Elegant Wainscot From Drywall Scraps

Use strips of drywall to create custom paneling that will add detail and charm to most any room.

Synopsis: Although wainscot paneling can be an elegant addition to any room, traditional wood installations can be difficult, pricey, and time-consuming. Myron R. Ferguson has come up with a unique alternative: wainscot made with drywall scraps. The veteran drywall installer outlines his technique for saving drywall pieces bound for the trash and turning them into custom paneling.

Wainscot can improve the look of a room dramatically, but installing it typically demands a decent amount of money, time, and skill in trim, joinery, and finish work. If you’re willing to stray from the traditional approach, however, wainscot doesn’t have to be nearly so complicated.

I create wainscot by using leftover drywall (otherwise heading to the Dumpster) and decorative vinyl bead. Often, wainscot is painted, so why not make it out of dry wall? It’s far less expensive than wood, especially when a bunch of scrap is lying around a job site. Also, drywall doesn’t expand and contract due to temperature and moisture changes, so it stays looking good for a long time. My process demands a certain amount of skill, but assembly is far quicker than the traditional alternative—and the finished look is just as great.

Plan the electrical layout for clean outlet installations

Working electrical receptacles into a wainscot assembly can cause problems, especially when symmetry and clean lines are the goal. With proper planning, however, outlets can be easily integrated into a wall without looking as though the wainscot were merely built around them.

Whenever possible, I visit the job site before any electrical work is done and figure out the approximate layout of the wainscot. I tell the electrician to run wire to the general location of the boxes and to leave it looped in the wall.

When I’m installing the drywall and wainscot, I cut a hole in the wall where I want an outlet, reach in, and pull the looped wire through. I typically place electrical boxes in one of two places, either in the exact center of a panel or in the center of one of the stiles. I use an old-work box for either installation (see the article “Problem-Solving Electrical Boxes” in FHB#186)

Another option is to position all the outlets horizontally in the baseboard. This layout requires you to install taller baseboard, but it makes for an easier wainscot installation because the electrical boxes don’t interfere with the layout.

Consider door and window transitions carefully

Nowhere is quality craftsmanship more evident than where wainscot meets a door or window opening. Done well, the transitions look seamless and well planned. Every room is different, though, so perfecting these details can take some creative thinking.

When possible, which isn’t often, I let the wainscot butt directly into the door and window casing while allowing the window stool to overlap the wainscot. Most likely, the wainscot stands proud of the molding, though. In these situations, I butt the wainscot to a pilaster at a door opening, or I build out the casing to accommodate the aforementioned butt joint.

Create a layout that suits the room

Traditionally, wainscot is built to a height of 32 in. off the floor, but it doesn’t have to be limited to that dimension. Ceiling height, window height, and homeowner preference all can affect the decision about wainscot height. Stile width and spacing are established once the rails are installed. Each stile’s placement is determined by what looks best for a given room.

Stiles are secured with spray adhesive

The likelihood of each stile aligning perfectly with every stud is slim, so relying on screws to secure each stile isn’t practical. Spray adhesive is perfectly suited for this job. i’ve tried several brands and like the product made by trim-tex best for the sole reason that it applies adhesive in a wider, more-consistent pattern than other brands.

