Video Vault: Clearing Up the Confusion on Drill/Driver Settings

The settings that will help you get more out of your tool.

Though a drill/driver is such a ubiquitous tool, it’s shocking how many people have no idea how to properly use the clutch and speed settings. Most people just set the speed to “2” (sometimes labeled “high”), and max out the clutch, never to touch the settings again. In this gem from the Fine Homebuilding Video Vault, Justin Fink sheds some light on the settings that many people ignore, hopefully helping you to get more out of your tool.

View Comments

videos very informative

Torque. More torque, less torque, etc.

I "clutch by ear". I know how to set it, but it's usually too tedious.

How many find that these clutches are effective? Yes, I know, they designed them, so they must be a good idea. Or, at least, nobody has come up with anything better so far.

I do find the clutch useful when going into a very consistent material, not usually wood. More helpful for low torque needs like driving machine screws into threads or screwing into plastic, etc.

The impact drivers have changed the game for high torque driving anyway.

I always set the clutch at the lowest setting that can do the job.

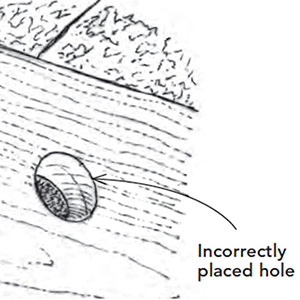

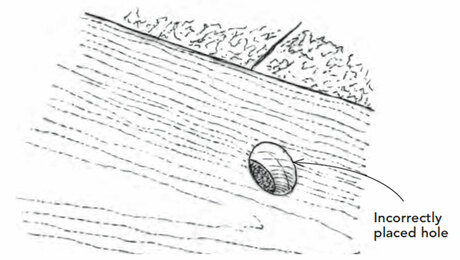

This eliminates over-driving the screw into the material, having the driver slip in the screw head (a big problem with Phillips), or stripping out the hole.

Those clutches used to work pretty poorly. They work better on newer models. Things improve. But I agree with seaweedsl that wood, especially softwood, is too inconsistent to use them. If you really are using the drill in low gear, you should be able to clutch by ear, feel, or sight. With softwoods you might need to use all three senses.

I fell in love (well, not quite) with my impact driver the moment I first used it. It is lightweight, can drive anything, and can drill holes in tight spaces. They are awesome for driving those Simpson hanger screws. But after a few years I got tired of the noise and of stripping out screw heads if I wasn't really careful. In remodeling you can't always use a nail gun if it might knock something off of the shelves on the other side of the wall. An impact driver can have a similar effect, jiggling stuff all over.

You can alleviate the stripping by using torx drive or similar screws, but you can't always get them readily in the sizes you need. You can't do anything about the noise or vibration. After a while I started to learn when and where the impact driver would be best and when/where to use the drill.