How to Calculate Energy Costs

Learn about methods and formulas for determining how much energy appliances use.

Over the past dozen years of performing energy audits and assessments, I have learned there are three root causes that warrant an audit: 1. there is a problem with the house, 2. there is a problem with the equipment/appliances or, 3. a problem with the occupants. Often these problems require testing the electrical system and equipment to determine usage and associated costs. In this post, I’ll describe a few methods for determining how much cost is associated with electricity usage.

Key terminology

Voltage is the difference in electrical potential energy between two points per unit electric charge. More simply, it is a pressure that pushes charged electrons through an electrical wire or circuit, much like water pressure in a plumbing system. Almost all voltage in U.S. residential construction will be 120/240 volts. Often represented by the letter E for electromotive force.

Amperage is the strength of an electrical current, often referred as an amp. Amperage would be water flow as gallons per minute in our plumbing analogy. Devices such as breakers or fuses, and wire sizing are all based on the amperage of a circuit; 100- to 200-amp main electrical service panels are common sizes in residential construction and 15- or 20-amp branch circuits are common for lighting and plug loads. Current is represented by the letter I.

Wattage is the rate of work and is represented by the letter P. It’s a measurement of usage, much like tracking water use with a water meter. Wattage is the measurement of how electricity is billed and is the most useful electrical information to an energy auditor. Electricity is billed at a kilowatt hour (kWh), or 1000 watts used in an hour.

Resistance is a measure of the difficulty to pass an electrical current through a conductor. The concept is similar to friction and is measured in ohms. In plumbing, this would be like pushing water through a pipe—the smaller the pipe, the harder it is to push the water through. Resistance can be beneficial in a piece of electrical equipment, such as in electric resistance heating, but it can also be bad. For example, when too many amps are running through a wire that is too small for the load, the resistance can cause the wire to fail, possibly resulting in damaged equipment or a fire. I don’t commonly use the resistance measurement, but occasionally it is needed to calculate the cost of power. Resistance is represented by the letter R.

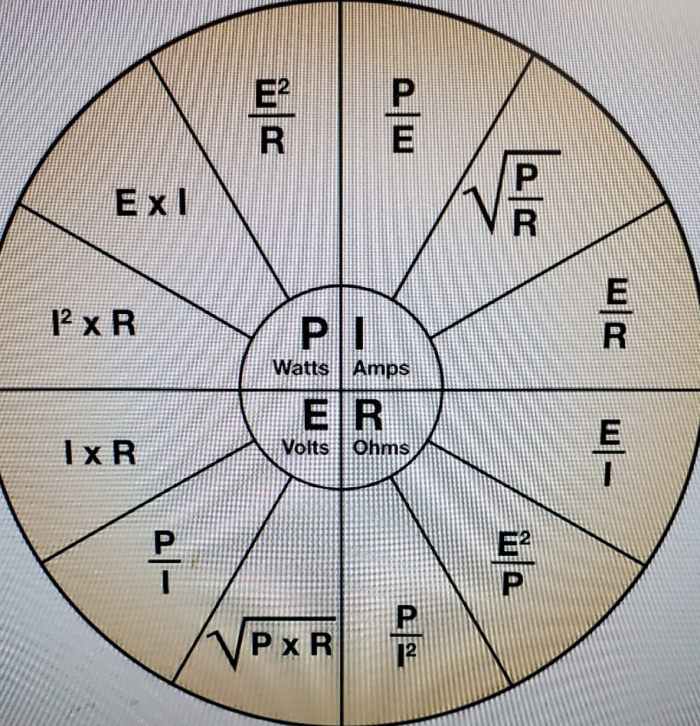

The Ohm formula

Now that we have some basic terminology to work with, let’s look at one of formulas needed to calculate the cost of power: Ohm’s Law. There is a direct relationship between the voltage, current, wattage, and resistance in every electrical circuit. These relationships are Ohm’s Law and can be shown in the following formulas: E÷I=R E÷R=I IxR=E P÷I=E P÷E=I IxE=P

Because I am almost always solving for P (the wattage used by a piece of equipment), the Ohm’s Law formula I use most is current (I) x voltage (E) = wattage (P).

To determine how much a piece of equipment costs to operate, another formula is needed. Electricity is billed in kilowatt hours or 1000-watt hour increments. Let’s use an electric space heater that consumes 1000 watts or 1 kilowatt as an example. One kilowatt hour (kWh) x the cost of electricity in a given area; for this example, let’s make the cost of electricity $.10 per kWh x the amount of time the device is operating = the cost of operation. So, assuming the electric space heater runs for 25 hours, the formula to calculate the cost is 1kWh x $.10 x 25 hours = $2.50.

