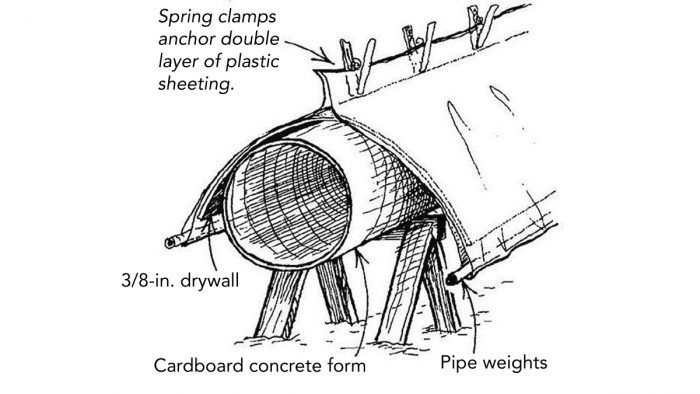

Drywall Bending Form

Use readily available materials to build a jig for making curved pieces of drywall.

When I had to bend some 3/8-in. drywall into sections for a coved ceiling, I hunted around for some readily available materials that could serve as a bending form and a press to apply even pressure to the panels. I found a 10-ft. long, 20-in. dia. concrete column form, and propped it up outdoors on sawhorses. This became my bending form. I centered a piece of drywall on it, finished side down, and sprayed water on its back. Then 1 arranged a heavy plastic tarp over the panel, as shown in the drawing. I doubled the plastic so that it could carry 3/4-in. steel water pipes, which hung down at the sides of the form and applied the necessary pressure to persuade the drywall into its arc. Where the edges of the plastic came together, I held them fast with spring clamps.

I had to wet the panels every few hours to get them to bend, but bend they did. When they took on the correct curve, I pulled away the plastic and let them dry until stiff.

I installed the curved pieces of drywall in a double layer, using drywall adhesive to laminate them. The resulting cove didn’t need curved wooden backing, and it took very little mud to feather the separate pieces into a continuous curved surface.

Bruce Misfeldt, St. Louis, MO

Edited and Illustrated by Charles Miller

From Fine Homebuilding #44