Timber-Framed Solar Canopies

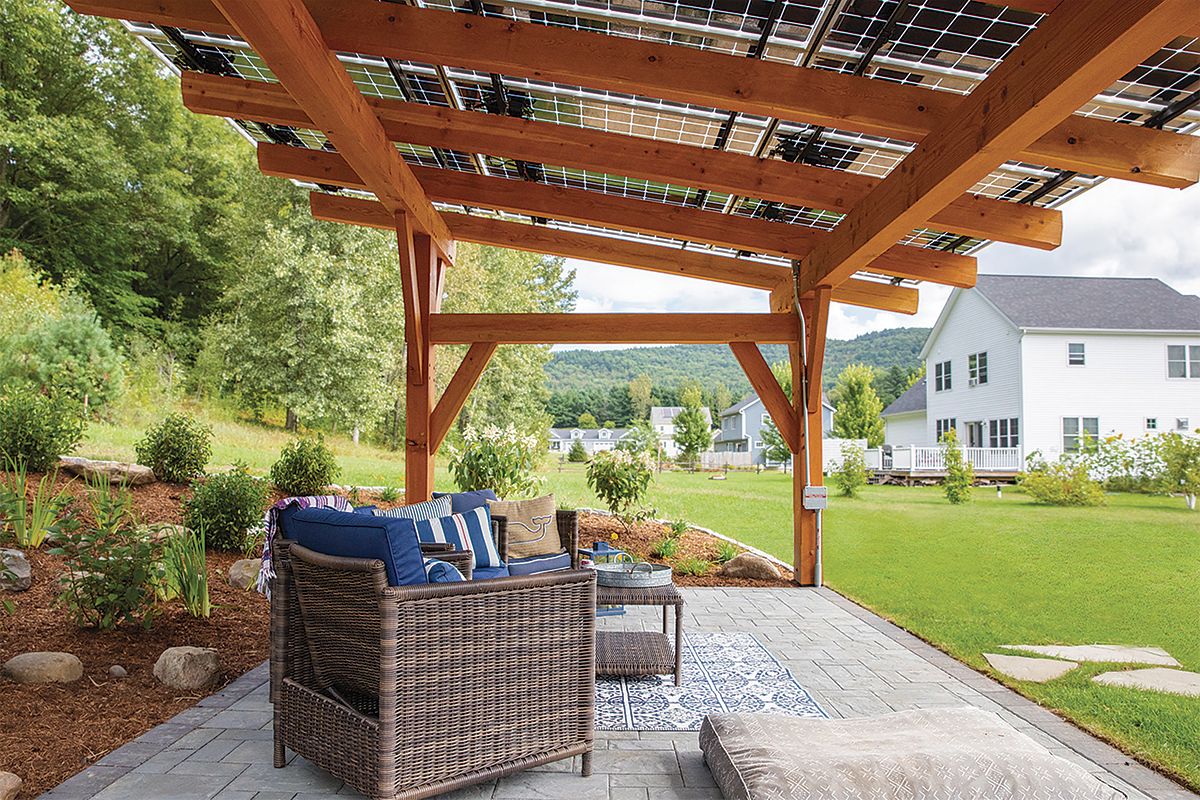

This creative approach to a ground-mounted PV array offers added functionality in one energy-producing package.

Synopsis: House orientation, roof penetrations, tree canopy coverage, and building restrictions can be obstacles to adding a solar array to a house. In situations like these, solar canopies offer an alternative. This article profiles one company that has partnered with a timber-frame and design company to bring solar power to houses that encounter such obstacles.

As more and more eco-minded homeowners consider ways to tap into renewable clean energy sources, on-site residential production gains appeal. Many choose to add solar arrays to their roofs; others opt for ground-mounted systems. But sometimes house orientation, roof penetrations like dormers and chimneys, tree canopy coverage, or building restrictions—as in the case of historic districts—mean subpar solar capture. Even if there is room on the property and orientation is optimal, ground mounts are often viewed as eyesores. Are there other options? Yes. Consider the timber-framed solar canopy.

SunCommon—a B Corp–certified company offering solar and other clean-energy solutions throughout Vermont and New York’s Hudson Valley region—debuted its timber-framed solar canopy in 2017. Solar canopies, which are structures topped with solar panels, can be used as carports (and EV-charging stations), patio coverings, woodsheds, and places to house large equipment and/or gardening tools and supplies, among other potential uses, all while generating energy. SunCommon has partnered with New Energy Works, an employee-owned timber-frame and design company based in New York and Oregon, to deliver timber-framed canopies in one complete energy-producing package. And the concept is catching on.

