As my crew and I took on more complex framing projects, I found the roof framing was bogging us down. Walls and ceilings would go up quickly, then things would grind to slow-mo at the complicated cut-up roof. I began to focus on minimizing roof framing time – a challenge on the complex multi-hipped roofs we were building.

After a lot of frustration, and a lot of analysis, I resolved to: A) pre-cut the roof in its entirety; and B) begin cutting the roof on day one. The layout lines were snapped, then measurements were taken for cutting the roof. While the rest of the crew framed the house, I cut the roof.

More than one naysayer dropped by to question my methodology, and my sanity! I recall lines like “putting the cart before the horse”, and “why are you cutting a roof when you don’t have a house yet?” Despite dire predictions to the contrary, I knew that as long as my crew built the house as it was snapped on the slab, my roof would fit.

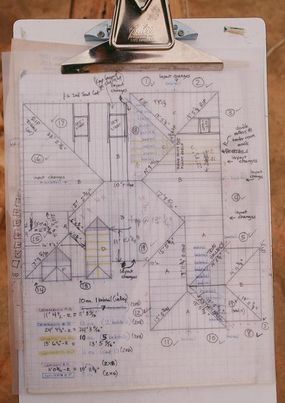

The entire roof was mapped out on a piece of graph paper, which became my grocery list for cutting the whole package. In a sense, this is similar to what a truss manufacturer does – based on the blueprint dimensions, he builds the roof’s composite parts. Once cut, each jack rafter had starter nails placed at the top, which were used to hang the shorter ones from the top plate, and made nailing in place quick and easy. The rafters were stacked neatly, and marked for location. Each hip was divided into “quadrants”, meaning the set of jack rafters up one side of the hip.

One important key to my system was that layout was pulled in from each corner (not from the center out), so the jack rafters always followed a tidy – and identical – layout at the hip, and any layout adjustments needed were made somewhere in the middle of the wall. By doing this, the jack rafters could be figured and cut from day one – all that was needed was the roof pitch and the rafter spacing. Rafter and joist placement was critical, so layout was marked carefully on the top plate using the roof diagram.

The defining members – the hips, valleys, and ridges – went up first (with a few commons to hold the ridge in place). Once the framework was up, and checked visually to make sure it all planed in properly, the “fill” began, meaning jack and common rafters.

Doing it this way forced me to take extra care, and a little extra time, in figuring and measuring. I couldn’t cut a piece then put it in place to see if it fit – it just had to be right the first time. My tactic paid off in spades, because while figuring and cutting was a one-man job, the whole crew was involved in stacking the roof.

The actual “stack” portion of this cut-and-stack went quickly – the bulk of the roof was up in a day. Pre-cutting really minimized the stand-around time that used to occur while I’d scratch my head and try to figure the tricky cuts as the roof was going up. The crew enjoyed the project more, and the bottom line got healthier, which means I enjoyed the project more, too. And the client? – well, we all know, to the client, faster is better.

The roof pitch on this particular house was 5:12, with a 24” overhang, square-cut fascia, and 24” o.c. layout. The house design, 2300 sq. ft. not including garage and patio, was from a blueprint given us by Metco homes, the builder.

View Comments

OOPS!

I tried to delete a picture, in order to add a picture of the completed roof - because I finally took the time to read the rules, hahaha - and I inadvertently deleted the whole thing! - in case you're wondering why here it is again!

Sometimes this gallery can be a tad touchy to negotiate!

Its pretty tough to tell a story in 5 small photos. If you'd like to see more and larger photos, go to:

http://eyemagination.smugmug.com/gallery/9191786_rXjWH#613456430_sxbd3

There are some duplicates in the gallery, when I get time I'll go through and organize the photos, and delete the duplicates.

Huck

Nice work. You really took a big risk on that one. But looks like it paid off.

BTW. What year did you do that roof? And how many framers are on your payroll?

Thanks Artisan77, appreciate the compliment. Not too risky - just measure twice, cut once! House was built in '91, crew was 4 full time & 2 part time, (everyone showed up for stack day), plus me. Email me [email protected], be happy to discuss the project. Also had a thread on Fine Homebuilding's BreakTime board awhile back.

Huck, that's a great accomplishment. I usually cut ridges, hips, valleys and a few commons to pin the ridge/ridges, then cut and fill in jacks in sections. Awesome show of confidence.

Thanks loneframer, but its really not that different from what you do. Just commons and jacks, that's the only difference.

You said you cut a few commons to get the ridges up - so go ahead and cut the rest. And since I pulled layout from the corner in, with 2' o.c. layout, and 5:12 pitch, the jack rafters will always be the same, every hip, every corner, every roof. No risk, I know the measurements are going to work, like they always do.

The first time you pre-cut the entire roof, it feels like jumping off the high-dive for the first time. Then its just like, Well, if I'm careful with my math and my measurements, why wouldn't it work?

And trust me, your crew will love it. My guys took a noticeable jump in pride when we started doing it this way. Instead of dreading the roof, they couldn't wait to get to it. Then they'd brag how much more roof they put up in a day than the other crews. Tim Uhler, a framer who writes a lot for JLC, does it similar, and says the same. His crew loves it. It's like "our system is better than their system".

Hey FHB, got my great new nailgun, thanks a million for running the contest! - Huck

Awesome job! I've always contended that cutting a roof like this would work, but most folks just don't have the confidence in the tolerances of their framing to attempt it. By the was, do you not ever cut normal birdsmouths? And if not, why not?