Laying Out Deck Joists

Deck builder Scott Grice shows how to pull and mark an initial layout and square the assembly–and then how to pull secondary layouts.

Once the beams are installed and either temporarily or permanently braced, it’s time to install the joists. Installing the joists involves pulling an initial layout of their locations and marking the house ledger, rolling the lumber into place, and installing rim joists. However, these tasks are not discrete. Often there will be a little back and forth among them. For example, it’s easier to register secondary layouts off of joists that have already been installed rather than doing the entire layout before installing any joists.

In this section, we’ll discuss how to pull an initial layout and square the assembly. Then you’ll learn different ways to pull secondary layouts, some of which involve joists that have already been installed. We’ll cover installing, or rolling, joists in the next section.

Most commonly, joist spacing is 16 in. o.c., but it can vary depending on the type of decking. Some synthetic decking requires joist spacing at 12 in.; and if the deck is going to carry a heavy load, such as a hot tub, the joist spacing will often be reduced even more. For the deck shown here, we used standard 16-in.-o.c. joist spacing.

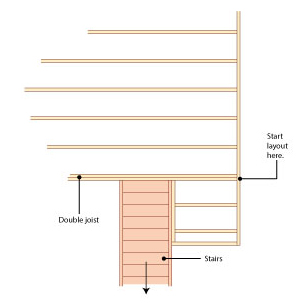

Where to Start Joist Layout

Start the layout from the logical spot, which is not necessarily the deck’s edge. Here, starting the layout at the double joist that acts as the header for the stair stringers makes much more sense than starting layout from the edge of the deck.

START THE LAYOUT FROM A LOGICAL POINT

The easiest way to pull layout is simply to hook the tape on the end of the ledger board and mark a crow’s foot every 16 in. (see photos below). On this deck, we wanted the layout to begin from the outside of the rim joist that hadn’t been installed yet. We could have stopped what we were doing to install the rim joist before pulling layout, but instead we dropped (or burned) 1-1/2 in. from the layout so that every joist was 16-in. o.c. When marking the joist location, indicate with an X which side of the crow’s foot to locate the joist. It’s also a good idea to draw a vertical line to indicate the edge of the joist. This makes it easy to install the joist by aligning the joist face to the line.

Install the rim joist to the end of the ledger with through screws. There are a couple of things to note about installing the rim joist. First, as mentioned, you can install the rim joist before pulling layout and simply hook your tape to it instead of burning 1-1/2 in. to get all the joists 16 in. o.c. Second, installing the rim joist to the end of the ledger, as seen here, has the advantage that it can be secured with through screws instead of hardware. If the rim joist butts to a full-length ledger, then corner-attachment hardware is required. Once the rim joist is secured to the ledger, use the 3-4-5 method to align it at 90° to the house.

1. Hook the tape measure on the end of the ledger board and mark each joist on the layout.

2. Adjust the layout so that all the joists are aligned on center in reference to the end joist.

3. Mark the side of the crow’s foot that the joist will land on to avoid any confusion.

4. Mark a plumb line to align the joist to when installing the joists.

5. Install the rim joist to the end of the ledger using 3-in. through screws.

Pulling secondary layouts

Secondary layouts are all the other layouts on beams or rim joists that reference the first layout. Use the rim joist that you squared to the ledger (that is, the house) as the reference for the secondary layouts. For the joist layout parallel to the rim joist, mark the adjacent joist and pull layout from that, rather than pulling directly from the rim joist. Extend the tape across the top of the beam, lock it so it won’t recoil, and register it on the first joist position. Then mark the layout on the beam, moving the ladder as necessary. Locking the tape frees up both hands for marking and avoids the excess hassle of having to work the tape every time you move the ladder. You could butt the tape to the rim joist instead of marking the adjacent joist, but then you’d have to move the ladder all the way down to the other end and work back to the rim. This may seem like a small difference, but many small efficiencies add up to a lot of saved work and time.

To extend the rim-joist reference, use a string line to transfer the layout to additional beams. Tack a 2x block to the rim joist at the house. Tack another 2x block to the rim joist over the first beam and then extend a string line that’s aligned with the blocks to transfer the layout. On this deck, the extended joists were sistered on the side with the blocks, meaning that the new joist layout was offset by 1-1/2 in. If we were going to sister the joist to the inside, we would have put the blocks to the inside. To continue the layout across the beams, align the tape to the string and mark the layout, again noting to which side of the mark the joist will land.

1. Register the tape on the joist layout adjacent to the rim joist and extend it the length of the beam.

2. Mark the joist layout on the top of the beam. Remember to indicate which side of the mark the joist will land on.

3. Place 2x blocks on the side of the rim joist. Place one block near the ledger and the other block over the beam.

4. Align the string when transferring the layout to additional beams.

5. Use the string as a reference to pull additional parallel layouts.

Pulling layout on an angle

Sometimes you need to pull layout on an angle. You can use a construction calculator to figure the distance between the joists based on the Pythagorean theorem (see “Pythagorean Theorem”), but it might be just as quick to pull a few measurements.

Pythagorean Theorem

A handy trick to have in your tool bag is the Pythagorean theorem, which states that for any right-angle triangle a2 + b2 = c2.

For example, if a = 6 and b = 8, then c = 20.

62 + 82 = 102

36 + 64 = 100

To figure the layout with a tape measure, hook the tape on the nearest joist and align the tape perpendicular to the joist with a Speed Square 1. Move the tape and square along the joist until the tape reads 16 in. to the framing on the angle, in this case a rim beam 2. Mark the joist location with a Speed Square 3. Slide the tape and square along the joist until the tape reads 32 in. and mark another joist location 4. Measure between the joist locations along the angle to find the on-center joist spacing 5. Now you can use this spacing to pull layout along the angle.

If you have a long run on the angle, it’s a good idea to establish joist locations at either end and pull layout to the center. If the layouts don’t line up, take half the discrepancy divided by the number of spaces and this is the distance the on-center number needs to be adjusted by. For example, say there is a 2-in. gap between the layouts pulled from either end. For ease of math, say there are 8 joist spaces on either side. With simple math you know the initial on-center joist space is 1/8 in. too short. Add 1/8 in. to that number, then pull layout again and you should be dead on.

1. When pulling layout on an angle, use a Speed Square to align the tape at a 45° angle to the last joist.

2. Measure 16 in. from the last joist, square to the rim joist, and mark the location.

3. Mark a vertical line on the rim joist to give yourself a reference when installing the field joists.

4. Slide the tape down and measure 32 in. from the last joist, square to the rim joist, and mark that location.

5. Measure the distance between the marks on the rim joist to discover the on-center joist distance along the rim joist.

Trade secret

The bed angle of most circular saws limits a bevel cut to 45° (or sometimes 51°). To cut a bevel at a greater angle, clamp a section of beam flush to the end of the joist. To calculate the saw angle, simply subtract the desired angle from 90°. Here, I am cutting a 58° angle so I set the saw at 32°

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Lithium-Ion Cordless Palm Nailer

Metal Connector Nailer

Drill Driver/Impact Driver