When Ductless Minisplits Make Sense

Easy-install, high-efficiency HVAC is ideal for retrofits and well-insulated new homes.

Synopsis: In this article, contributing writer Scott Gibson explains how this unique type of air-source heat pump works, how it differs from a conventional air-source heat pump, and in what conditions it performs at its best and its worst. A sidebar written by senior editor Andy Engel explains how heat pumps work.

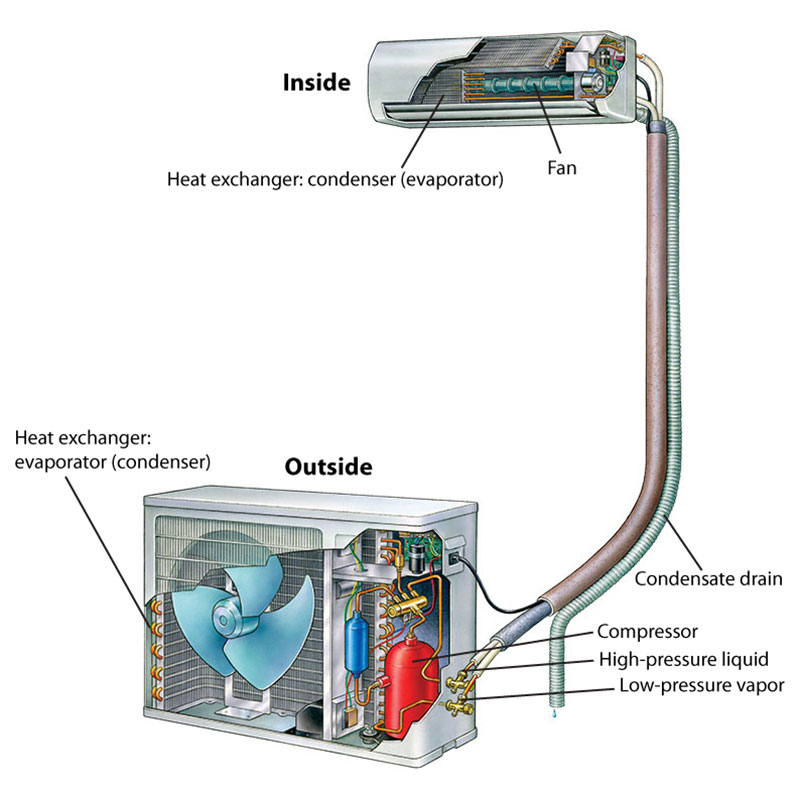

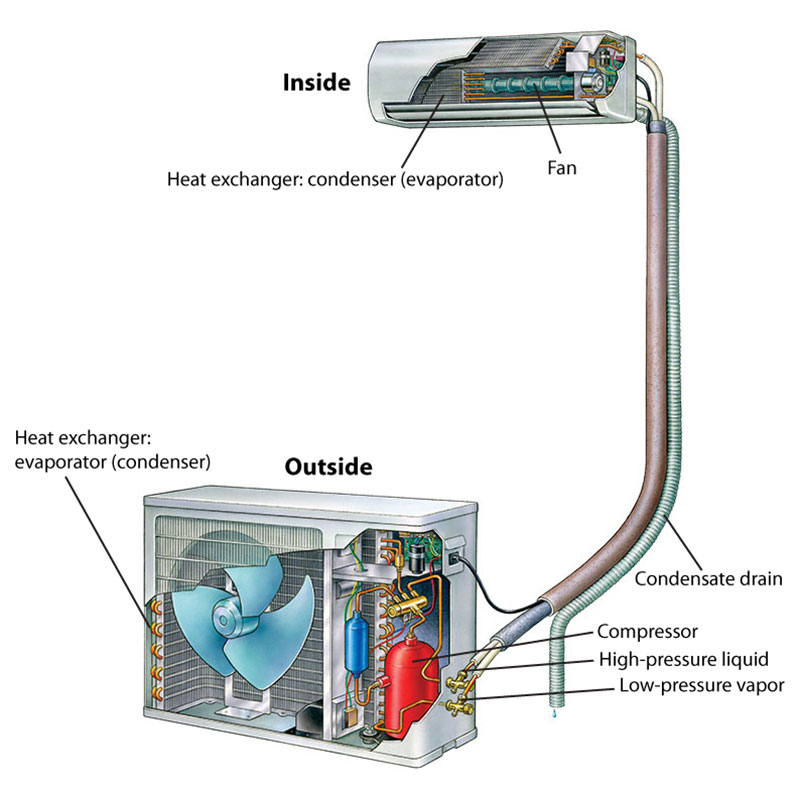

A minisplit consists of an exterior condenser and one to eight interior heat exchangers. Instead of sending conditioned air through a system of ducts, a ductless minisplit sends refrigerant through small-diameter supply lines in the walls to each heat exchanger, where a fan blows air over an evaporator to either heat or cool the space. Not only is it easier to retrofit most houses with a ductless system than a ducted one, but minisplit distribution losses are generally much less than those of a standard air-source heat pump. Although minisplits perform better in cold weather than standard air-source heat pumps, in a leaky, under-insulated house, they may not be able to produce enough heat in very cold temperatures. This can require supplemental heating and/or be an incentive for the homeowner to tighten up the envelope.

Widely used in other parts of the world, ductless-minisplit heat pumps (or minisplits) account for only about 5% of heating and cooling systems in the united States. Although minisplits are made by a number of companies, conventional air-source heat pumps are much more common. Despite that, minisplits are being promoted as a simple way to air-condition houses that lack central ductwork. That’s true as far as it goes, but to a growing number of builders specializing in high-performance houses, that’s just the beginning.

Like conventional air-source heat pumps, minisplits move heat from one place to another via refrigerant and insulated copper lines, using electricity for compressors and fans but not directly consuming any fuel to create heat for a building. In winter, a minisplit extracts heat from outdoor air and moves it inside. In summer, the process can be reversed so that the same equipment cools the house.

