A Crown-Mold Concrete Mantel

A stock crown profile and quarter-round form the mold for an inexpensive and unique fireplace surround.

Synopsis: When he was getting ready to make a fireplace surround for his living room, special-issues editor Charles Miller went with a nontraditional choice: concrete. That material fit the requirements he’d outlined: It could be shaped to reflect the other trim details in the room; it was affordable (less than $30 in materials for the mantel and two pilasters); and it was fireproof. Miller attached the mantel and pilasters to the wall framing with 6-in. TimberLok screws. The mantel does not rest directly on the pilasters. To make sure the concrete work would match the room, Miller built molds with shapes that would relate to the rest of the room. To ensure easy disassembly of the concrete parts, he coated the mold surfaces with slippery housewrap tape. The concrete is ready-mix, with no additives.

I had three goals in mind when I started designing our living room’s fireplace surround. First, it had to reflect the other trim details in the room; second, it had to be affordable; and third, it had to be unmistakably fireproof. Concrete seemed like the clear choice, giving me a good excuse to put together a small-scale concrete pour. I really like this kind of low-anxiety concrete project. It’s devoid of the handwringing scenarios that often accompany a visit by the transit-mix truck, and you can’t beat the price tag. The mantel and both pilasters cost less than $30 in materials.

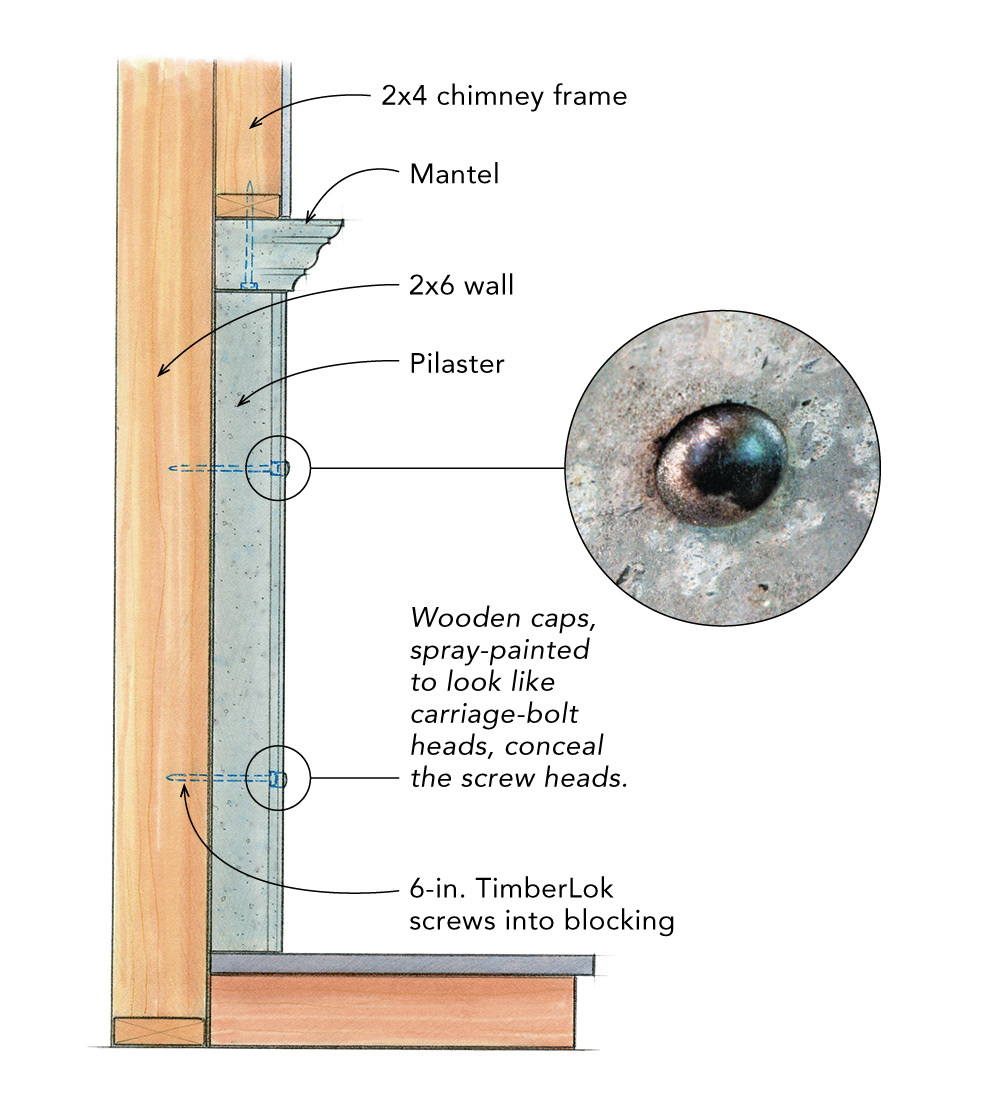

Fastening the surround to the wall

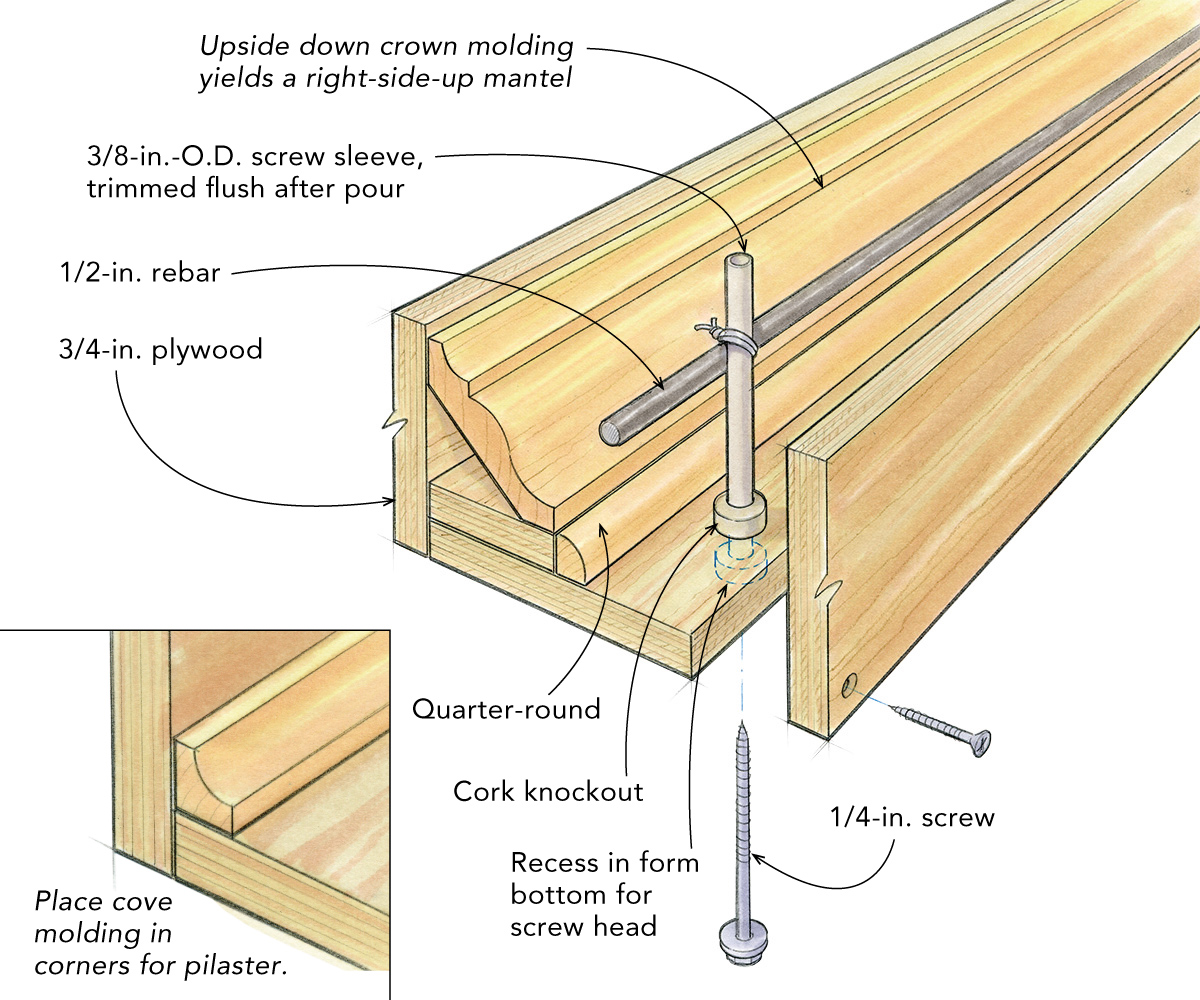