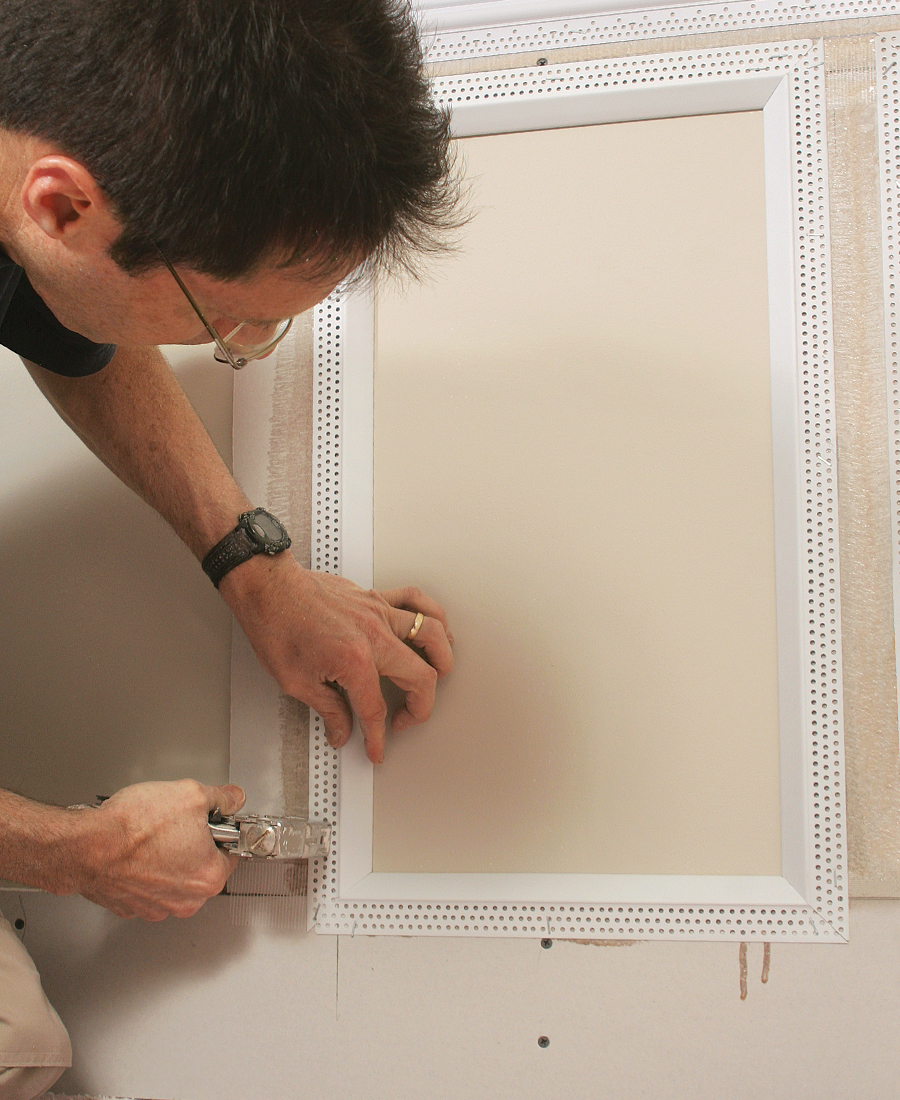

Specialty bead adds style and durability

The vinyl bead i use for wainscot is secured with a combination of 1/2-in. divergent staples and spray adhesive. Vinyl bead is a great product for this project because i can easily sand or scrape excess compound off it without causing any damage; it also takes paint well.

Choose bead carefully

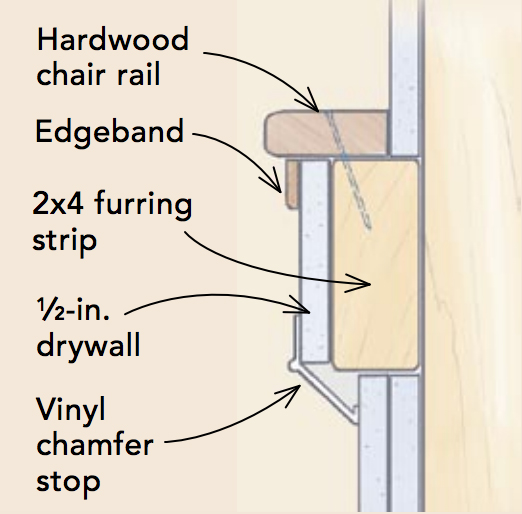

Designed for single or double layers of 1/2-in. or 5/8-in. drywall, Trim-Tex vinyl decorative bead comes in 8-ft. or 10-ft. lengths and a variety of different styles. I use decorative L bead as chair rail because its offset design covers the top edge of the top rail. The chair-rail bead is not an option here because it’s designed to be used only on flat surfaces. Chamfer stop creates a clean, panelized look. Like all vinyl bead, it can be cut on a power miter saw using a plywood blade with the teeth reversed to cut the vinyl cleanly.

|

|

|

Cost: $2 to $5 per piece

A careful mud job creates a clean finish

I’ve used several different types of joint compound when making wainscot. each type performs fine, but depending on time constraints, you need to choose a specific product. setting-type compound sets up the quickest, and when used for the first coat, it allows you to apply the second coat the same day. otherwise, wait at least 24 hours between coats of compound.

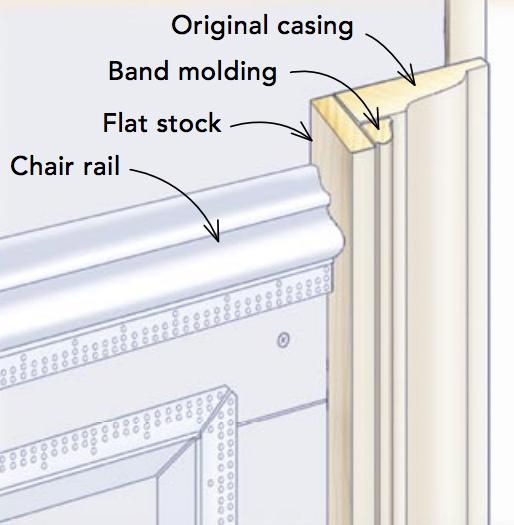

| Make casing thicker to accommodate wainscot

Wainscot shouldn’t stand proud where it meets window and door casings. You can build out the thickness of casings with a combination of molding and flat stock. (see “Adding Detail With Built-Up Molding” in FHB #172) |

|

To view the article as a PDF, click the View PDF button below.