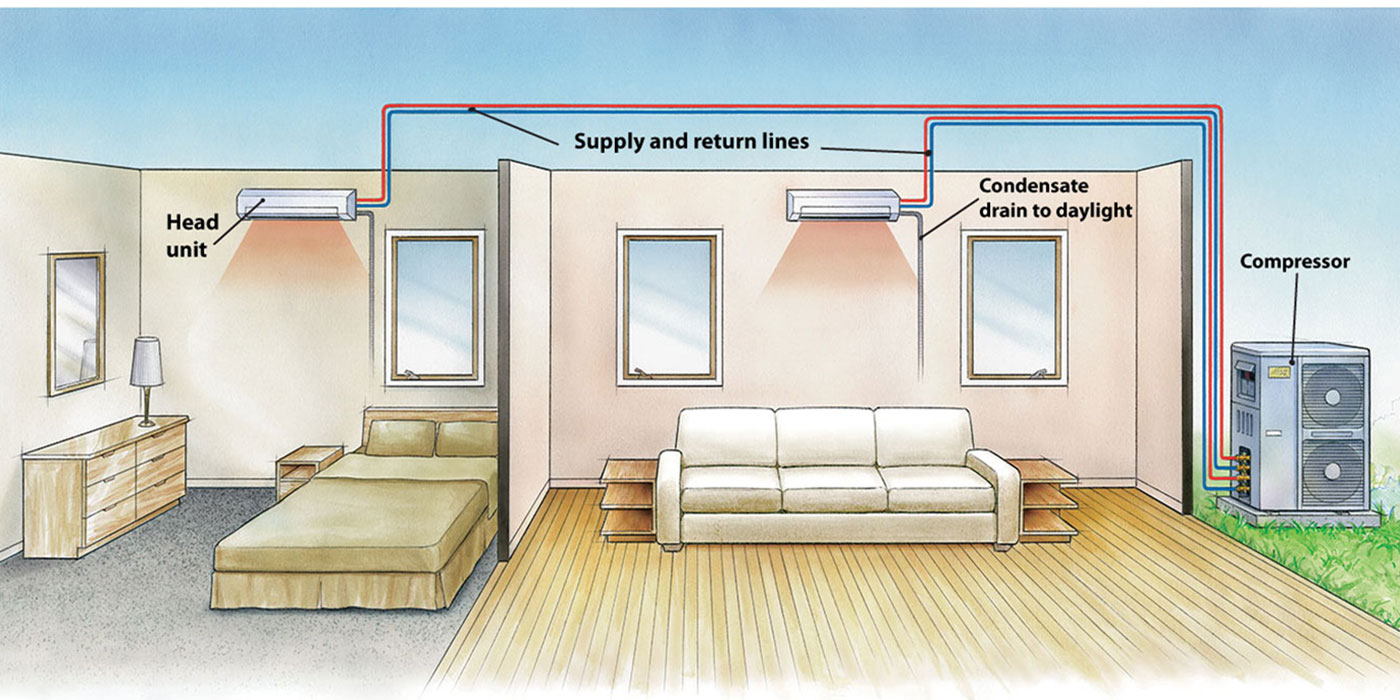

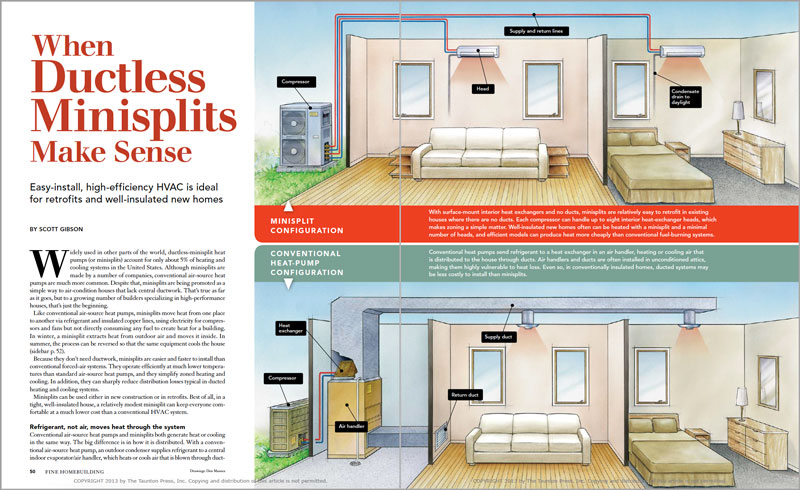

Minisplit configuration

With surface-mount interior heat exchangers and no ducts, minisplits are relatively easy to retrofit in existing houses where there are no ducts. Each compressor can handle up to eight interior heat-exchanger heads, which makes zoning a simple matter. Well-insulated new homes often can be heated with a minisplit and a minimal number of heads, and efficient models can produce heat more cheaply than conventional fuel-burning systems.

