Baseboard Done Better

A veteran carpenter shows how to achieve first-class results with timesaving techniques running baseboard.

Synopsis: Think you know everything there is to know about running baseboard? Read Gary Katz’s article on the topic and you’re sure to pick up some great tips, no matter what your skill level. This must-read article shows how to streamline measuring and cutting, and just wait until you see the tip on coping a corner without breaking off that pesky little sliver at the top.

Carpenters new to finish work often cut their teeth on baseboard, and for good reason. Baseboard has many of the basic joints that form the foundation for trim carpentry. Over the years, I’ve shown a lot of carpenters better ways to run baseboard. Whether you’re a veteran or new to the task, I’ll share some tips that will improve both the speed and the quality of your trim work.

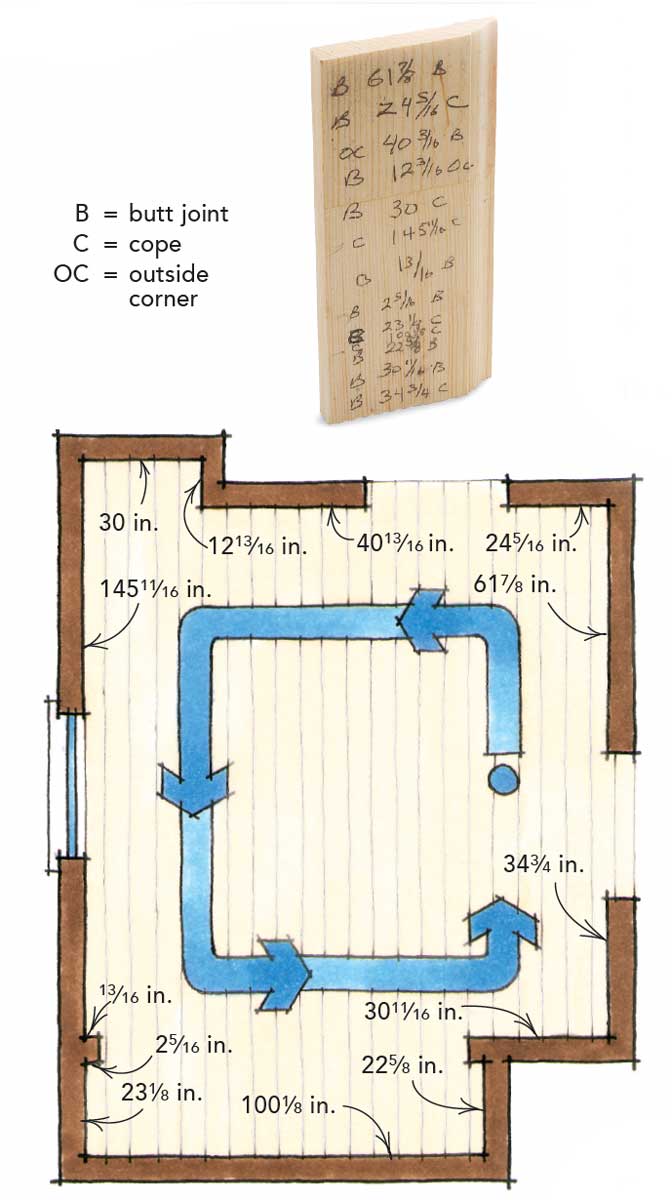

Measure once, measure precisely

The first key to installing any trim, especially baseboard, is recording accurate measurements on a cutlist. After years of practice, I’ve learned how to read a measurement when the tape is bent into a corner. But there are several other ways to measure precisely. One method is with a measuring block. For the block, cut a piece of baseboard to an exact length that’s easy to remember and add (4 in. is the length I normally use). Stick the block at one end of a run, measure to it, and add the length of the block.

For measuring to the eased edge of casing, simply lay the block flat and take a precise measurement to the crisp edge of the block. The same strategy works for an outside corner, but make sure to check the angle with a protractor to ensure that the cuts will leave you with a tight joint.

