How Do I Splice a Deck Beam in the Middle of a Post?

Breaktime contributor ‘Pizza’ has everything laid out except for this last detail.

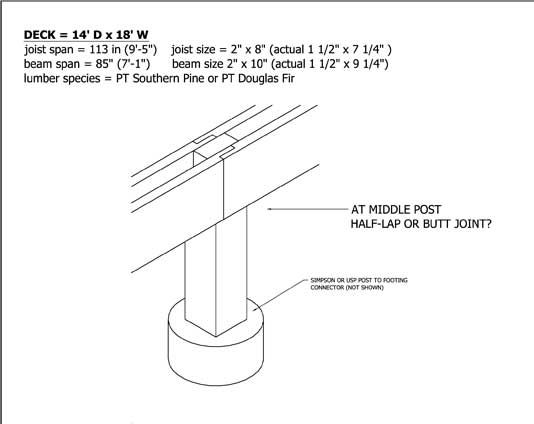

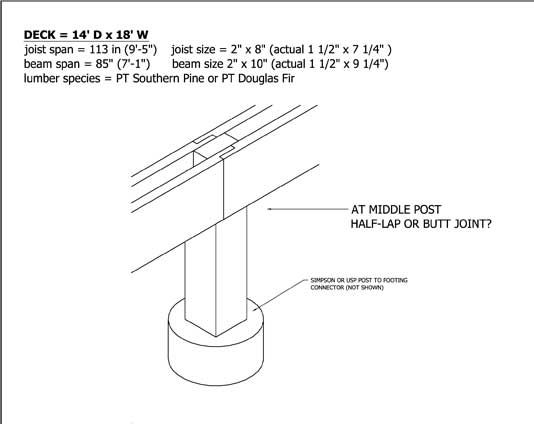

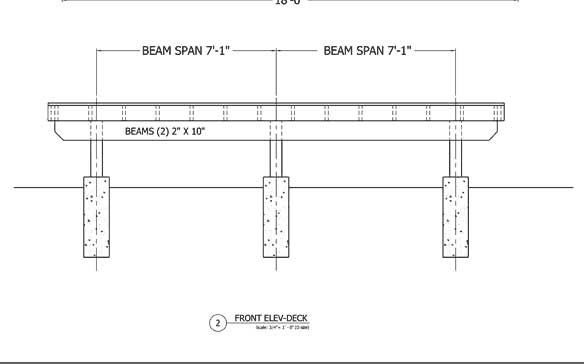

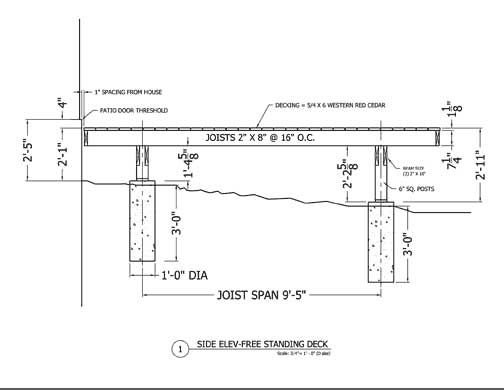

He plans to notch the 6×6 posts to accept the beams, which would transfer the vertical loads to the posts rather than to a bolted connection.

“How do I splice the beams at that middle post?” he wonders. “Is a butt joint there OK or is a half-lap type joint better.”

Questions about structure and weather resistance

“The half lap joint is a waste of time and opens up the interior of your treated wood-little or no treatment that deep,” Calvin tells Pizza. “You should treat all cuts and/or wrap-cover-protect with a product like Vycor, a peel and stick membrane that seals around nails/screws/and bolts (also gums up your bit for the bolt holes).”

Notching the 6×6 post will pose the same problem by exposing the unprotected center of the timber to moisture. “Seal those cuts and maybe cover the top with some of that Vycor so water doesn’t seep in there and fester,” Calvin adds.

K1c, however, wonders whether there are larger issues at stake–what kind of structural tradeoffs will Pizza see by breaking the beam at mid-span. And why notch the post all? he adds. Wouldn’t it be simpler to use a connector?

“I am not sure about this but you should refer to town inspector to see if your design for the mid beam would be a true beam,” he says. “Someone in this site may correct me. Your present beam is 2 single pieces close together, but not nailed together. I am not sure if this would act as one beam. ”

DanH says it doesn’t matter. “Except for the possibility of rolling (or buckling, if made exceptionally thin), it makes no difference,” he writes. “Beam strength is directly proportional to width.”

The voice of experience

Ah, but it does matter, says billg71. The Forest Products Service manual on wood decks is crystal clear on the subject of beams:

“A multiple ply beam must be nail laminated to use their span tables,” he says. “Their nailing pattern is 3 at the end and staggered top and bottom 6-in. on-center with fasteners long enough to fully penetrate two members.”