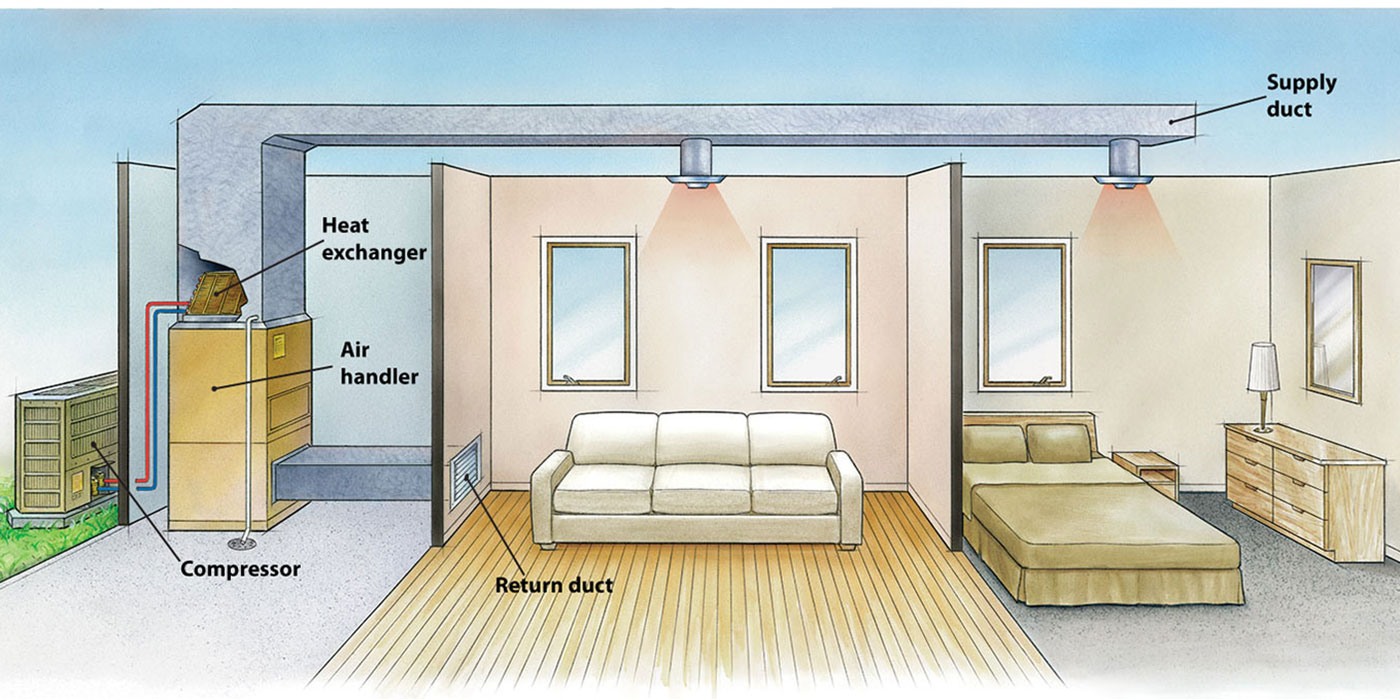

Conventional heat-pump configuration

Conventional heat pumps send refrigerant to a heat exchanger in an air handler, heating or cooling air that is distributed to the house through ducts. Air handlers and ducts are often installed in unconditioned attics, making them highly vulnerable to heat loss. Even so, in conventionally insulated homes, ducted systems may be less costly to install than minisplits.

Because they don’t need ductwork, minisplits are easier and faster to install than conventional forced-air systems. They operate efficiently at much lower temperatures than standard air-source heat pumps, and they simplify zoned heating and cooling. In addition, they can sharply reduce distribution losses typical in ducted heating and cooling systems.

Minisplits can be used either in new construction or in retrofits. Best of all, in a tight, well-insulated house, a relatively modest minisplit can keep everyone comfortable at a much lower cost than a conventional HVAC system.

How heat pumps work by Andy Engel

Heat pumps don’t make heat; they move it. They can move it from outside to inside for winter heat, or from inside to outside for summer cooling. To understand how that happens, keep these four principles in mind.

1. Even when it’s cold outside, there’s some heat in the air. Think about it this way: 20°F might be cold, but it’s warmer than minus 20°F. Until the temperature reaches absolute zero (minus 459.67°F), some heat is available.

2. Heat flows from warm to cold.

3. When the pressure of a gas increases, so does its temperature. This is why the lines to an air compressor’s tank get hot. The inverse is also true: When pressure drops, so does temperature. This is why ice forms when you pop the top of a really cold beer.

4. When liquid changes to gas (boils or evaporates), it absorbs heat. When gas changes to liquid (condenses), it gives up heat.

Heat pumps are closed systems filled with refrigerant, a fluid with a boiling point that’s typically around minus 40°F. In a heat pump, there is a low-pressure side where the refrigerant is cooler and a high-pressure side where the refrigerant is warmer. A compressor is used to pressurize the refrigerant, which raises its temperature. When pressurized refrigerant is allowed to expand, it cools down. The high- and low-pressure sides are joined with tubing (lines) and separated by an expansion valve that controls flow. The refrigerant runs through two separate heat exchangers: the evaporator and the condenser, which handle the low- and high-pressure sides respectively. Each heat exchanger can be either the evaporator or condenser depending on whether the system is in heating or cooling mode. One heat exchanger is located outside, and the other is inside. (In a minisplit system, there is an interior heat exchanger at each head.)

