How to Seal 4 Hidden Air Leaks in Your House

In this "Energy Smart Details" article, Martin Holladay describes how to seal leaks in fireplaces, floors, walls, chases, and soffits.

A 1⁄8-in. crack doesn’t seem like much to worry about, but a 1⁄8-in. crack that runs the length of your house amounts to a square hole 8 in. on a side—a big-enough hole to toss a cat through. Because it is a crack, you can seal it with caulk, but not all holes in the building envelope are cracks that can be sealed with a tube of caulk. Some of them really are big enough to toss a cat through, and they need to be sealed with sheet goods such as drywall, rigid foam, or plywood.

Some common gaps and holes are listed in the Energy Star Thermal Bypass Checklist. Among the most common holes found in poorly sealed houses are holes near soffits, chases, and bathtubs. Green Building Advisor has a collection of 56 detail drawings that pertain to the Energy Star checklist. These drawings come from that collection.

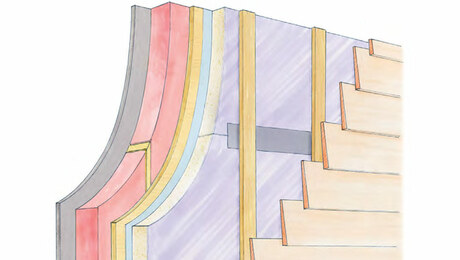

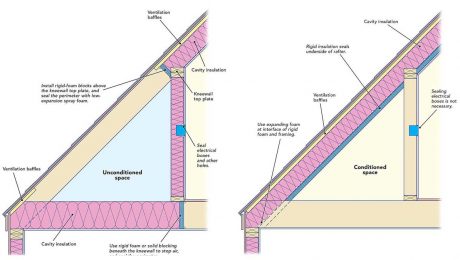

Chases and soffits are raceways for air leaks

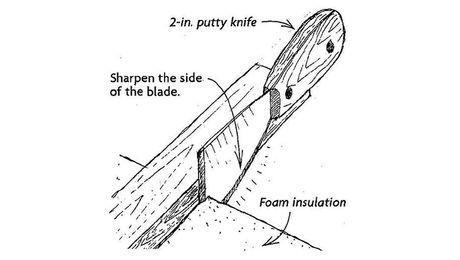

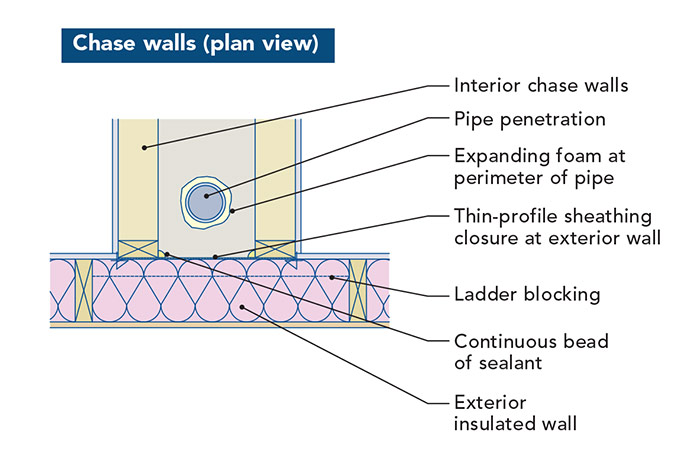

Older houses often have several big holes in the attic floor. Many are around open chases for ducts, electrical cables, or flues, often running unimpeded from the basement to the attic. When installing plumbing chases in new houses, install air-barrier sheathing first, and seal the gaps between intersecting walls with caulk. As the framing shrinks, these gaps become large. The top of an open plumbing chase in an existing house can be sealed with a variety of sheathing materials as long as seams and edges are sealed with caulk or tape.

If any chases for plumbing pipes, ducts, or flues originate in the basement, be sure to seal the chases at the bottom with the same techniques you used to seal the chases in the attic.

