How to Hang Drywall on a Gable End

This gypsum job is tougher than most, and not just because of the high ceiling.

Synopsis: Hanging drywall can be a difficult job to start with, but hanging it on a gable end makes the work even tougher. Drywall guru Myron R. Ferguson describes his process for hanging drywall on a gable end. Ferguson says that it’s OK to start at the bottom of the wall; having a layer of drywall at the bottom provides a surface on which to stack subsequent layers. Ferguson advises taking care with seams and screws. He also outlines his techniques for cutting arches and for cutting angles.

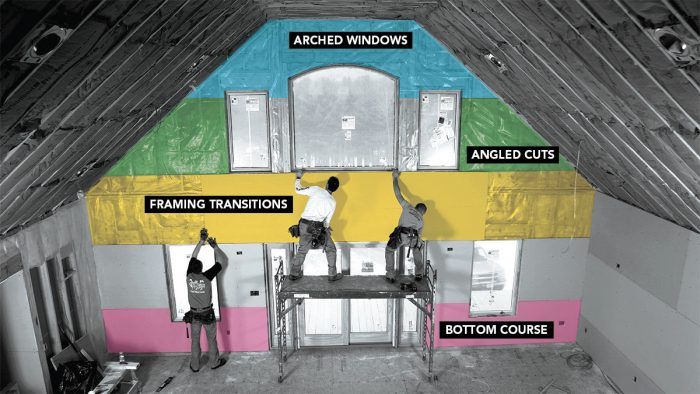

Homeowners love large rooms with high cathedral ceilings and lots of windows, but to a drywall contractor like me, tall gable-end walls are a perfect storm of drywall-hanging obstacles. Never mind the 20-ft.- to 30-ft.-tall ceilings—the gable wall alone involves lots of tricky cuts; structural headers, framing transitions, and solid blocking that create bumps and dips; and an increased chance of structural settling. All these things could lead to drywall cracks, visible seams, and popped fasteners.

Of course, no two rooms are exactly the same, but the project shown here is a textbook illustration of the potential problems. Even if your gable-end wall looks different from this one, my general guidelines can still be applied. Just plan thoughtfully, and focus on the common trouble spots.

Fewer seams, fewer problems

Taped seams are more likely to crack than drywall itself. Reduce the amount and the length of seams, and you reduce the chance of future problems.

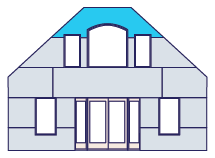

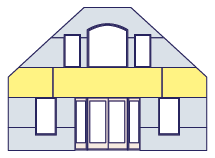

One way to reduce the length of the horizontal seams is to rip the bottom course of drywall to a height that minimizes or eliminates seams running uninterrupted from one end of the wall to the other. In this way, the windows and doors become termination points, and they break up the length of the taped seams.

It’s OK to start at the bottom

Unlike working in a room with 8-ft. or 9-ft. ceilings, where the first sheet of drywall can be lifted easily to the top of the wall and fastened, (1) stacking the several courses of drywall necessary to cover a tall gable end wall is easier than holding the panels up and working your way down. Also, when measuring for the angled cuts where the wall meets the cathedral ceiling, it’s easier to take measurements from the top edge of a row of panels that is already installed. The only caution here is to make sure that you leave a space along the floor in case the wall settles. (2) Some scraps of drywall work well to keep the first row of panels off the subfloor. |

I got lucky on this job. The distance from the top of the ground-level windows and doors to the bottom edge of the upper windows was 48 in., just the right width for a sheet of drywall and no need for a long horizontal seam. Even if this center section had been less than 48 in., I could still rip a sheet to fit the width. If it were more than 48 in., a 54-in.-wide sheet of drywall could be ripped as necessary. Any wider than 54 in., though, and a horizontal seam is a must.

If you are forced to have a long-running horizontal seam, avoid putting it on or near a framing transition or a row of blocking. These spots are more likely to leave you with an obvious bump in the finished wall.

Long sheets reduce butt joints

Vertical (butt) seams are the next thing to consider. They are hard to fasten and hard to hide, and on a big gable wall that is likely to shift and settle over time, they are the most likely place to crack.

|

Again, use windows, doors, and angled ceilings as termination points wherever possible. In areas where this isn’t possible, use the longest sheets of drywall that you can manage, and locate butt seams away from the center of the room, where they will be most obvious. If you can cover from one end of the gable wall to the other without any butt seams, perfect.

Fastening location matters, too

Unfortunately, a successful layout doesn’t depend only on seam location. Fastening always seems to be an issue on gable walls. Obviously, each sheet needs to have the appropriate number of fasteners, but with the increased likelihood of settling, lumber shrinkage, and framing transitions not being perfectly flush, I have to be especially careful with screw placement. Careless fastening will just about guarantee popped fasteners within the first year after the job is complete.

Typically, a thick bead of drywall adhesive lets me get away with using fewer fasteners, and it all but eliminates the chance of popped screws. But if the gable wall is covered with a poly vapor barrier, as it was on this job, using drywall adhesive is not possible. The best option is to use typical 1-1/4-in. coarse-thread drywall screws (no nails, please) set 16 in. on center vertically in each framing member. Like everything else on gable walls, though, there are exceptions to this rule.