In heating mode, the low-pressure side is outdoors. If the outside air is warmer than the low-pressure refrigerant vapor (which might be at minus 40°F), heat flows from the outside air to the refrigerant at the heat exchanger, or evaporator. The heated refrigerant returns to the compressor, which pressurizes the vapor, warming it more. Now warmer than the air inside the house, the refrigerant flows to the indoor heat exchanger, or condenser. In the condenser, the refrigerant vapor condenses to a liquid, giving up the heat gained outside and warming the house. The cooled, now high-pressure liquid refrigerant passes through a thermal expansion valve. The valve meters the liquid refrigerant’s flow, reducing its pressure on the outlet side, which causes the refrigerant to vaporize and cool inside the evaporator, where the cycle begins again. In the summer, a reversing valve inverts the process, condensers and evaporators swap roles, and heat moves from inside to out.

—Andy Engel is a senior editor.

Refrigerant, not air, moves heat through the system

Conventional air-source heat pumps and minisplits both generate heat or cooling in the same way. The big difference is in how it is distributed. With a conventional air-source heat pump, an outdoor condenser supplies refrigerant to a central indoor evaporator/air handler, which heats or cools air that is blown through duct-work to individual rooms. With a ductless minisplit, one outdoor condenser supplies as many as eight individual indoor units (heads) with refrigerant through small-diameter supply lines. Each head contains a small evaporator and heats or cools by blowing air over the evaporator. When the system is being used for cooling, a drain carries condensation away from the head. Each indoor head can be controlled with its own thermostat, making it relatively simple to manage heating and cooling in different parts of the house.

Advantages of going ductless

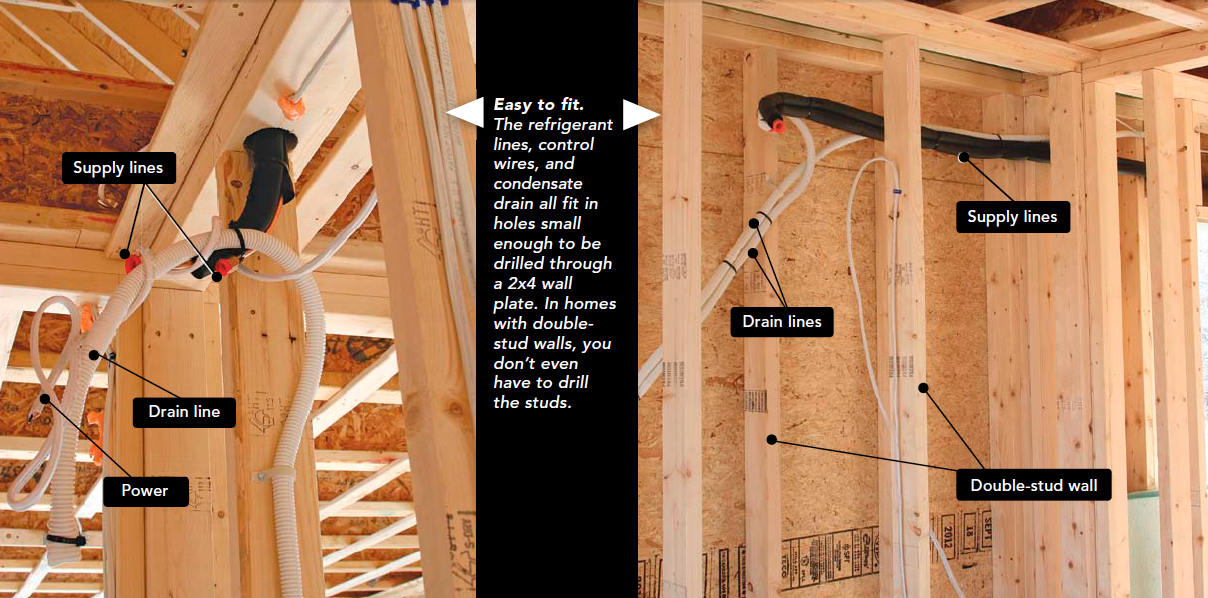

Eliminating ductwork simplifies installation, especially in a retrofit, where putting in ducts could be invasive and expensive. In a ductless system, refrigerant piping, control wires, and the condensate drain fit together through holes small enough to be drilled in a 2×4 wall plate. A simple system that includes a single outdoor compressor and a few indoor heads can be installed quickly, with few of the construction headaches associated with conventional heating and cooling. Ducts also are inherently wasteful, either because they’re leaky or because they lose energy as they pass through unconditioned areas such as attics or crawlspaces. The u.S. Department of Energy estimates that as much as 30% of the heating or cooling energy in a conventional duct system is waste.

