Deep-Energy Retrofit for an Adaptive-Reuse Project

A historic brick warehouse is turned into a live-work space using building-science principles.

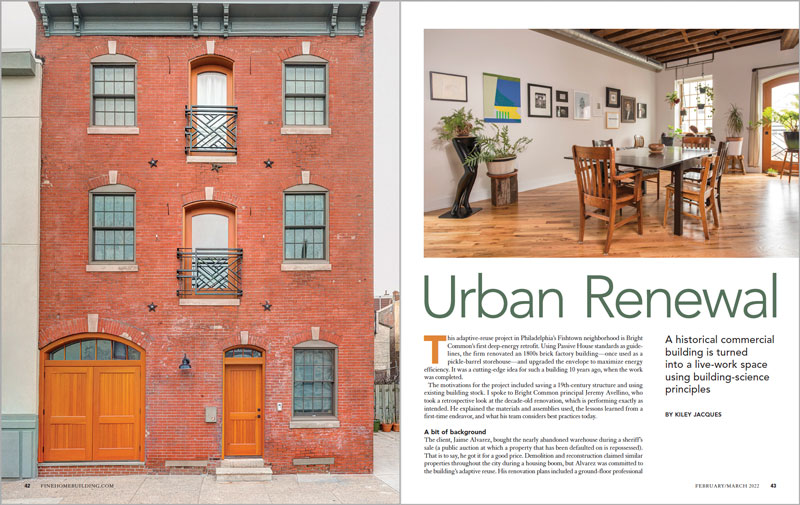

This adaptive-reuse project in Philadelphia’s Fishtown neighborhood is Bright Common’s first deep-energy retrofit. Using Passive House standards as guidelines, the firm renovated an 1800s brick factory building—once used as a pickle-barrel storehouse—and upgraded the envelope to maximize energy efficiency. It was a cutting-edge idea for such a building 10 years ago, when the work was completed.

The motivations for the project included saving a 19th-century structure and using existing building stock. I spoke to Bright Common principal Jeremy Avellino, who took a retrospective look at the decade-old renovation, which is performing exactly as intended. He explained the materials and assemblies used, the lessons learned from a first-time endeavor, and what his team considers best practices today.

