Planning a Drywall Job

Get these layout tips down and you will end up with a better job in less time.

Planning a drywall job involves more than just selecting the right type of drywall. You’ll also need to estimate materials, make sure the materials (especially the longer-length panels) are available when needed, plan access for the drywall, and make sure you have enough help on the job site to maneuver the cumbersome panels. But before you start figuring out a material list for the job, there are some basic layout principles that you should keep in mind.

General layout guidelines

No two drywall projects are exactly alike, and each presents a unique set of challenges. But I’ve found that keeping the following items in mind helps just about any job go smoothly.

Always think of ways to eliminate unnecessary joints when planning the layout of a room. Use the longest panels possible; remember that most types of drywall are available in lengths of up to 14 ft. or 16 ft. You may be tempted to use all 8-ft. lengths because they are lighter and easier to handle (and often cheaper), but don’t. Using all 8-ft. panels creates too many seams that are difficult to hide. Keep in mind that fewer seams means less taping.

Ceiling panels can be attached either perpendicular to the ceiling joists (my preference) or parallel to the joists. Make sure that the type of drywall you intend to use is approved for the stud or joist spacing; drywall is stronger in the long direction. In addition, the framing spacing may affect the direction in which the drywall is hung.

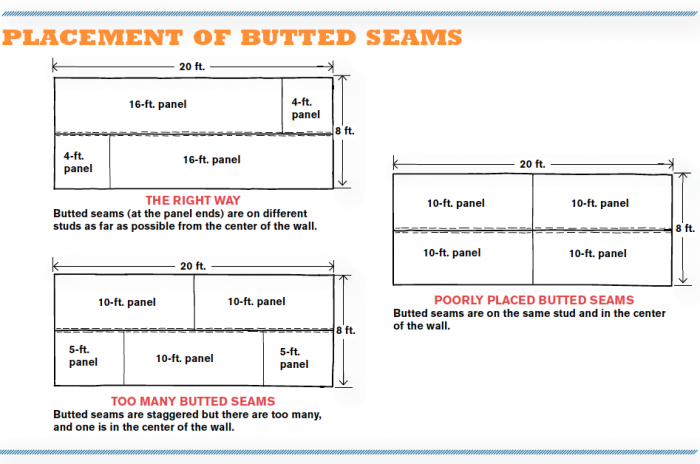

Always try to avoid butted seams A butted seam is a joint created when two untapered panel ends are joined together on the same framing member. If you have to use butted seams, stagger them as far as possible from the center of the wall. For example, if a wall is 8 ft. high by 20 ft. long, it is not a good idea to use four 10-ft. panels (see the drawing “Placement of Butted Seams”). You’ll end up with more than two butted seams on one wall or with seams on the same stud in the center of the wall. Instead, order two 16-ft. panels and one 8-ft. panel, and arrange them as shown in the drawing. This way, there are only two butted seams on the wall and they’re away from the center, where they are easier to hide when taping and finishing.

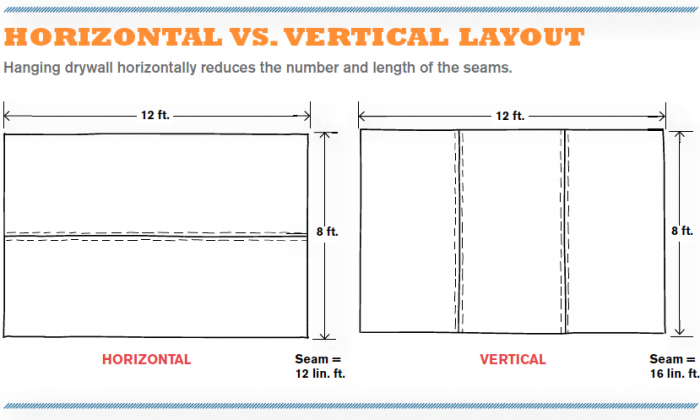

On walls that are more than 4 ft. wide and no higher than 8 ft., hang the drywall horizontally (perpendicular to the studs). This technique reduces the linear footage of joints and also places the horizontal joints at a good height for taping (see the drawing “Horizontal vs. Vertical Layout”).

For walls that are more than 8 ft. high, consider using 54-in.-wide drywall panels, which can greatly reduce the linear footage of seams. Fifty-four-in.-wide drywall is only available in lengths of up to 12 ft. That could be a problem in larger rooms or areas where the walls are over 9 ft. high. In those cases, it may be better to install the drywall vertically. The goal is to use whichever method produces the fewest seams (measured in linear feet) to tape.