I used long screws to secure both the mantel and the pilasters to the wall framing. As shown in the section drawing, the mantel hangs from the chimney-shaped framing by way of two 6-in. TimberLok screws. The pilasters are screwed to blocking in the walls. The screw heads are concealed by spray-painted wooden caps that look like carriage-bolt heads. Although the pilasters appear to be supporting the mantel, there is actually a 1/16-in. gap between them.

After making the molds for both the mantel and the pilasters out of 3/4-in. plywood, I lined them with moldings that relate to the trim in the rest of the room. For easy disassembly, I applied some slippery polypropylene housewrap tape to all the surfaces that would come in contact with the wet concrete. When I unscrewed the form, the pieces just fell away from the mantel. The resulting surface was a little too shiny for my taste, so I wire-brushed the green concrete to give it a matte finish.

The mantel and both pilasters cost less than $30 in materials

I lined the pilaster form with good ol’ blue masking tape, and it worked just as well as the slippery red stuff. To vibrate the wet concrete into the nooks and crannies of the form, I held the foot of a bladeless reciprocating saw to the sides of the form. (A video in the Fine Homebuilding There’s a Better Way series shows how to do this step.) The concrete is garden-variety ready mix, with no additives.

I covered the filled forms with plastic sheeting, and then kept them covered for five days before unscrewing them. I made sure they were nice and wet by spraying them with water every day. This helped the concrete to cure properly so that it would achieve full strength and minimize cracks.

Photos by the author

From FineHomebuilding #221

To view the entire article, please click the View PDF button below.