I avoid putting more than one horizontal row of screws into structural headers, and I prefer to avoid fastening the drywall to transitions in framing, such as where the upper wall meets the lower wall. These two areas are most likely to move over time, and movement will lead to screw pops. I keep screws about 6 in. down from where the wall meets the ceiling for the same reason.

Work around the room one course at a time

You might think it’s easier to hang the entire gable wall first, then butt the ceiling panels to the wall to hide any sloppy gaps at the angles. I actually prefer to hang the ceiling first so that the wall piece is providing support for the ceiling. Trust me, though, getting a tight joint between the gable wall and the angled ceiling looks far more difficult than it is.

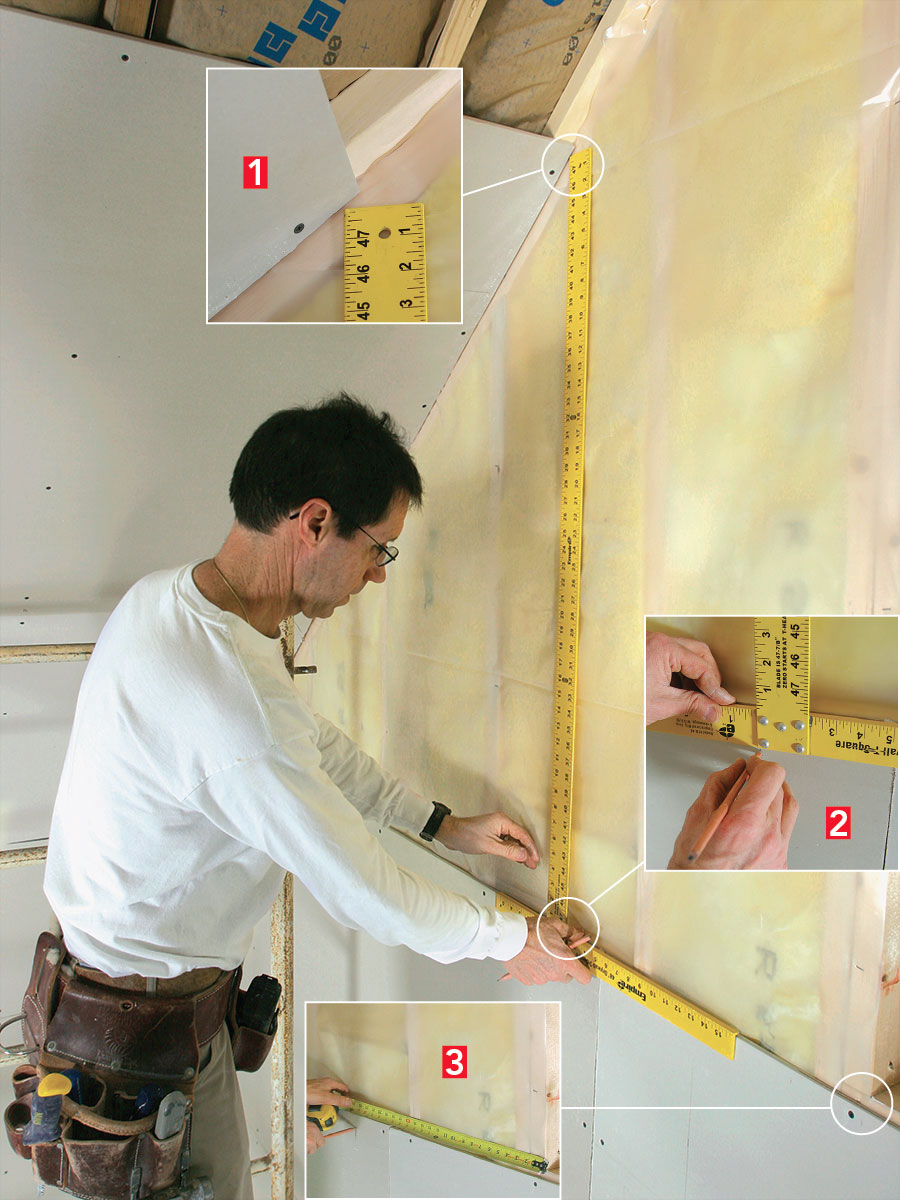

Connect the dots to cut arches

Cutting out rectangular window or door openings in drywall is easy because you can run a utility knife or drywall router along the edge of the rough opening. Arch-top windows, on the other hand, don’t have arched rough openings to use as guides. Instead, (1) take several measurements from the ceiling down to the arched window, marking the measurements on the ceiling as you go. The more measuring points you have, the more accurate your arched cut will be, but at the least, you need to know the high and low points.

After the sheet is tacked in place, (2) mark the measurements on the drywall, and connect the dots with a pencil. Then it’s as simple as following the pencil line to remove the scrap. You can use a drywall router or a wallboard saw, or you can make several passes with a utility knife. (3) Don’t worry if your arched cut isn’t perfect; the extension jambs and the window casing will even things out later. |

To make the installation run smoothly, I always hang the first two rows of drywall on all four sides of the room while I’m standing on the floor. From there, I prefer to work from scaffolding, again hanging all four sides of the room before bumping the scaffolding up to the next height. I like to have two people on the scaffolding do the drywall hanging and one person on the floor do the cutting. It’s also a huge help to have a drywall lift so that each sheet can be lifted safely to the top of the scaffolding.

Click the View PDF button below to see the article as a PDF:

Be careful with seams and screws

Be careful with seams and screws