Q:

Our company is having difficulty putting up dropped ceilings efficiently. Actually, boxing in the ductwork is what slows us down. How can we be more efficient?

Jeffrey Nixon, West Chester, PA

A:

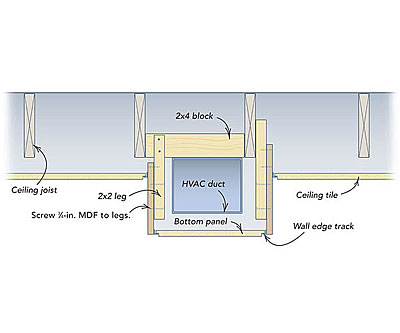

Contributing editor Mike Guertin replies: I presume the difficulty you are having is wrapping the vertical sides of the box. The simplest way I’ve found to tackle verticals is to use 3/4-in. medium-density fiberboard (MDF) fastened to solid framing.

Rip the MDF a couple of inches wider than the difference between the main ceiling and soffit levels. Screw 2×2 legs on the inside of the MDF so that you can hang it from the ceiling joists. You may have to add cross blocking between joists for intermediate attachment, but you need only one leg every 16 in. to 24 in. Keep the legs at least 2 in. up from the bottom edge of the MDF so that it doesn’t interfere with inserting the soffit panels. Adjust the bottom edge of the MDF side pieces depending on the level of the ceiling.

Mount the drop-ceiling wall edge along the bottom inside of the MDF and then along the top outside to match the main ceiling.

The solid sides stabilize the soffit and ceiling, and they resist bumps better than metal track and acoustical panels.

As an alternative to MDF, you could consider using veneer plywood with a clear or stained finish for the sides of the soffits to accent the change in ceiling height.