Because the small-diameter refrigerant lines used in minisplit systems are insulated and don’t have as much surface area as air ducts, they lose much less energy. Energy loss with minisplit refrigerant lines is as low as 1% to 5%, according to the National Association of Home Builders Research Center.

The ductless part is obvious, but what about minisplit?According to Fujitsu, split means that the system has indoor and outdoor components. Traditional residential and commercial central airconditioning systems (which also are split) have capacities of 10 tons or more, which is the equivalent of 120,000 Btu per hour. Mini splits are simply smaller, with capacities of as little as 7000 Btu, Fujitsu says—hence, ductless minisplit. Mitsubishi Electric, however, doesn’t like that term. “We prefer not to use the term minisplit, as it has been shown to cheapen the perceived value of our systems, instead favoring ductless systems or ductless split systems,” the company said in a written statement. “We currently offer residential systems up to 4 tons [48,000 Btu] that can cover as many as eight rooms or zones from a single outdoor unit.” |

Minisplits can heat in cold temperatures

The inability of most conventional air-source heat pumps to operate efficiently in cold weather is one reason they are generally limited to moderate climates. As temperatures fall into the 40s, supplemental heating is usually needed to keep indoor-air temperatures comfortable. The supplement might take the form of electrical-resistance coils in the air handler, or a gas- or oil-fired furnace that kicks on when it’s too cold for the heat pump to work. Many minisplit models, however, continue to produce heat even when the outdoor temperature drops below zero. Mitsubishi says its Hyper-Heat models work at 13 below zero, although at reduced efficiency.

Jim Godbot of Jim Godbot Plumbing and Heating in Biddeford, Maine, had one customer call him up on a windy, 20-below day to say how comfortable his minisplit-heated house was. One potential disadvantage is that unlike most conventional airsource heat pumps, minisplits don’t have any supplemental heating capacity. In superinsulated houses with low air leakage, this isn’t a problem. In drafty, underinsulated houses in snow country, more powerful supplemental heat is needed. If the house is in an area where temperatures fall below the minisplit’s capacity for extended periods, that secondary heat source would have to be able to handle the entire heating load.

Measuring efficiency can be tough

While minisplits can provide heat in very cold weather, efficiency drops as the outdoor temperature goes down. The National Renewable Energy Laboratory (NREL) says that measuring the efficiency of these systems, which it calls MSHPs (minisplit heat pumps), is challenging, in part because of their variable-speed components.

“Most public information on MSHP performance is provided by equipment manufacturers, and is typically limited to performance at a single operating speed for heating and cooling,” says NREL’s summary of a research paper on the topic.

NREL researchers developed testing strategies allowing them to measure the performance of two ductless-minisplit installations across a wide range of operating conditions.

“In the laboratory tests,” the NREL report says, “researchers found that both MSHPs achieved manufacturer-reported performance at rating conditions. However, at other temperature and humidity conditions, the heat pumps’ capacity ranged from 40% above to 54% below the manufacturer-reported values. Knowing how performance varies is critical in order to reasonably estimate annual energy consumption of an MSHP and to compare MSHPs to other heating and cooling options. Minisplit heat-pump efficiency [measured as coefficient of performance, or COP] was seen to significantly exceed rated efficiency at low compressor speeds—a very important effect.”

