Synopsis: Although the rim joist is frequently an afterthought once a house is built, an insulated rim joist can go a long way toward helping to reduce energy bills. Isaac Savage, president of Home Energy Partners in Asheville, N.C., details his technique for insulating a rim joist. Forgoing fiberglass batts, which can permit airflow, Isaac uses spray-foam insulation to fill all gaps, holes, and joints. The article includes a list of spray-foam sources.

As a building-performance consultant, my main goals are to improve the comfort, efficiency, durability, and healthfulness of buildings. To achieve these goals, it’s necessary to control the movement of heat, air, and moisture within and through a building envelope. Attention to insulation and air-sealing details throughout a house is critical.

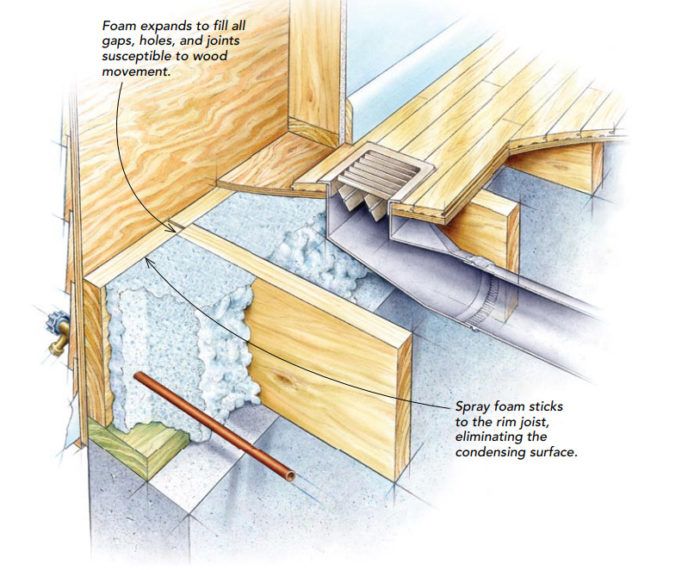

The areas most susceptible to energy loss and moisture damage are often the ones you no longer see after a home is built. The rim joist, also known as a band joist, is a perfect example. It should be insulated to achieve the same R-value as the exterior walls. All joints around the rim joist are susceptible to expansion and contraction, making them especially vulnerable to air and moisture movement. Once the drywall is installed, the rim joist is rarely thought about again. But improper insulating and sealing in this area can lead to comfort complaints, high energy bills, air quality issues, and moisture damage.

In the past, few options have been available for insulating rim joists, but with the increased awareness of building science, manufacturers are developing innovative solutions to insulate this area properly. Relatively new to the market, two-component spray-foam kits offer a quick, effective solution to tricky insulating problems. The kits consist of two liquid chemicals that mix together in the tip of a gun, then expand once they hit the surface. The foam is highly adhesive, so it sticks and stays in place as it expands to fill gaps. Once cured, the foam provides an effective air seal as well as insulation.

Fiberglass doesn’t stop airflow

Stuffing fiberglass batts between floor joists is a common method of insulating the rim joist in many homes, but it’s a severely flawed technique. Fiberglass works best in an enclosed space where it can trap air (between drywall and the exterior sheathing of a stud wall, for example). The insulation cannot perform at its full-rated R-value because air and moisture can move freely in and out of the building through wall penetrations and wood joints, eventually making their way into conditioned space through areas like floor registers. Not only does air move freely around the batts, but because the insulation is not enclosed, it moves freely through the fiberglass as well.

Spray foam does well

A two-component spray-foam kit is insulation and air barrier, making it the fastest, most efficient way to seal the rim joist. When sprayed between floor joists, the mixture sticks to the surrounding surfaces. The foam expands to fill holes made by wall and floor penetrations, and it seals wood joints, stopping air and water vapor from entering or escaping. Once the foam expands fully, it insulates the cavity as well. Because the foam doesn’t allow air to move through it (which diminishes R-value), it always performs at its full-rated R-value.

For more diagrams and details on the best way to insulate a rim joist, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Respirator Mask

Staple Gun

Caulking Gun