A real-world example

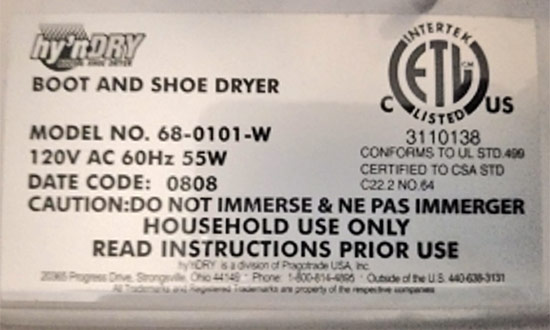

One way to determine how much an appliance or piece of equipment costs to operate is by reading its nameplate. Every modern electrical device will have a nameplate or tag listing the voltage at which the equipment is designed to operate, and either its amperage or wattage. These tags are on cord and plug devices as well as fixed equipment like water heaters and air conditioners; you just need to know where to look.

Because the power consumption is already listed as wattage, the calculation to determine the cost of operation is simplified. First, convert the 55 watts to kilowatts: 55 w ÷ 1000 = .055 kW. Using an electricity cost rate of $.10, this boot dryer will cost $.0055 per hour, providing the voltage is 120 Volts. The formula is .055 kWh x 1 hour x $.10 = $.0055 per hour—or a little more than half a penny per hour. Notice I said providing the voltage is 120 Volts; voltage can impact cost—more on that in a bit.

What if there isn’t a nameplate with information on a piece of equipment? Then we test. There are a couple ways to test; the first is with a plug-in watt meter. The one I use is called a Kill-A-Watt Meter. You can test almost any appliance that has a standard 120-volt plug. These meters will display the voltage at the electrical receptacle, as well as the current being drawn and the wattage. Some models can be programmed with electricity rates in your area and can record usage over a period of time. This information can then automatically calculate the costs associated with the appliance.

The toaster being tested was found to be drawing 7.05 amps and the voltage was 120 volts. This information helps to calculate the wattage using Ohm’s Law: Voltage x amperage = wattage. The appliance was using 846 watts.

Another way to test requires someone trained in working with electricity. This method involves an electrical box or service panel that is “live,” meaning the power is turned on, and there is a risk of electrocution. Using a clamp-on ammeter set to measure current, the power consumption of a circuit can be tested. I often use this method when testing devices, such as a well pump or furnace, that do not have a cord and plug connection.

It may also be beneficial to test an entire service panel. Clamping over each of the main power cables entering the service panel and adding the two together will show the usage of the entire panel at the time of the test. Again, this type of testing should only be conducted by someone trained in working with electricity.

Voltage impacts cost

I mentioned earlier that electricity costs can be affected by the voltage supplied to a home. This voltage “setting” is provided by the electricity supplier and is set at the transformer outside. Each phase or service conductor is typically set at 120 volts, but I have seen some transformers set in excess of 130 volts.

To calculate the impact of voltage on cost, we use a slightly different version of Ohm’s Law: P=E²÷R. This time, we need to solve for R (the resistance in the appliance). Again, using a 1000-watt space heater, which draws 8.33 amps at a listed voltage of 120 V, we will solve for R using the formula R=E÷I. That’s 120 volts ÷ 8.33 amps = 14.4 Ohms or resistance. The resistance of the space heater is a constant. Now solve for P, 120² volts ÷ 14.4 Ohms = 1000 watts. Now increase the voltage to 130, and the formula is 130² volts ÷ 14.4 Ohms = 1174 watts—an increase from $.10 per hour to $.1174 per hour. If this space heater were to run continuously, the increased cost would be $12.53 per month, just by an increase of 10 volts.

A word to the wise

Testing electrical equipment for usage and cost can be intimidating, and I don’t recommend messing around inside live electrical panels and devices unless you’ve had training. There are some good tools and products on the market to help monitor usage. Smart circuit breakers are available from Leviton—and likely from other manufacturers soon enough—that track electrical usage through the breaker. There are also monitoring products that can be installed on individual circuits or the main power cables that enter the home. Both may need to be installed by an electrician. Another alternative is through an electricity supplier; many use smart meters that have technology to record whole-house usage. Some utility meters can supply the information either daily or hourly, and some can track to the minute.

To many, electricity is a mystery, but calculating what a device costs to operate is just and matter of pulling information from the nameplate and doing some math. But, take it from an old electrician who has been “tickled” more than once by electricity—play it safe!

Originally published on GreenBuildingAdvisor.com.

Randy Williams is a residential energy auditor and builder in Grand Rapids, Minnesota. Photos courtesy of the author.