea.

Further, I would flash with zip tape (there are obviously other options) around entire perimeter of framing making sure to slope the sill section in a manner to shed bulk water (as normal frame sill would be done). I woud pre-slope sill with a piece of fat mudded hardi backer before the sill flashing is installed so that it sheds. You could also mortar the angle, but you'd have let it cure before taping; hardi avoids this time delay. I would also use a chisled edge slab of limestone for the sill. To me that would be a classy way to go and look professional; particulary with the windows close to grade.

Attached is a sketch. It's quick and not to scale. Note: I don't know your existing dimensions, so brickmould pad out as shown may not be necessary.

window trim out

I don't want to seem rude, but your questions seem indicate that you are in the trades. I think you would be wise to get someone whose trade this is. There is not a lot to do and should not be all that expensive.

Not done correctly, it will cost even more to repair. Done right, sleep tight. :) Good luck.

A big thank you to everyone who responded. Very helpful information. I've installed windows before professionally, but not for very long. I've installed them in my home, but not in a brick sided house, so any extra information regarding the unique techniques is a great help.

I'll keep updating this thread as the project goes forward to finish this up. I'm looking forward to helping my brother. We're both capable and competent, but I thought I'd ask the more knowledgeable people in this field.

Obviously, the last thing either of us want is to finish the project and by force of oversight, forget an important step that proves costly to the integrity of the work.

Why didn't the window openings get fully wrapped prior to the windows being installed? Can you remove the units and do this now?

unneccessary waste of time

IMO, you wouldn't gain anything from wrapping the opening prior to setting this retro-fit window. It would be helpful to do this if you could integrate the window flashing with a continuous WRB, but since it's a retro-fit that ain't hap'nen.

What ever the answer is it won't involve any silicone. I'd be using Vycor flashing tape to cover the flanges and lap up onto the bucks then installing PVC brickmold sealed with a polyurethane sealant.