A multifaceted solution

SunCommon’s mission is to make residential energy generation accessible to more people. The company’s solar canopies can be the answer when a roof is disadvantageous to meeting energy demands, and the timber framing elevates the aesthetics of a conventional ground-mounted system. (The first iteration of the framing kit used whole timbers from WholeTrees Structures. Though beautiful, they were too niche, labor-intensive, and cost-prohibitive for customers.) Among the benefits of partnering with New Energy Works is that timber framing lends itself to production-style manufacturing, which is how these kits are produced—using computer numerical-controlled (CNC) machining with saws and routers.

It’s worth noting that a traditional carport doesn’t promise financial payback (apart from when the owner sells the property), whereas a carport with solar panels will help offset utility bills. Also notable is the fact that a solar canopy makes use of space that a ground-mounted system simply occupies.

Beyond the multiple functionalities and financial incentives, there is the potential for solar canopies to help move the needle on residential electrification—something both companies espouse. The team at New Energy Works views SunCommon’s structure as part of “a new era of smart solutions for power production and, by extension, electric cars.

Sustainable and scalable

Efficiencies in production reduce costs for both manufacturer and consumer, so replicability was key to the concept. SunCommon founder James Moore describes wanting “quick work in the shop” and a “predesigned program” to keep all processes as straightforward and economical as possible. Each frame is prefabricated and made of Forest Stewardship Council (FSC)–certified lumber from the Pacific Northwest; Douglas fir is used for its strength and its capacity to support long spans. (The original design accommodates two cars under a single bay.)

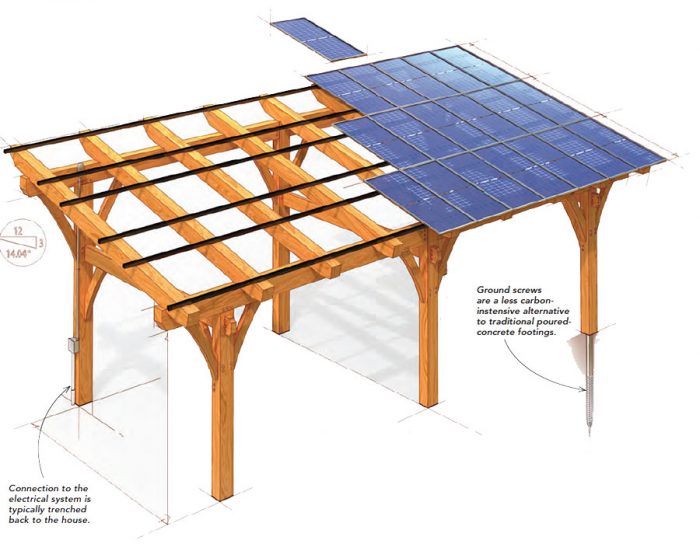

The foundation system can be installed on bare soil, turf, pavement, or gravel. It is fastened with 6-ft. ground screws, which eliminates concrete—both a financial and a carbon-emissions savings. Helical piers and poured footings have been used in the past and are still viable options, but flangeless, hot-dipped galvanized ground screws are SunCommon’s standard because they add to the ease of installation.

Asked to expand on why the ground-screw system is preferred, Moore says the objective was to minimize barriers to construction. Traditionally, foundations for post-and-beam structures have a footer under every post, with a tie-down at each location; this approach adds complexity, time, and money to the construction process. It also increases a project’s carbon footprint. “We looked at sustainability throughout when we were designing this product,” Moore notes. “We wanted to stay away from steel connections and concrete foundations.”

Owen MacDonald, timber-frame division manager for New Energy Works, notes the foundation type’s practicality: “One of the benefits of a ground-screw foundation is that it is something a GC can do on their own. The canopy kit is sent to them, and they can raise it themselves with rented equipment. Plus, for this size structure, ground-screw installation is faster than pouring concrete footings.”

Speaking from the builder’s standpoint, Tom Berry of SunCommon makes the point that the ground-screw system is easily repeatable and essentially turns the canopies into “solar mounting kits.”

The prefabricated framing means builders do not need to figure out new efficiencies each time they build, with the exception of a few minor changes depending on the solar company. (New Energy Works has brought the concept to West Coast–based solar installers to help them launch the product idea in that area of the country.)

Timber frame meets PV array

Moore delineates three aspects of a SunCommon solar canopy installation. First, there are the snow loads, wind loads, and seismic requirements for an engineer to calculate; Moore likens this to building an umbrella that will shed water off a roof with open sides, which means the accuracy of those calculations is critical for long-term durability. Second, there is the structural timber-framing, the design of which has some built-in flexibility to accommodate an individual solar installer’s panel-spacing schedule. In other words, the purlin system can vary to support arrays of different sizes and configurations. The third stage is the mounting of solar modules. (The roof pitch is fixed, meaning it can’t be changed to optimize solar collection based on latitude. Moore says doing so would impact the structural calculations and require further job-by-job engineering.)

The SunCommon canopy systems are larger than the typical roof system and don’t have the same required setbacks from roof edges or the complexities of dormers, chimneys, skylights, and vents to contend with. Their output is over 10kw. Moore has the same-size solar array on his roof as he does on his timber canopy, but the latter produces 10% more electricity over the course of a year. He credits the performance to the bifacial modules, which also produce power from the back side of the panel with exposure to reflected light. Plus, he says, they look great. The clear back sheet allows a small amount of sunlight to come through the spaces between the solar cells, making for a bright space beneath.

Shedding bulk water

When mounting a solar-panel system to a roof, bulk-water management strategies are already in place—the roof assembly has (ideally) been designed and detailed to divert water off and away from the house. As a freestanding structure, a solar canopy needs its own strategy. Moore’s design relies on a foam tape between the panels, which need some room to expand and contract with temperature changes.

The panels sit nearly flush with each other and are clamped into place for as tight a seal as possible, while still allowing for movement. After the initial installation, some clients have opted to add gutter strips beneath the panels at the horizontal seams, which is where water finds its way in. The gutters sit on top of the purlins; according to Moore, two 20-ft. to 24-ft. gutters along those seams move 99% of the water.

Asked why gutters are not standard with every kit, Moore explains, “Because then customers have the false expectation that this is intended to be a waterproof assembly. It’s not. There are things homeowners can do to manage the water further if they want that.”

Installing a canopy kit

Costs for SunCommon’s solar canopies range from $45,000 to $55,000 depending on size and site complexity. That’s for the entire system—foundation, timber framing, and solar and electrical installations. Anyone interested should investigate federal tax credits, which currently cover 30% of the total cost.

Interested homeowners can contact SunCommon for installation details. The company uses local contractors to erect the timber framing and to install the solar-panel system and electrical connections, which are typical for a solar installation. Care is taken with grounding using a string inverter. (Module-level inverter technology is rarely worth it.) Usually, installers can trench back to the house to tie into its electrical system.

Moore makes himself available to other solar installers looking to provide a similar product to their customers. “The bottom line is we need so much more solar power out there to solve our climate crisis,” he says. “We want to be supportive of other solar installers who are interested in this design. We share best practices and what we have learned over the years to bring beautiful solar to their neck of the woods too.

Timber frame meets solar array

The approach SunCommon has taken to the construction of its solar canopies allows for flexibility in sizing, which can be based on parking capacity or number of solar panels. For instance, the compact model includes 18 panels and fits one vehicle; the single fits 24 panels and two vehicles; and the double includes 42 panels and covers four vehicles.

Foundation options

The solar-canopy design is also flexible when it comes to the foundation, which can be helical piers, ground screws, or poured footings. Generally, site conditions and budget inform the foundation type. The go-to method is ground screws, which provide maximum flexibility, as they are better able to maneuver around underground obstructions and allow for ledge drilling. Helical piles are fast, easy, and cost-effective, and they have good pull-out strength. But if you hit a large rock they can’t handle, you’re out of luck. Poured footings are the most carbon-intensive and the most disruptive to the site.

Final thoughts

In recapping the solar canopy’s genesis, Moore shared an anecdote of his home’s roof solar array, which was not generating enough power after the family switched to electric vehicles. He wondered what “Solar 2.0” would be for a house with existing panels but now also heat pumps and EVs to power. The canopy was the answer.

SunCommon and New Energy Works have produced about 200 solar canopies as a team. To the product’s many attributes, Moore adds another: “This design turns solar power into a showpiece and gets people talking about it in a way they don’t usually.” In short, it’s cool and people like it.

—Kiley Jacques is senior editor at Green Building Advisor.

Photos by Patrick McCormack, courtesy of SunCommon, except where noted.

From Fine Homebuilding #316

RELATED STORIES