How to Sharpen A Chisel With Diamond Hones and a Honing Guide

Fine Homebuilding editor Patrick McCombe shows step-by-step how to get your woodworking tools super sharp.

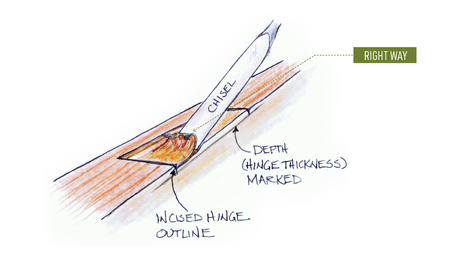

Today we’re going to talk about sharpening your chisels. Getting a good edge is really about the back of the chisel, the flat plane on the bevel, and where they intersect. I’m using DMT’s 3-piece diamond whetstone set and the Veritas Mk.II honing guide to do the job.

Flattening the back

On new chisels, you want to flatten about an inch up the back. If you sharpen beyond that point as your chisel wears, you will need to re-flatten it. I’m just going to do the lower part here. That’s simply a matter of wetting the diamond abrasive and holding the chisel on the flat. I like to use three fingers, and just run it back and forth over the abrasive. Work through the various grits of abrasive, and keep the stones wet. As you’re sharpening the chisel, you will notice this black slurry developing in the water. That’s just metal particles being carried away that would otherwise clog the abrasive. Once you get to the green diamond plate, you will notice that the back of the chisel gets really reflective.

Setting up the honing guide

Once we’re done flattening, we’re going to put the chisel in this great honing guide from Veritas. What I like about this product compared to other honing guides is the wide roller on the back that gives you extra stability. The first thing you want to do is make sure your chisel is in the honing guide properly. There are marks for various chisel widths; ours is a one inch chisel, so I’ll set the mark to one and tighten down the thumb screw. Most chisels are sharpened to a 25-degree bevel angle, so line up the tip with the 25 mark, and then tighten down the screws that secure the chisel. Once you’re sure the chisel is set in the jig, you can remove the registration guide.

Using the Diamond Stones

I like these diamond plates from DMT because they have a great, long-lasting abrasive. I start with the black grit, which is equivalent to about a 220 grit sandpaper. With the roller of the honing guide resting firmly on the diamond plate, we’re just going to run the bevel of the chisel back and forth until we have a uniform striated appearance, and all the chips and nicks are gone. If you have a really beat up chisel, this could take a while. In some cases it might make sense to use a grinding wheel and plenty of water to get large nicks out before you start with the diamond plates. This chisel took about five minutes to remove the nick on the black diamond stone. Now, we’re ready to move on to the next finest abrasive.

Flip the stone over to the blue side, which is equivalent to about a 325 grit paper. It’s important to make sure you use all of the stone by moving the chisel around. Occasionally I swap it end-for-end. That just prolongs the abrasive so you’re not wearing it out on one portion of the stone. These things are expensive, each one is about $60, so you will want to get the full life out of them. But, what’s great is that they’re very portable, very rugged, and they last a long time.

Once you notice the stone getting a little bit of a polish, move on to the red abrasive, which is equivalent to about a 600 grit paper. You will notice it gets a little more polished with every step. Next we’ll move on to the green abrasive, which is equivalent to about a 1200 grit.

It’s really tempting to break off the burr that develops on the edge of the chisel, but don’t do it; you will ruin the edge. What you need to do is move the stone to the edge of the work surface so the guide can overhang, and just gently run the back of the chisel over the diamond plate, side-to-side, being sure to keep the chisel flat against the plate. You should find that working through all of the diamond plates produces an edge that is plenty fine for most carpentry work.

Read the companion article from our latest issue: