Fight Mold With Paperless Drywall

Switching to fiberglass-faced drywall makes kitchens, baths, and basements more mold resistant, but it also means adopting some new work habits.

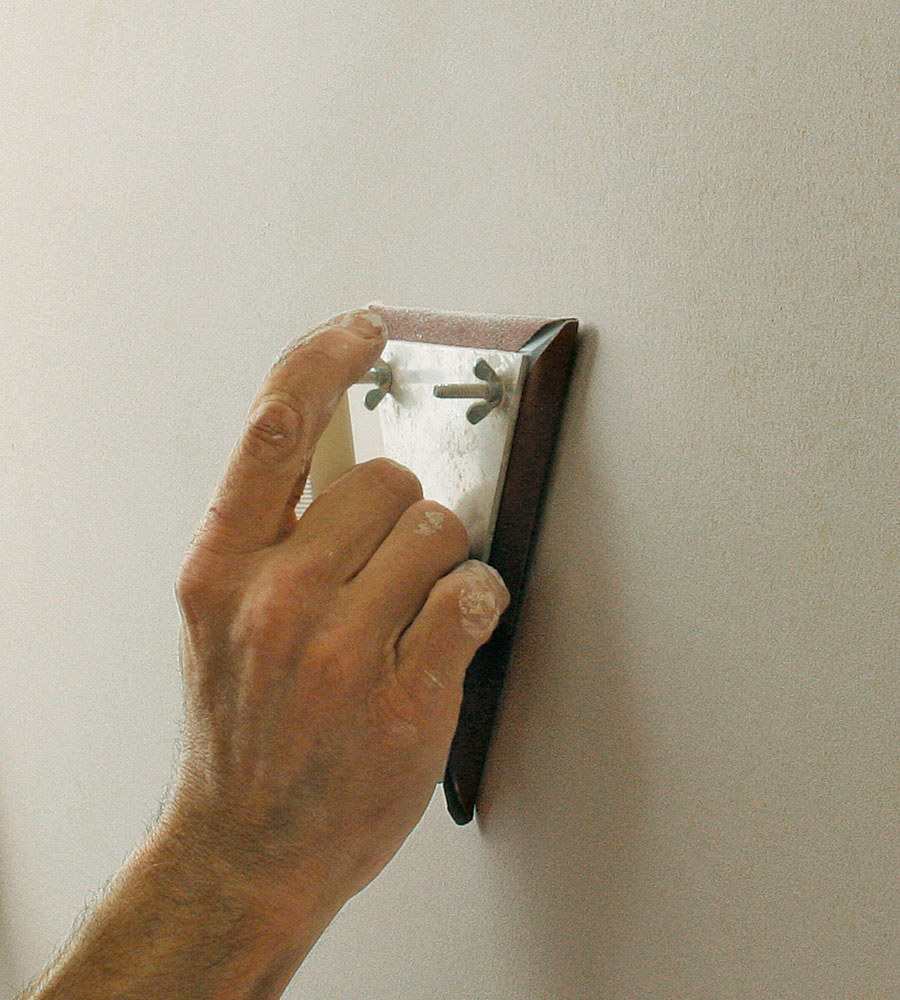

Synopsis: For walls in damp environments, such as bathrooms, kitchens, and basements, paperless (or fiberglass-faced) drywall is a good alternative to the traditional paper-faced material. However, working paperless drywall entails learning a new set of rules. Drywall expert Myron R. Ferguson shares his advice on four new work habits to adopt when you’re working with paperless drywall. Ferguson advises using both screws and adhesive to fasten these panels. Also, he advises using hand tools instead of power tools to minimize dust. Inorganic tape helps with the mold resistance of the drywall. Finally, Ferguson says to sand the surfaces that you can, but to skim-coat where you can’t.

Let’s face it there’s been a lot of talk about mold in the past few years. The topic has gotten plenty of attention in the news, has been the focus of lots of building-science research, and has made many homeowners nervous. Here’s the thing: Mold spores are everywhere and are nearly impossible to avoid, never mind eliminate. What we can do, though, is help to prevent those mold spores from taking root in our indoor living spaces. That’s where products like paperless drywall come into play.

Mold needs four things to grow: oxygen, water, a temperature between 40°F and 100°F, and an organic food source. Considering this group of ingredients, it’s not surprising that mold is commonly found on lumber in the basement, on the wall behind the sink in the kitchen, and on the wallpaper adhesive in the bathroom.

The first step in preventing mold growth is to get firm control over the level of moisture in the air (see “Breathing Fresh Air Into Bathroom Ventilation,” online at FineHomebuilding.com). After that, the focus should be on eliminating the organic food source.

Paper is a gourmet meal for mold

Because mold decomposes organic (once living) material as a food source, the paper facings on the front and back of drywall are an easy target. Most drywall manufacturers have fought this problem by offering modern versions of the old wax-coated “greenboard” that has been used in bathrooms for years. Many of these modern paper-faced products even scored a perfect 10 on the ASTM standard for mold resistance. For the ultimate peace of mind, though, a few drywall manufacturers have now created paperless drywall, removing all sources of organic food.

TIP: I often leave screws slightly proud and then sink them by hand for a perfect dimpled depth.

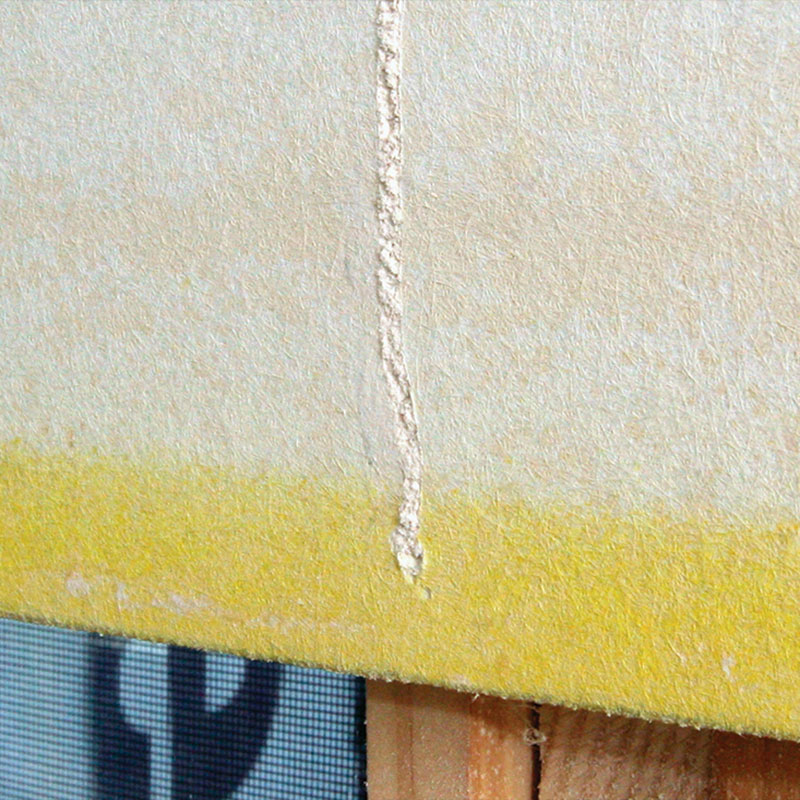

By replacing drywall’s paper facing with an inorganic fiberglass mat, products like DensArmor Plus offer excellent mold resistance compared to standard paper-faced wallboard products. But don’t get a false sense of security; these products are only as good as the installation.

For example, I once had a truckload of paperless drywall delivered to a job site, and when I started to install the product, I noticed that the back side of one sheet was dirty. I guess the drywall must have been stacked at a convenient height for a lunch or a coffee break because somebody had spilled coffee or soda on it. Then dirt and sawdust from the lumberyard and the job site clung to the sheet. If I hadn’t noticed the stain and tossed the sheet, I would have quickly defeated the mold resistance of the paperless drywall. If paperless drywall isn’t handled properly or installed correctly, the job may be little more than a pricier route to the same place.

TIP: Large offcuts falling to the floor can kick up lots of dust. To avoid this, leave a little bit of drywall at the edge of the cut, then slice the piece free with a utility knife and carefully remove it.

New Work Habit #3: Switch to inorganic tapePaper tape set in premixed joint compound is a manufacturer-approved option for finishing joints on paperless drywall, but most encourage the use of setting-type compound (photo below left) and mesh tape, which further reduces the chances of mold growth by removing a food source. Standard mesh tape is widely available and a fine choice, but I prefer FibaFuse fiberglass tape (photo below right; sgtf.com), which has a thinner open-fiber weave. Either way, these tapes come with their own set of rules. |

TIP: Use a relatively new taping knife for working with mesh tape. The older the knife, the sharper the edges will be.

Paperless products behave similarly to standard paper-faced drywall, but they are a bit more fragile to handle and install, require different products to tape, and typically must be finished to a more uniform surface before being painted. Learn these quirks, though, and you’re likely to have a successful experience with paperless products.

Click the View PDF button below to see the article as a PDF:

View Comments

Would an oscillating tool (like a Fein) be better for cutting the fiberglass wallboard than a rotary tool? I know when I use my Fein on wood the dust created generally drops right below the cut and I don't see much of any airborne dust.