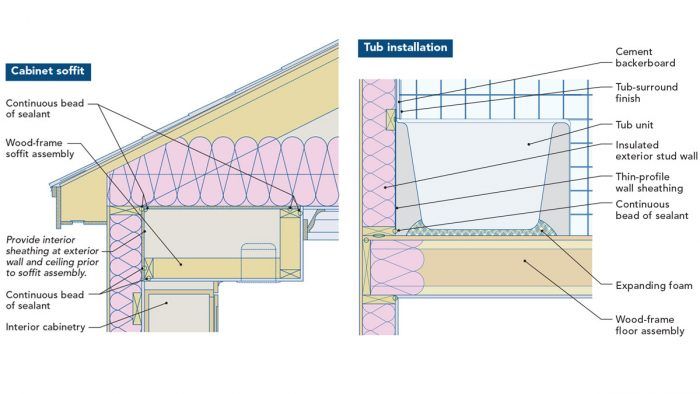

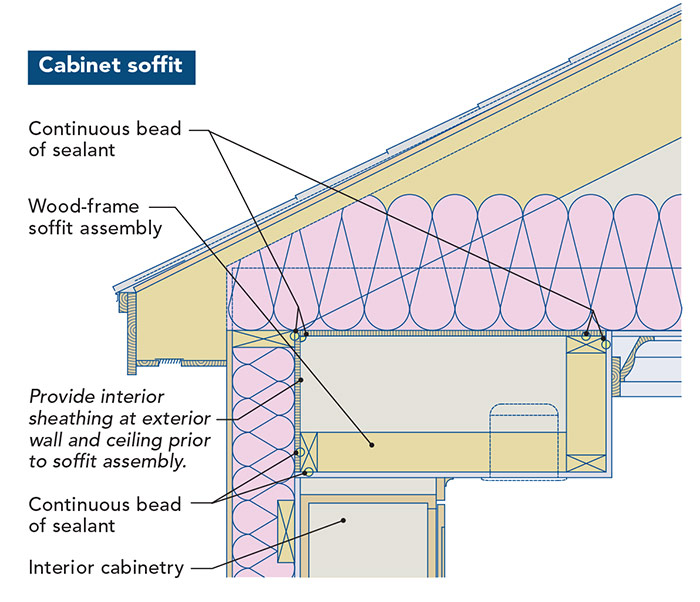

While you’re in the attic, check for any unsealed kitchen soffits. Such soffits are often built above a row of wall cabinets. In new construction, the ceiling drywall should be installed and taped before the soffit is framed. The first clue to a leaky soffit is often a piece of discolored fiberglass insulation. The discoloration is caused by escaping air that has carried dust upward, often for years.

In many existing houses, the sides and top of kitchen soffits are open to the framing cavities. In this case, you can install the necessary pieces of air-barrier sheathing from above. Don’t forget to seal the perimeter of the sheathing and any seams with durable tape, caulk, or spray foam. Once the soffit is airtight, don’t forget to replace the insulation.

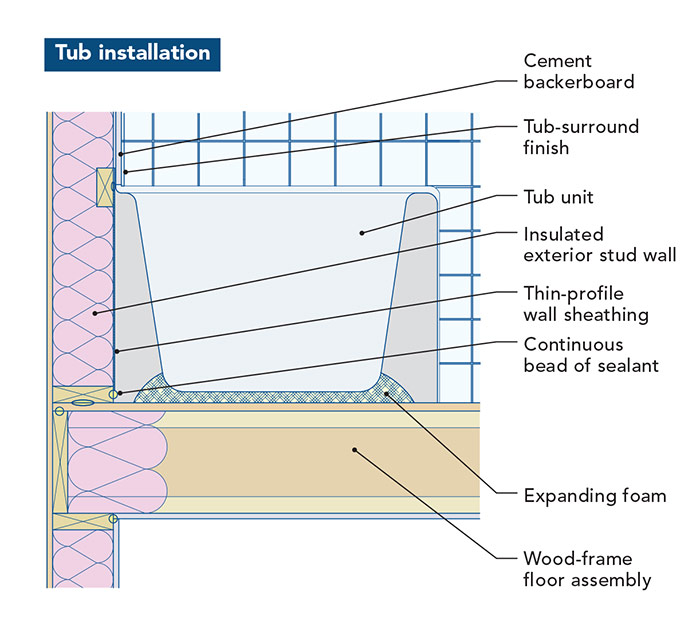

Tubs hide big holes in floors and walls

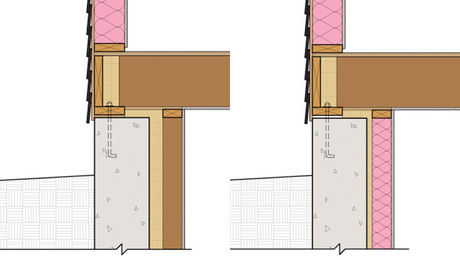

When you’re installing a fiberglass tub/shower unit against an exterior wall, it’s essential to insulate and air-seal the wall before installing the tub. On new-construction jobs, remember to install a durable air-barrier material (for example, Thermo-ply sheathing) to cover the insulation.

