Lime-Plaster Installation Over Drywall

This one-coat, environmentally and budget-conscious wall finish has a lot to offer.

For builders or homeowners who are concerned about the environmental and social impacts of the materials used in their homes, lime plaster has a lot to offer. New Frameworks Natural Design Build in Vermont uses it often, including as an interior finish in this deep-energy retrofit in Charlotte, Vt.

There are four main binders for plaster: cement, gypsum, lime, and clay. In the natural-building community, lime and clay generally rise to the top as the most environmentally and socially responsible options.

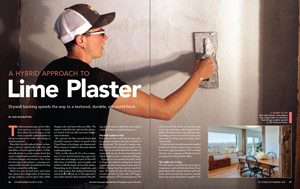

For this process, drywall is used in place of lath as a substrate because it is much less expensive and labor intensive to install, bringing the plaster finish into the realm of affordability for homeowners on a budget. To give the plaster something to grab onto, they prime the drywall with a mix of Elmer’s glue and handfuls of sand.

The plaster used in this process is simply a mix of Type-S mason’s lime, limestone sand, and water. It is, very nearly, liquefied rock that is troweled onto the walls. Even in the 1/4-in. thickness used in this house, it’s possible to sculpt outside corners to give a softer look to what will become rock-hard walls. As it cures, the plaster absorbs carbon dioxide from the air and turns back into limestone in the shape the plasterers put it in. While lime production does produce some greenhouse gasses, this is partially offset during the curing process.

The white lime mixed with the white sand produces a warm, bright plaster that is both beautiful and durable. Rather than use multiple coats, as is the case with some other plastering methods, this process requires just one coat, making it a less fussy, more affordable finish for the Earth-conscious builder or consumer who doesn’t want to break the bank.

For more on Lime Plaster:

- A Hybrid Approach to Lime Plaster

- A Short Guide to Lime-Plaster Trowels

- Add Color to Lime-Plaster Walls

- From Rock to Dust to Rock Again: An In-Depth Look at Hydrated Lime

- Lime-Plaster Transformation: A Slideshow

View Comments

Those un-taped joints are going to crack. Not, they may crack. They will crack.

The social impact nonsense is for the crazies and whack jobs.

It seems very likely that the previous poster is right about the joints, but unless he's actually used this process I cannot agree with his absolute position. I would very much like to see a followup article on how well this holds up.

I think the reason our world is so angry and screwed up is that things like social impact are relegated to crazies. Being good should be a higher priority for everyone.

Finally, my own question: do you leave it raw or prime and paint? If left raw, doesn't it lose a lot of crumbs and bits that fall into the carpet or onto the floor? I know the stucco on my house is always crumbling off a grain or two at a time.

Turns out if you read the "For more on lime plaster" links at the end of the article, my questions are answered and more.

This is not a plaster finish in any sense of the traditional use of the word. This is best described as a mortar finish.

Lathe is more labour intensive to install? The old wooden slats, yes, but not the more recent plasterboard lathe. I watched my parent's home being built in the '70's and that lathe went up very quickly. The fact that both a thick rough coat and a final finish coat of plaster were going to be applied over-top, meant that pieces didn't have to fit well and in fact the plaster would key better if there were spaces.

A few buckets of mud applied to taped seams are more environmentally damaging than walls that are completely covered in this lime mixture? Does this company have any idea of the energy required to produce lime? Is this company aware that there is a shortage of sand in this world due to the vast quantity of construction that taken place over the last 2 decades? (One can't use desert sand in concrete) The rivers are not re-generating the sand fast enough to replace what is being removed.

user-286557 is absolutely correct. It WILL crack. The scratch coat of traditional plaster included ingredients such as horse hair to prevent such an outcome.

This is simply a company trying to build a business with fake environmentalism to "virtue signalling" purchasers.

Lovely video and lovely walls. Well done.

Could this mixture be applied to osb or plywood, instead of drywall?

I am currently planing to do almost the same thing you have done here, but I wonder if you find it necessary to also add Portland to this mix. Did the type s lime and sand end up being sufficient?