Repairing Popped Drywall Fasteners

Secure nail pops and similar problems with additional screws before fixing the visible damage.

Popped nails and screws are one of the most common drywall problems. Fortunately, they’re also among the easiest to repair. The problem occurs when the drywall is not fastened tightly against the framing, when the framing lumber shrinks or twists, or when an object strikes the wall. With time or abuse, joint compound comes loose from the fastener and pops off, exposing the fastener head or pushing out the joint tape. Fastener pops may appear soon after the wall or ceiling is finished, or they may become visible several years later.

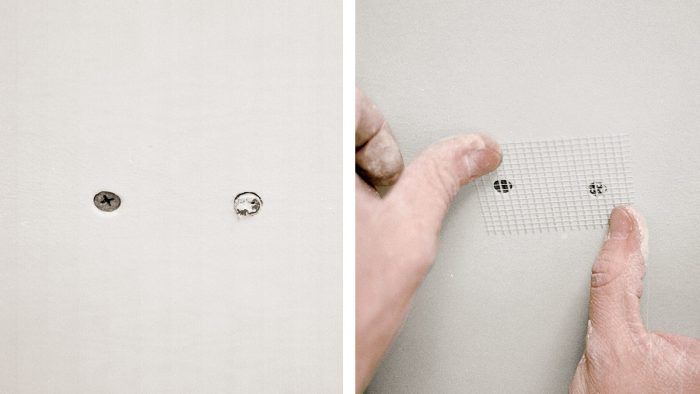

Whatever the cause, there’s a quick fix: Place another drywall screw about 1-1/2 in. away from the popped nail or screw, and then remove or reset the popped fastener. Apply hand pressure to the panel next to the area as you set the new screw. After the new screw or screws have been set, check the popped fastener and reset it again, if necessary (or simply remove it).

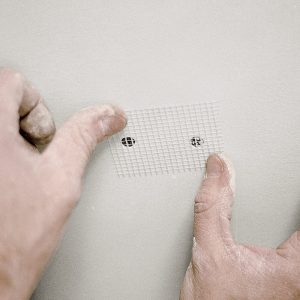

If the paper surface of the drywall has not been damaged, the fasteners can be finished with three coats of joint compound and sanded lightly. If the paper surface has been torn or the core of the drywall has been damaged, remove the loose material, fill the gap with joint compound, and then apply a small piece of mesh tape to the damaged area. Cover the repair with three thin coats of joint compound. Keep the compound thin over the patched area and feather it out as wide as necessary so that it blends into the wall.

| WORK SMART: If the face paper is torn, apply mesh tape to reinforce the repair. |

Fastener depressions

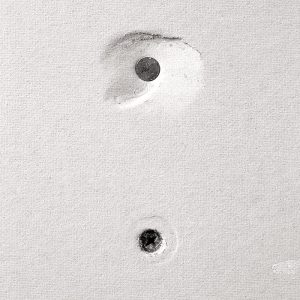

Areas around fastener heads where the joint compound is recessed below the surface of the panel are called fastener depressions. Depressions usually occur for one of two reasons: Either too little joint compound was applied during taping or the fastener was driven too deeply into the panel surface, damaging and weakening the panel’s face paper and gypsum core. When sanded, the compound is removed from the indentation because the drywall pushes in as you sand over the loose fastener. A fastener depression often isn’t visible until after it has been painted.

To diagnose the problem, push firmly against the drywall panel alongside the depression. If the panel is secure, you simply need to apply another coat or two of joint compound and then lightly re-sand the area to even out the depression. If the drywall moves in and out even a slight amount, the panel is damaged. To correct the problem, place a screw 1-1/2 in. away from the original fastener, and then press against the panel again to check for movement. If the panel is now tight, use a taping knife to remove loose material from around the original fastener, and then reset the nail or screw. Cut a piece of fiberglass-mesh tape to cover the fasteners, re-tape the area, apply three coats of joint compound, and lightly sand it once it’s dry.