Pizza’s plans call for pairs of 2x10s serving as beams. But they’re not “nail laminated” and in fact are separated by a gap. Although that might not make a huge difference, the potential is there for problems because the 2x10s might end up carrying unequal amounts of weight.

“I’ve made a lot of money fixing decks built like this,” billg71 posts. ” 🙂 I love them! Just so you know, the fix involves jacking the beam members and laminating both sides with identical or a size larger material. An alternative is to jack the beams and rip a bunch of blocks for fillers, hoping the beams aren’t permanently deformed…nail it all together and pray it holds for the year’s warranty. I prefer not to do that, it doesn’t go with my business model.”

And why the cantilever, anyway?

More to the point, billg71 says, what’s the deal with the cantilever on each side of the deck?

That approach, he says, will add labor and materials to the job. “Why not bolt to the house and eliminate the inner beam along with its post and footers,” he asks. “A 2×8 is bouncy at anything over 8 ft. I’ll run 2x10s up to 12 ft. or so and then go to 2x12s.”

“As a general rule I avoid cantilevers until spans get extreme,” he says. “In most situations (at least in my area), decks get bolted to the band or the foundation walls. Cantilevering a beam adds additional load on that beam (the total of the cantilever and 1/2 the span to the house) for no real benefit.”

DanH, in defense of the cantilever approach, says with properly spaced supports, a cantilever has less deflection and less bounce than the equivalent structure with end supports. In addition, he says, some inspectors don’t like to see the deck bearing on the house.

“Ledger connections too often fail catatrophically, ” DanH says, “while beam-on-post construction rarely does.”

And, says Pizza, there are some pretty good reasons for the cantilever design.

One, he doesn’t want to punch any more holes in the stucco exterior of the house, which is already showing evidence of hidden moisture problems around an old slider.

Second, Pizza says, building codes now require decks to be fastened directly to the rim joist, not through a layer of stucco. That means some of the stucco would have to be removed before a ledger could e added.

Finally, he doesn’t trust caulks and sealants to keep water out of the ledger/house connection.

“It’s been my experience that no matter how good they say the sealants, flashings, flex wraps, etc. are they all eventually fail so caulking any holes I’ve made thru the house will just eventually cause rot and invite more insects inside,” he says.

Is the framing beefy enough?

Given these circumstances, billg71 sees the logic of Pizza’s cantilever design. But he doubts the framing Pizza has specified will be stiff enough.

“You could use the cantilever design you’ve drawn and just sub 2x12s for the beams (laminate them and attach with a bracket) and 2x10s for joists, billg71 says, “It might come out a little cheaper than clear-spanning 14 ft. with 2x12s and would be even stiffer.

“Aesthetically, it’d probably be a little easier on the eye with the posts not so ‘in-your-face.’ And it would be a stout SOB. You could throw a block party on it and it wouldn’t notice.”

Don’t forget, he says, spans allowed by code are only minimums.

Pizza apparently decides to keep the cantilever design, but takes billg71’s advice on the framing material. “Thanks Bill,” he writes. “I’m going to re-design this deck to be less bouncy as you suspect it will be. Didn’t know that those tables were minimum.”

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

8067 All-Weather Flashing Tape

Reliable Crimp Connectors

View Comments

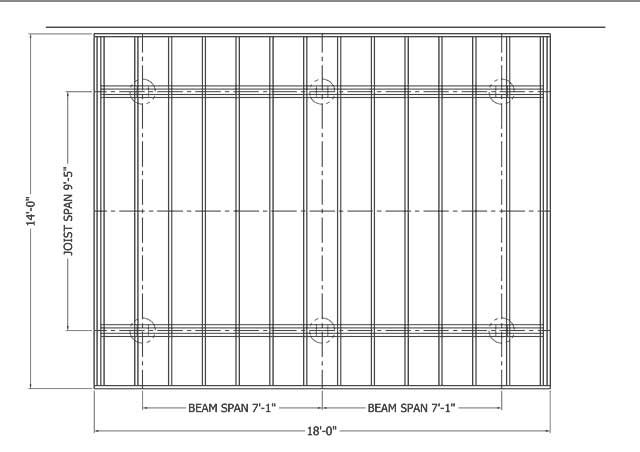

1) As presented the plan view of the joists is rotated 90 degrees relative to the elevation drawing.

2)There is NO diagonal bracing shown. Remember "Country Music can Kill You" actually line dancing with 15 to 20 people all going the same direction and suddenly stopping at the same time will topple inadequately braced decks.

3)For the beam posts take a good piece of 2x10 36 inches long, under cut it at a 45 degree angle. Now you've got a double tapered piece 36" long on top, 18" long on bottom edge.

Put it between the two 2x10s centered over the post. Clamp it temporarily while you cut 2 45 degree diagonals out of 2x8 full cut under the 2x10s. Now nail 'em up. It's not going anywhere. The un-notched post gets a galvanized top cap.

4)This beam post joint will decrease deflections 50% compared to 'simple span' beams.