Hi all,

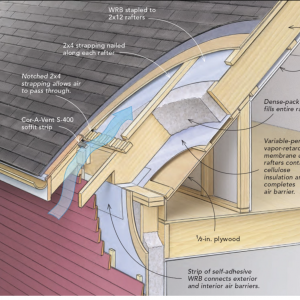

Looking at Josh Salinger’s article from a couple of years ago (https://www.finehomebuilding.com/2021/04/28/a-new-take-on-insulating-a-roof) I find that the exterior WRB is tied into the inside membrane at the top of the wall (see illustration) while the roof exterior WRB ends at the eave. The roof WRB could be extended and sealed to the wall WRB (lots of taping) but that doesn’t appear to be the case.

If the roof’s WRB is extended and sealed to the wall WRB and the membrane on the inside walls is taped to the ceiling membrane, what’s the benefit of tying the exterior WRB to the ceiling membrane?

Replies

The membrane on the bottom of the rafters is the air barrier, as is the membrane on the outside of the walls. Tying them together maintains air barrier continuity. It’s similar to what Dan Kolbert and others do with sheathing connecting from exterior of the wall to interior ceiling, just with a membrane instead. https://www.finehomebuilding.com/project-guides/insulation/a-case-for-double-stud-walls

I'm mainly concerned about the roof WRB ending at the went strip leaving a foot or so unsealed. Impact on the cellulose insulation?

“[Deleted]”

The vent strip is over the top of the wall sheathing. there would be no need to insulate the overhang, and good reason not to do so. The .pdf of the article shows photos with vertical blocking placed between rafters over the outside edge of the wall, which secures the insulation in place and keeps pests out.

What looks strange to me is how the strip of self-adhesive WRB is applied over the top plate, adheres to the WRB on the outside of the wall, and somehow adheres to the vapor control layer under the rafters.

Josh's folks must have mastered the art of trimming the tear-resistant liner to let the material adhere to the top plate, while leaving the liner intact on the free parts while the rafters are placed, and for some time before being removed to seal to the outside WRB of the wall, and the vapor control film.

Would be simpler if the wall exterior WRB is already in place when the strip over the top is placed. The liner would need to remain only on the portion on the interior side of the top plate. I wonder if they staple it to the underside of the rafters after they are secured in place, then remove the liner when placing the film over (er, under) the strip of WRB. Probably makes rafter placement a bit more interesting.

Using a ridge beam, and having the floor joists attach to the walls below the top plate likely makes this a lot more workable.

The purpose of tying the exterior weather-resistant barrier (WRB) into the inside membrane at the top of the wall is to create a continuous air and moisture barrier. This helps prevent air and moisture from infiltrating the building envelope and potentially causing issues such as mold, mildew, or rot.

Extending and sealing the roof WRB to the wall WRB would provide added protection against air and moisture infiltration, but this may not always be necessary depending on the specific building design and local building codes.

Tying the exterior WRB to the ceiling membrane provides an additional layer of protection by creating a continuous air and moisture barrier that runs from the roof to the walls, further reducing the risk of air and moisture infiltration. However, this may not be required in all building designs and is dependent on the specific building code requirements and the overall construction strategy.

In conclusion, tying the exterior WRB to the inside membrane at the top of the wall and extending and sealing the roof WRB to the wall WRB are both important measures to create a continuous air and moisture barrier and prevent infiltration. The decision to also tie the exterior WRB to the ceiling membrane depends on the specific building design, local building codes, and construction strategy.