My rules for measuring change slightly depending on the length of the piece. For pieces longer than 6 ft., add about 1/8 in. so that you can spring the piece into place for a tight fit. For pieces shorter than 6 in., subtract a little so that the piece slips in easily between the casing and the corner. For everything else, measure precisely to the nearest 1/32 in.

Measure each length preciselyAccurate measurements translate to tightly fitting trim. If you’re not comfortable reading a tape measure bent into a corner, the techniques shown here yield exact dimensions.

|

Cutting corners made easy

Once you’ve recorded all your measurements on a cutlist, it’s time to head for the miter saw, which, by the way, should never be on the floor. Working on a stand with support for the work on each side of the saw is more efficient and more accurate. Many commercial stands have built-in wings, or you can go for a homemade version. Whatever the strategy, the wings should support the work so that it stays flat on the saw. I also attach a straight, flat auxiliary fence to the saw. This added fence supports the trim as it’s being cut and serves as a measuring aid, too. Make the auxiliary fence the maximum height your saw will cut, or at least as tall as the trim you’re cutting and slightly longer than the fence on the saw.

You made the cutlist so that you don’t have to visualize the joints as you cut them. Now it’s important to teach yourself which way to swing the head of the saw to make a cut for a corner. Instead of visualizing the joint or the location of the baseboard, you can memorize

two simple rules: For inside corners, the long point is always against the wall and the fence; and for outside corners, the short point is always against the wall and the fence. Armed with these two rules and the cutlist, you’re ready to start cutting.

The cutlist shorthand shortcutWhether it’s printed on paper or on a scrap piece of wood, an accurate cutlist is the work order you take to your chopsaw. Start at a door and work around the room counterclockwise, recording the measurement for each piece and the type of joint for each end. If possible, keep most of the copes on your right side for easier right-handed cutting. |

The fence helps with measuring

Measuring from the butt end of a board is easy. After making a square cut, lay the board flat on the saw table, and hook the tape on the end. Laying the board flat minimizes the chance that the end of the tape will slip off.

Measuring for an inside-corner cut is also simple. Make the 45° mitered cut for the coped end first. Again lay the board flat and face down, and this time, hook your tape measure on the long point of the cut.

For measuring outside-corner cuts, I put the auxiliary fence to use. Instead of “burning an inch” (measuring from the 1-in. mark), align the short point of the cut with the end of the saw fence, and pull the measurement from the edge of the fence. I spring-clamp longer pieces to the fence before measuring, or I flush the short point with the end of the extension wing, then hook my tape on the extension wing to pull the measurement.

I always use a sharp 25⁄10 pencil to mark measurements. The harder lead keeps the pencil sharper longer, and crisp, clean lines are essential for accurate cutting.

Measure and cut the stockThe next step in precise trim installation is transferring the numbers from the cutlist to the stock. An auxiliary fence on the chopsaw comes in handy at this stage.

|

Controlled cuts

You’re finally ready to cut. Just align the blade on the line and cut away, right? Wrong! It’s imperative that the blade cut exactly at the line, and absolute control of the material and saw is the only way to ensure an accurate cut.

To control the material, keep your free hand locked behind the auxiliary saw fence, with your thumb over the material. Begin the cut with the measurement mark 1⁄8 in. or so away from the blade. Now raise the blade, and using your thumb as a micro-adjuster, slide the material over slightly and let the blade enter the material again. Repeat the process until the blade is exactly at the line, and only then cut through the piece.

A jigsaw makes the best copes

Here’s where I generate all those nasty letters to the editor: Coped corners are faster and more accurate than miters (45° angle cuts on both pieces). For a crisp joint line, miters have to line up exactly in a corner. If the coped piece is off plumb slightly or not quite square to its neighbor, it’s harder to detect. The extra couple of minutes needed to cope more than makes up for the fussing that most miters require for a good-looking fit.

I still use a coping saw if I’m installing only a piece or two. The key thing you have to remember when using a coping saw is to keep the sawblade moving. Don’t try to cut quickly, and don’t push too hard on the blade. Instead, move the saw at a comfortable machinelike rate that you can maintain throughout the entire cut.

