5 Reasons to Own a Blower Door

As a contractor, investing in blower-door equipment is a means to diversify your skill set, toolbox, and income stream.

By now most of us know what a blower door does and the basics of how it works. All energy auditors and raters own one, and a few insulation contractors I know have purchased their own. As a contractor, does it make sense to invest upwards of $3500 and to take the time to learn how to operate this piece of equipment? I know of only a few contractors who have made the investment. Is it right for you? It might be. Off the top of my head, I can think of five reasons to own one.

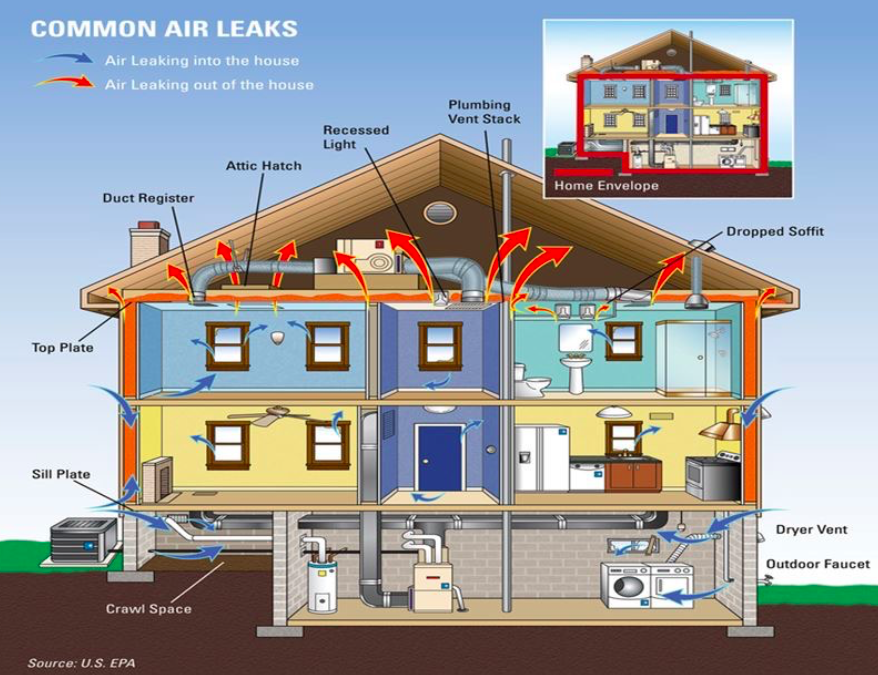

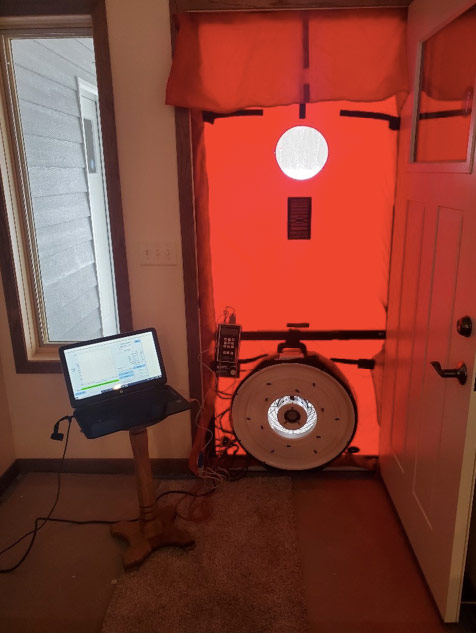

1. It’s an essential tool for finding air leaks in a structure, and it’s a code-required test in many areas. The 2012 IRC included the first code requirement in the U.S. to test all newly built homes to verify the air tightness level. The only way to do that is with a blower-door test. Recent codes include the language: “Where required by the building official, testing shall be conducted by an approved third party.” You may not be able to conduct your own blower-door testing for code compliance, but you can definitely test the home before the third party arrives. The blower-door testing I do for code compliance includes additional charges, if the house doesn’t pass. So, searching for air leaks and fixing any problem areas before the test for compliance is conducted saves money.

2. It provides an additional—and less demanding—revenue stream for your business. I bought my blower door back in 2009 to supplement my contracting business during a downturn in the economy. I trained to be an energy auditor, and that side of my business has seen steady growth over the past 10 years. Testing homes and conducting energy audits isn’t as physically or mentally demanding as working as a builder. I can see myself supplementing my retirement by continuing to perform this type of work into my 60s and 70s.