A bit of background

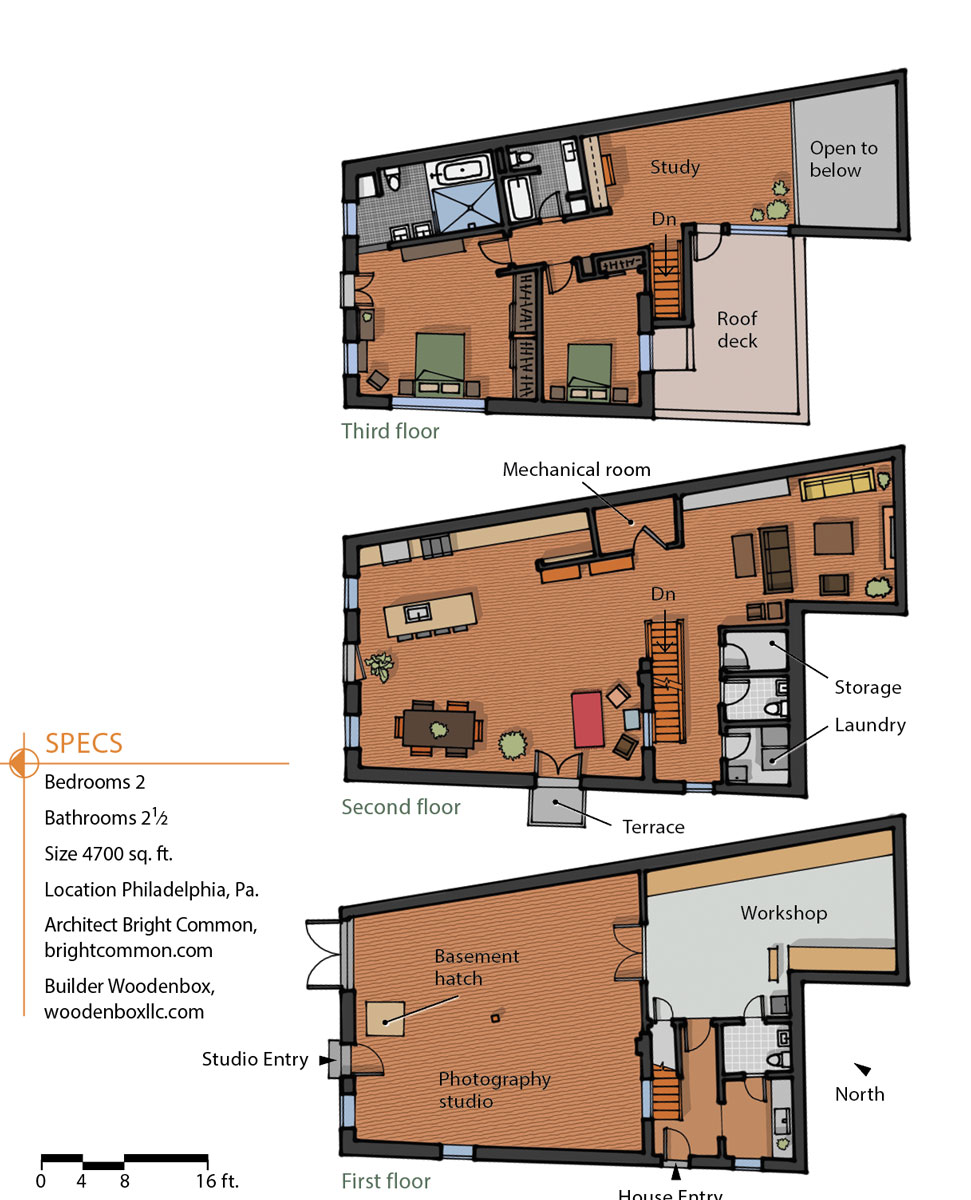

The client, Jaime Alvarez, bought the nearly abandoned warehouse during a sheriff’s sale (a public auction at which a property that has been defaulted on is repossessed). That is to say, he got it for a good price. Demolition and reconstruction claimed similar properties throughout the city during a housing boom, but Alvarez was committed to the building’s adaptive reuse. His renovation plans included a ground-floor professional photography studio and living space on the upper floors.

Upgrading the building to perform close to Passive House levels was not part of Alvarez’s plans, but when Avellino presented the idea of a deep-energy retrofit, he was all in. Because the building was reasonably priced, Alvarez could fund the energy upgrades.

Not surprisingly, a code-compliant building intended for both living and working required a zoning variance. There were two parcels that included the warehouse and an empty side yard, and they needed to be consolidated. Doing so, however, didn’t meet the requirements for setbacks and open space. Avellino describes the solution as “more subtraction than addition.”

Given the large amount of floor space and the lack of daylight and natural ventilation at the rear of the building, the plan called for removing a portion of the third floor to create a double-height living room with an east-facing bay of operable skylights. The room receives morning light and captures fresh air. Once the lots were consolidated, there was an opportunity to cut new windows into what was previously a fire-rated party wall and to relocate the main entry door to the side yard while keeping the original street-facing door as the public studio entrance.

Rebuilding a hollowed shell

The 19th-century triple-wythe brick warehouse with timber-frame infill was deemed structurally sound. The original 2×6 diagonal hemlock plank flooring was salvageable as well. There were some roof leaks that needed to be addressed, and the 1-in. concrete “rat slab” (traditionally poured over a dirt floor to keep out rats) was cracked and heaving. The outer wythe of the brick walls is a fired-clay brick and had held up well, but the inner faces are unfired clay or salmon brick, which is soft and chalky; it is meant

to receive a plaster finish, not be left exposed as it had been. The interior of the outside walls had been furred out for drywall in the 1990s, but all of that was torn out during Avellino’s retrofit.

An unpermitted rear addition, estimated to have been built in the mid-1990s, was failing due to cheap construction techniques. The 2×4 walls were improperly finished in stucco, insulation was sparse, and there was no water-resistive barrier or other water-management strategy in place. As a result, the addition was full of rot and mold. Plus, the windows had been installed on the property line, which is a code violation. According to Avellino, it was built to fail and was subsequently torn down.

“The fact that the original structure was in such solid shape compared to the 30-year-old addition spoke volumes to me about the differences in building techniques,” Avellino says. “We wanted to keep and restore the main building, but couldn’t follow those old construction methods. The biggest question was what to build in place of the torn-down addition,” he explains. “That became a point of research and exploration. I was reading research papers on something called a deep-energy retrofit, which I knew nothing about. It seemed abstract.”

Foray into building science

This was Avellino’s first attempt at a deep-energy retrofit. He wasn’t a certified Passive House designer yet, and was piecing together information from Building Science Corporation, Fine Homebuilding, Green Building Advisor, and other sources. “This was three years before my first Passive House training,” he recalls, “so I wasn’t clear on the order of things or where to focus my priorities.”