I’ve recently switched to using a jigsaw for copes, but it’s equipped with a Collins Coping Foot (888-838-8988; www.collinstool.com). The coping foot replaces the base, or table, of a jigsaw, and its shape allows you to follow the profile of a molding from the back side of the material while keeping the saw base in contact with the material.

Be sure to use the right blade with the jigsaw. Collins recommends a Bosch 244D blade (877-267-2499; www.boschtools.com). With only 6 teeth per inch and deep gullets, the blade cuts aggressively and clears the kerf of waste quickly. The teeth also have a wide set, so the blade cuts a wide kerf, which allows you to scroll-cut almost any profile. The wide set of the teeth means you also can remove material with the side of the blade to tune the cope.

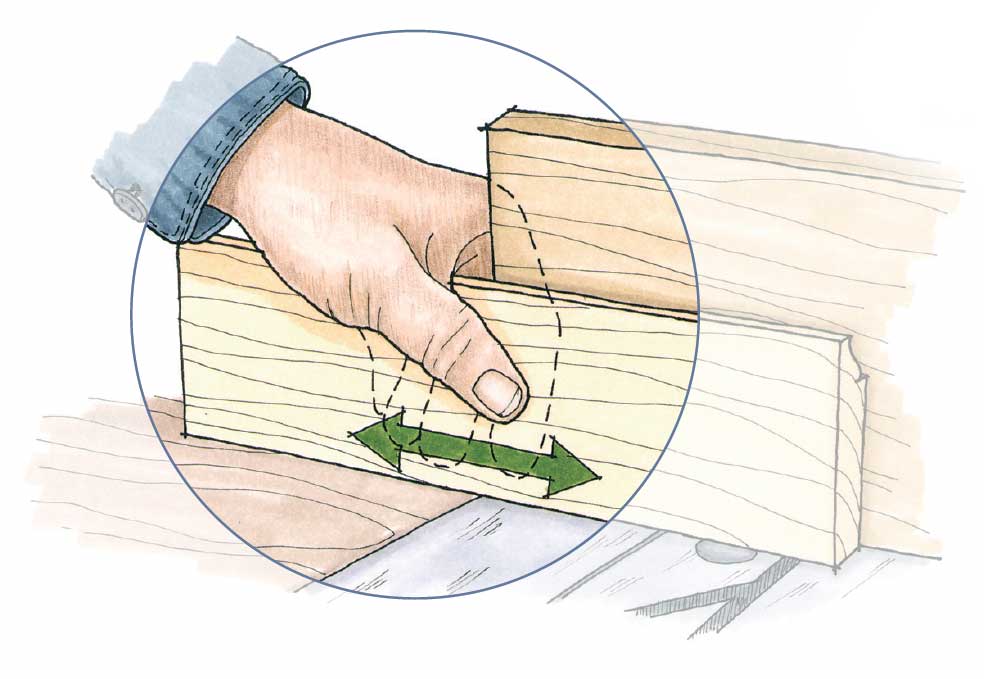

The step-by-step process of coping with a jigsaw is much better illustrated visually. In simplest terms, secure the board, and begin the cope with a series of relief cuts at critical points on the profile. For the colonial baseboard pictured here, I made two cuts. I first cut the sliver that forms the miter at the top of the intersecting pieces—the one that always breaks off before you can get the board nailed in. (I don’t make those little slivers wafer thin anymore. Instead, I leave them at least 1⁄8 in. thick, and then I mortise the intersecting piece of baseboard to accept the overlapping sliver, as you’ll see in the next section).

The second cut is to the point where the plinth, or the flat section of the baseboard, meets the curved profile. After making the relief cuts, it’s just a matter of following the profile with the saw held at a slight angle to create a back bevel.

