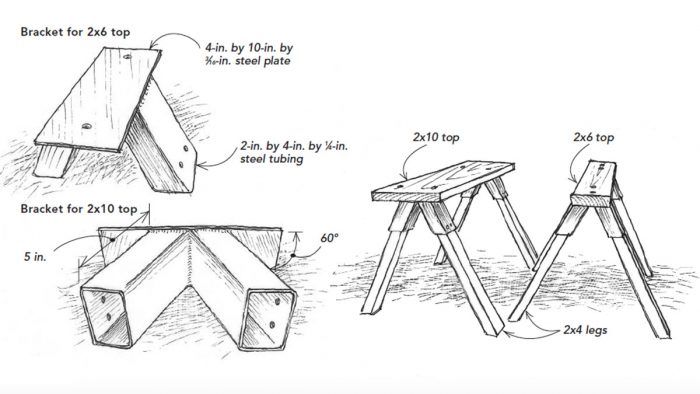

Plenty of commercially available sawhorse brackets are on the market, but I’ve found that the ones I weld up for myself suit my needs better than any I have seen. As shown in the drawings, the leg holders are made of 1/4-in.-thick 2×4 rectangular-section steel tubing. Because this stock is 2×4 outside dimensions, a wooden 2×4 slips inside nicely.

I use a 14-in. cutoff saw with a metal-cutting blade to make the parts. The leg holders are 5 in. long and have 60° cuts on their ends. At their tops, they are welded to 3/16-in.-thick bars of steel that are 4 in. wide by 10 in. long. (I chose 4-in.-wide stock because it also cuts easily on the cutoff saw.)

Next, I drill two 1/4-in. screw holes in the leg holders and a 3/8-in. bolt hole near each end of the bars. The leg holders then are welded to the flat bars. You’ll notice in the drawings that I oriented the flat bars two different ways to make two different kinds of horse: one for a 2×6 top and one for a 2×10 top. I recessed the carriage bolts securing the 2x tops so that shallow sawcuts won’t hit the bolt heads.

These horses are rock solid, they stack nicely, and they are easy to disassemble.

—Lary Shaffer, Scarborough, ME

Click here to enlarge the illustration.

Edited and illustrated by Charles Miller

From Fine Homebuilding #165

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

8067 All-Weather Flashing Tape

Handy Heat Gun