Issue 132

Features

-

Ensuring the Durability of Energy-Efficient Houses

Why are so many of today's homes plagued by rot, mildew and stale air, and what can we do about it?

-

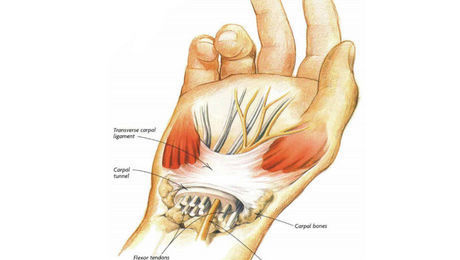

Arm and Hand Pain on the Job Site

A doctor's take on wrist, elbow and shoulder troubles common to builders.

-

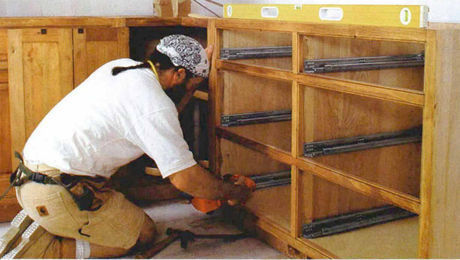

Installing Kitchen Cabinets

Careful planning and knowing exactly where the framing is help factory-made cabinets go in quickly and easily for a custom look with no nasty surprises.

-

Building a House of Insulated Concrete Block

Dry-laid walls reinforced with steel and filled with concrete make a weathertight, bugproof house.

-

A Carpenter's Lumber Rack

A two-level welded-steel rack boosts even a small truck's carrying capacity and pops out easily when you don't need it.

-

Building a Grand Veranda

A New Jersey design/build team recreates a large, comfortable porch with 19th-century details built to last into the 21st century and beyond.

Article

-

Powder-Actuated Tools

Powder-Actuated ToolsAvailable as single-shot, semiautomatic or full automatic, these low-velocity tools are the ones carpenters choose when driving fasteners into concrete or steel.

-

Choosing Materials for Exterior Decks

Choosing Materials for Exterior DecksFrom tropical hardwoods to man-made plastic composites, the choices are more varied than ever.

-

A Simple Approach to Frame-and-Panel Trim

A Simple Approach to Frame-and-Panel TrimAssemble the frames with pocket screws and trim plywood panels with molding for a traditional look.

-

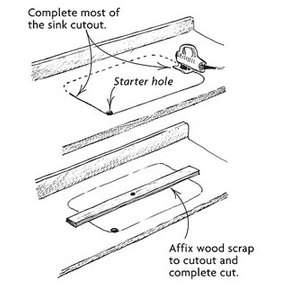

Finishing Basements

Finishing BasementsDespite the obstacles, converting that dark, scary place into comfortable living space is much cheaper than adding on.

Letters

Great Moments

More? View Past IssuesAsk the Experts

-

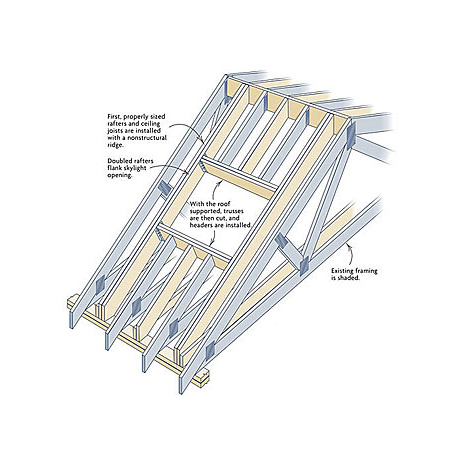

Retrofitting Skylights in a Truss Roof

Retrofitting Skylights in a Truss Roof -

Moisture in a concrete-block crawlspace

-

Lightening darkened cedar

Readers Tips

Fine Homebuilding Magazine

- Home Group

- Antique Trader

- Arts & Crafts Homes

- Bank Note Reporter

- Cabin Life

- Cuisine at Home

- Fine Gardening

- Fine Woodworking

- Green Building Advisor

- Garden Gate

- Horticulture

- Keep Craft Alive

- Log Home Living

- Military Trader/Vehicles

- Numismatic News

- Numismaster

- Old Cars Weekly

- Old House Journal

- Period Homes

- Popular Woodworking

- Script

- ShopNotes

- Sports Collectors Digest

- Threads

- Timber Home Living

- Traditional Building

- Woodsmith

- World Coin News

- Writer's Digest