Arguably, he couldn’t have chosen a more difficult project for trying an energy retrofit. His strategy was to apply Passive House design principles and construction details to integrate the drafty and aging building shell into a healthy live-work environment.

The loose-laid ashlar stone foundation underwent some repair work, and a vapor barrier was laid over the stone, followed by 2 in. of spray foam. Any water that comes in runs into a sump, and epoxy coating on the original concrete slab serves as a “cheap and cheerful vapor barrier,” says Avellino.

Fixing leaks in the roof required tearing off about 4 in. of existing tar—more than a century of roofing material—which created room for 3 in. of exterior polyiso rigid foam and dense-pack cellulose in the rafter bays.

The reservoir wall cladding meant that the dew point (always a moving target in a mixed-humid climate) and the risk of condensation were key considerations. The best approach would have been to put all the insulation on the exterior, but that wasn’t an option, given that the objective was to restore the historical facade. Plus, the zero-lot-line conditions meant they couldn’t extend the structure.

Instead, Avellino researched how to insulate the walls from the inside; the best research at the time advised closed-cell spray foam at a minimum of R-15 for climate zone 4A. It was the primary air and vapor barrier. Inboard of the spray foam, 1-5⁄8-in. light-gauge steel studs were added in lieu of the originally specified 2×3 wood studs for framing the cavities filled with dense-pack cellulose.