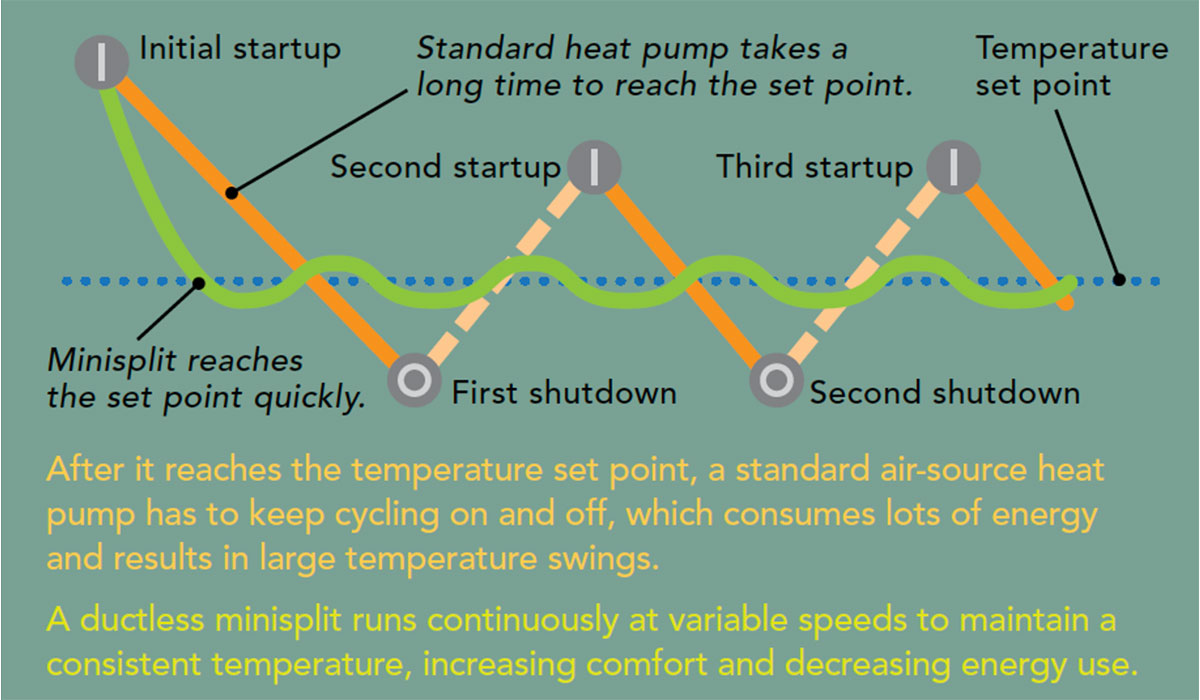

The tests suggest that variable-speed fans and compressors in ductless minisplits are more energy efficient than the simple on-off cycling of standard air-source heat pumps and are an important factor in minisplits’ improved performance. According to NREL, “Two-stage forced-air systems must cycle on and off at loads below the low-stage cooling capacity. MSHPs can reduce the compressor speed to meet low cooling loads and have higher COPs under such conditions.”

COP is an important measure of system efficiency, although not the only benchmark for heating and cooling equipment. It is the ratio of energy input to heating or cooling energy output. The higher the number, the more energy efficient the device. For example, if a minisplit consumed 1 unit of energy to put out 5 units of energy, the COP would be 5. NREL’s tests found that COPs ranged from roughly 7 at an outdoor temperature of 55°F to a COP of 2 or less as outdoor temperatures fell to 5 below zero.

A useful guide to equipment efficiency is the directory of product performance available at the Air-Conditioning, Heating, and Refrigeration Institute’s website (ahridirectory.org).

Wall-mounted units are typical

Indoor units often are mounted on a wall close to the ceiling, and that makes them much more visible than other heat distribution systems. For those who object to the looks, other options show only a flat grille when installed. However, cutting into the house to install them negates some of the low-installation-impact advantages that ductless minisplits advertise in the first place.

Another consideration is the exterior conduits that connect the compressor with interior air handlers. In new construction, supply lines can be buried inside walls, but the easiest way to install a system in an existing house is to run a line up the outside of the house, to bore a hole through the wall, and to attach wiring and refrigeration lines to the indoor unit. Although manufacturers offer paintable covers that disguise the lines, they can’t be hidden completely.

On the plus side, a compressor can be as much as 100 ft. away from an air handler, allowing it to be tucked on the back side of the house and mostly out of sight.

Do minisplits save money? It depends

Ductless minisplits can be a less expensive heating and cooling option than conventional HVAC equipment, especially in a high-performance house with reduced heating and cooling loads. A ductless system could be installed at a fraction of the cost of a groundsource heat pump, for example.