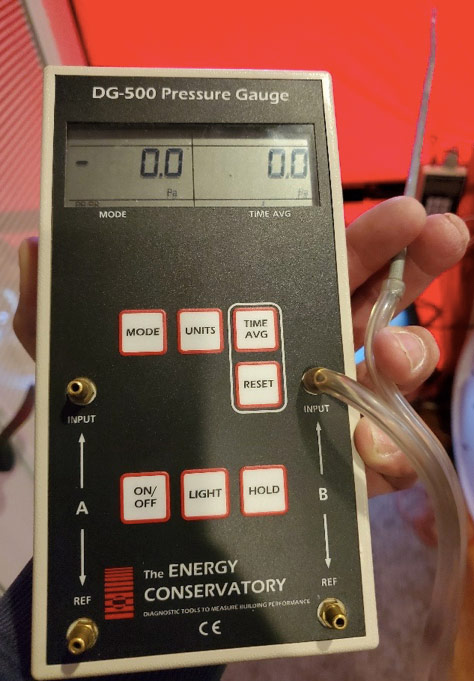

3. It’s a multi-purpose tool. Blower doors come with several different components: a frame and shroud that fit tightly in a doorway; a fan and fan speed control unit used to move air; and the “brains” of the blower door—the pressure gauge or monometer. I own a couple diagnostic tools that require a monometer, a pressure pan, and an exhaust fan flow meter. For example, a duct-blaster test requires a monometer, and a Combustion Appliance Zone (CAZ) test for the backdrafting of appliances requires a monometer. Plus, a monometer indicates if a room is being pressurized or depressurized by the forced air from heating and cooling equipment. It’s useful tool, given today’s “trust but verify” work ethic.

4. There’s no waiting for a test. Because I’ve owned my own blower door for a long time, I tend to forget about the complexities of scheduling a test. Travis Brungardt, builder and partner at Catalyst Construction in Kansas City, MO, speaks to this issue, saying, “Scheduling an energy auditor for some point down the road costs us time. With the blower door (in concert with other tools), we can run the test whenever we need to in order to locate any problems. Then, we can run it again immediately after our attempt to resolve any issues to know if we were successful. The volatility of construction schedules makes planning these moments in advance difficult, so while we could hire a baseline blower-door test before we start and another one after we are done to confirm our efficacy, that would eliminate a lot of opportunities for us to do the most good. Owning our own blower door enables performance improvement as a byproduct of convenience. That knowledge is worth the investment.”

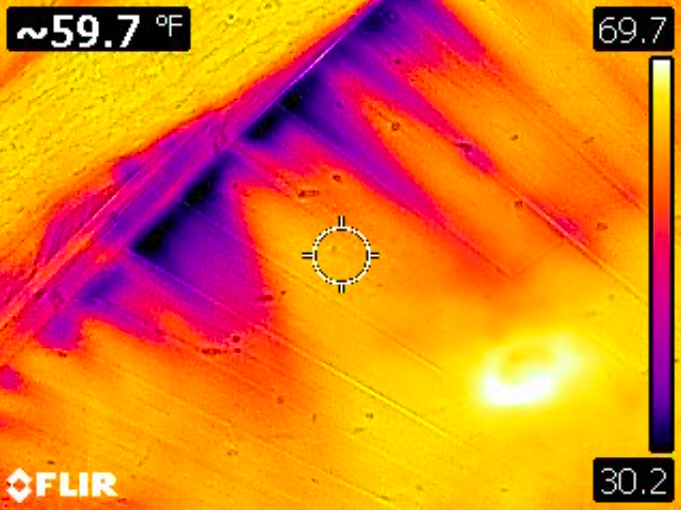

5. It’s an educational tool. Using a blower is an opportunity to learn where structures usually leak air. Foundation-to-framing connections, where the walls meets the ceiling, around windows and doors, and through penetrations in assemblies are all traditional leak points. Seeing those leaks first-hand often results in contractors making changes to their building techniques, which tends to produce better buildings. When you become experienced in using a blower door, you will have a better understanding of what the test results are telling you.

I asked Jake Bruton of Aarow Building in Columbia, MO, why he wanted his own blower door. He replied, “When I bought my first door in 2014, it was because I didn’t understand what the numbers meant. I figured the best way to understand it was to have one on hand. Nobody in my market owned a door back then; I believe I was the first. Since then, the main reason I own one is because I want to verify performance prior to an expensive rater coming to test. If I can run the door the day before they are scheduled, I can find any issues and resolve them. I also have the ability to play around and find solutions that I wouldn’t otherwise find. When the HERS rater is on-site to run a blower-door test, we want them in and out ASAP to keep costs low. When it is us, we can run the entire day and explore different ideas.”

The tool does require a significant financial investment—mine is the most expensive tool I own, after my truck. And it takes time and training to understand how to operate it and interpret the information it provides. But in my experience, a blower door pays for itself in the end.

Originally published on GreenBuildingAdvisor.com. Randy Williams is a builder and energy rater based in Grand Rapids, Minnesota. Photos courtesy of the author, except where noted.