In an existing house where builders omitted the insulation and the air barrier behind the tub, repairs are difficult. One solution (not the cheapest) is to remove some of the siding and sheathing so that spray-foam insulation can be installed from the outside. A better bang for the buck may be to address the problem as part of a larger bathroom remodel. If you’re contemplating a bathroom upgrade, it may be cheaper to demolish the tub/shower unit and seal the wall properly from the interior.

If your house has an unconditioned basement—in other words, if the basement ceiling is insulated—be sure to pull that insulation aside and check for air leaks under any first-floor bathtubs or showers. Plumbers typically cut out a big piece of the subfloor to accommodate drain lines and traps, but rarely repair the ruptured air barrier. If these cutouts are not sealed, your floor has a huge hole.

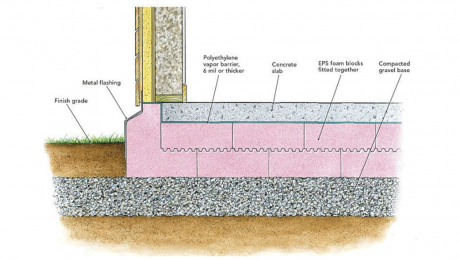

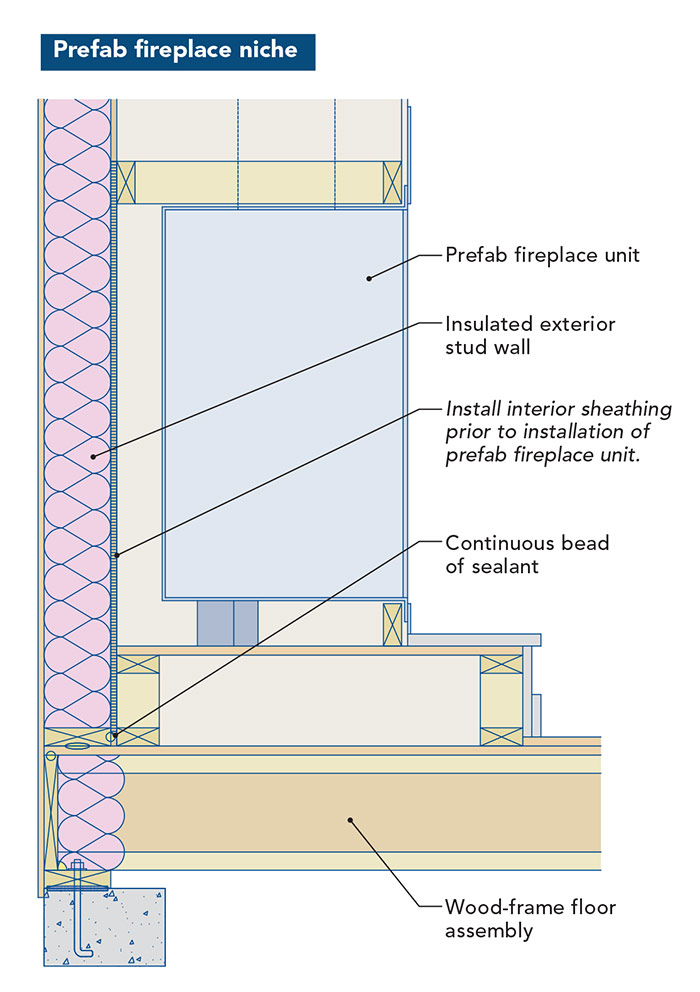

Keep fireplace heat inside

Prefabricated metal fireplaces, whether wood-burning or gas-burning, are usually installed in a niche framed into an exterior wall. Unfortunately, many of these fireplace niches are poorly sealed against air leaks.

The best opportunity to prevent such leaks is before the fireplace is installed. After the niche is carefully insulated, the insulation should be covered with a durable, rigid air-barrier material, such as Thermo-ply sheathing, drywall, sheet metal, or OSB. All gaps and seams should be sealed with caulk, spray foam, or contractors’ tape. Where the chimney penetrates the niche ceiling, seal gaps with metal flashing and high-temperature silicone caulk.

To repair air-barrier defects behind an existing metal fireplace, it may be necessary to remove sections of siding and sheathing to provide access for the installation of spray polyurethane foam.

Drawings: Steve Baczek, Architect

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Foam Gun

Great Stuff Foam Cleaner

Nitrile Work Gloves