The National Association of Home Builders Research Center says the cost of installing a ductless minisplit has dropped as the technology has become more established. Of course, relative costs depend to a large degree on what you’re comparing the minisplit to. Cost comparisons between ductless minisplits and other heating and cooling options are affected by the size and complexity of the installation, the heating and cooling loads, and whether the system is in new construction or a retrofit. With retrofits, the presence of existing ducts might make a traditional heat pump or air conditioner cheaper than a minisplit. Conversely, the cost of installing ducts in an existing house might make a minisplit system cheaper.

“The cost of ductless systems varies greatly depending on the application, size, zones covered, etc.,” Mitsubishi Electric says. “While the units themselves are sometimes higher priced, the labor and installation component can be significantly less for ductless systems, and they will provide significant ongoing monthly savings.”

Better low-temperature performance

Why do most ductless minisplits operate so much more efficiently than standard airsource heat pumps at low temperatures? They use inverter technology. An inverter converts alternating current to direct current, allowing the use

of variable-speed compressors and fans rather than standard heat-pump components that are either on or off. (Inverter technology is now finding its way into ducted systems.)

“By operating at higher rpm than traditional systems, our inverter-driven compressors ramp up quickly to provide instant warmth,” Mitsubishi says. “Once the desired set point is reached, the system slows down to maintain the perfect temperature.” A standard air-source heat pump, Mitsubishi adds, powers up more slowly, overshoots the desired temperature, and then shuts off. The building cools; then the cycle repeats, resulting in a broader temperature swing. In short, inverter technology allows the system to adjust its performance to match the demand for heating (or cooling) more closely. Additionally, variable-speed fans and compressors allow Mitsubishi’s minisplits to operate at 100% capacity down to 5°F, while a standard heat pump operates at only 60% of capacity at 17°F.

Operating costs on the heating side can be a big advantage. In a blog post written for Green Building Advisor, engineer and energy consultant Marc Rosenbaum says that heating costs for his house on Martha’s Vineyard in Massachusetts have run about $250 a year. He estimates that was one-quarter what it would have cost to heat with oil, which is typical in the region. Similarly, Jim Godbot says that he has installed several minisplit systems for air-conditioning in existing houses but found that the homeowners ended up using them for heat heat as well because they were cheaper to run than their existing gas- or oil-fired systems.

Rosenbaum also likes minisplits for three other reasons: variablespeed components that increase efficiency, the ease of zoning a house because each head’s output is controlled with an individual thermostat, and the smaller drop-off in capacity at lower outdoor temperatures when compared to conventional air-source heat pumps.

He also adds a footnote to the cost discussion: The difference in cost between 2-ton and 4-ton minisplit systems is “significant,” while the cost difference between an 80,000 Btu/hour furnace and a 120,000 Btu/hour furnace is not. That means money spent on insulation, good-quality windows, and air-sealing may leverage the use of a smaller, less expensive minisplit system.

Massachusetts builder Carter Scott has used ductless minisplits in his net-zero-energy designs. A ductless minisplit system with one head on each floor cost about $5000 and was enough to heat a twostory house he built in 2008. In similar designs, the upstairs head wasn’t needed unless temperatures dropped below 20°F.

Minisplits are plug and play

Conventional ducted systems are prone to a variety of installation errors and oversights. As a result, forced-air systems often must be tested and adjusted, or “commissioned,” after installation so that they perform as designed.

Rosenbaum says there’s no need for that extra step with a ductless minisplit. “I can tell you what we haven’t been doing: We haven’t been commissioning our buildings with ductless minisplits,” Rosenbaum writes. “If the building has a system with a lot of zones and a central controller, there may be some training from the rep, but no commissioning. These are self-contained products, so you are buying the control system with the unit. It’s all packaged.”

– Scott Gibson is a contributing writer.

Photos by Andy Engel, except where noted.

From Fine Homebuilding #237

To view the entire article, please click the View PDF button below.

View Comments

Excellent article! I live in Phoenix, it is 114 today and I am trying to cool the upstairs. How effective are mini splits on the cooling side of the house?