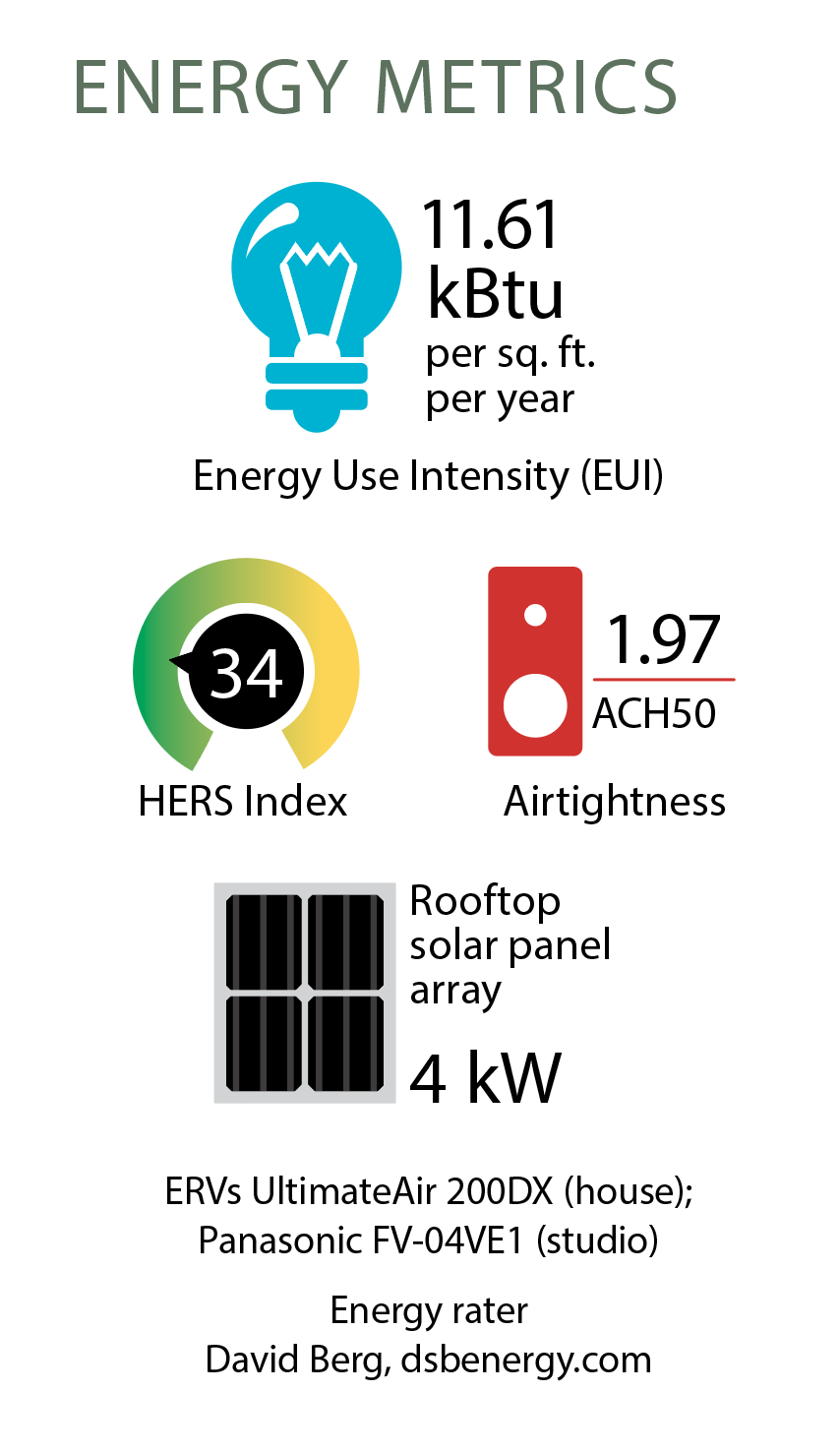

The nature of the building made airtightness challenging. Avellino admits he didn’t pay enough attention to the transition areas, and he has since seen spray foam fail as an effective long-term air barrier, particularly at assembly intersections. “There were gaps and cracks, and it’s why we couldn’t get below 2 ACH50, although that is still a great number for a retrofit,” he says.

For mechanicals, he spec’d ducted heat-pump heating and cooling in the residential spaces. His goal was to get the highest SEER (seasonal energy efficiency ratio) rating possible, but the mechanical contractor argued it was not worth the added cost. “I lost that battle,” Avellino confesses. “It could be more energy efficient. But we concentrated on sizing the system correctly and installing well-sealed ductwork.”

For ventilation, he used an UltimateAir ERV tied into the heating and cooling ductwork—the best he knew at the time. Today, he would duct those systems separately. For the photo studio he went with a Panasonic spot-ventilation HRV that is still functioning well. “It’s not at Passive House levels, but it’s doing its job,” Avellino says, noting that the homeowners have been continuously happy with the air quality.

Lessons learned

Today, he uses the foam-free approach that 475 High Performance Building Supply advises. On this building, he would now test the brick’s porosity to determine how much water it takes in, and perform a WUFI dynamic hygrothermal model to estimate the amount of insulation needed before condensation is an issue. He would not install spray foam as an impermeable vapor barrier (meaning that interior moisture can only dry inward and exterior moisture can only dry outward). Instead, he would furr out the interior walls with light wood framing—offset 1 in. from the interior plaster for a thermal break—filled with dense-pack cellulose with a smart, airtight, vapor-variable membrane as close to the interior as possible. He also allowed the originally specified wood studs to be swapped for light-gauge steel studs, without considering their potential for thermal bridging. Today, he would use dimensional lumber. He would likely spec the same roof assembly, with the addition of an airtight, vapor-variable membrane such as Pro Clima Intello Plus for both a vapor retarder and an air barrier.

On the energy front, Avellino hadn’t yet joined the all-electric movement. “It was gaining traction in my mind, as I was connecting the ills of hydraulic fracturing in my state with the use of natural gas in my home,” he says, noting that he has since embraced the push for all-electric energy and designs his projects accordingly.

In the case of Alvarez’s building, the range and the hot water are gas. “Knowing what I know now about the repercussions of fracking, I would heat pump everything with a combination of ducted and ductless minisplits.” In his climate zone, an ERV is the most suitable choice, rather than an HRV, which is more common in colder climates. To get what he calls “whisper quiet” CFMs, he concentrates on ductwork design and energy modeling, with input from engineers. Running a Manual J calculation to size the system correctly is his standard practice—as it was even back then. Interestingly, Alvarez’s system was still oversized because the mechanical contractor didn’t believe in the details of then envelope and its 2 ACH50 airtightness level.

Fishtown fabric

Avellino believes this project would not happen in today’s market. Instead, a developer would buy the lot and tear down the existing structure to replace it with production condos. And while he makes the point that there would have been nothing wrong with turning the building into multifamily housing, it would not be the same in terms of its architecture. Certainly, the envelope would not have undergone a retrofit that is near Passive House level.

In short, it’s special. Not everyone has the means to undertake such a renovation, and it doesn’t maximize the number of occupants to a lot, but it has another kind of value. As Avellino puts it, “This project acts as a reminder that even amidst economic prosperity, when building new is relatively easy, the city’s unique fabric is worth all efforts to preserve.”

From Fine Homebuilding #305

To view the entire article, please click the View PDF button below.

RELATED LINKS