Coping with a jigsaw

|

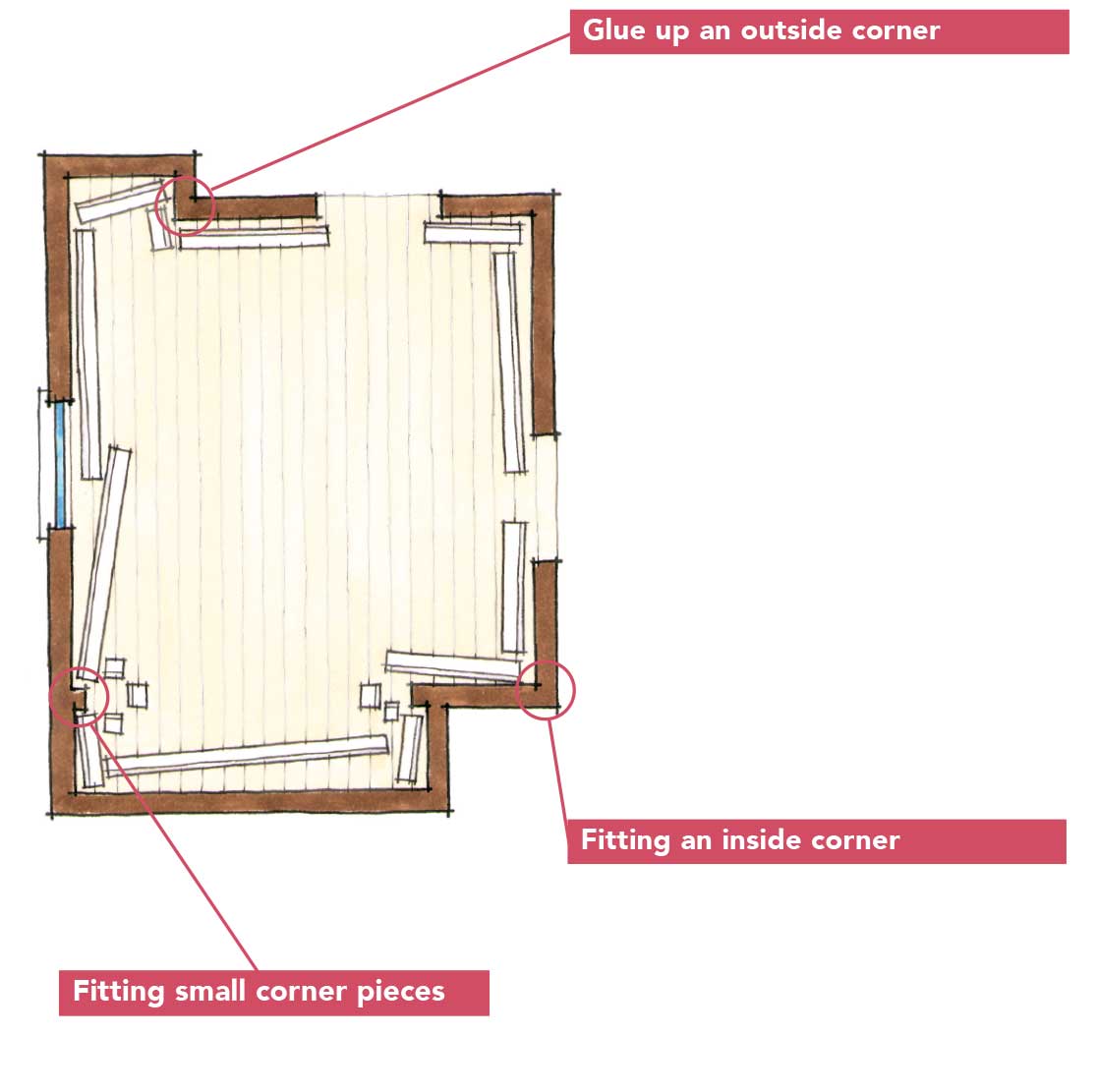

Installation is the easy part

After you’ve run through your list, and cut and coped every piece, spread the pieces around the room close to where they’re going. I generally install baseboard in the same order that I measured and cut it, except that I insert any small pieces (up to about 2 in. wide) first, such as between casing and a corner. Don’t try to nail these small pieces, or they’ll split. Instead, let the intersecting board hold them in place.

For this type of baseboard, which is only 31⁄2 in. tall, don’t bother trying to locate the studs. The wall plate is usually high enough for me to hit with 21⁄2-in. finish nails. For those areas where I need to nail higher, I simply find a stud with a magnet.

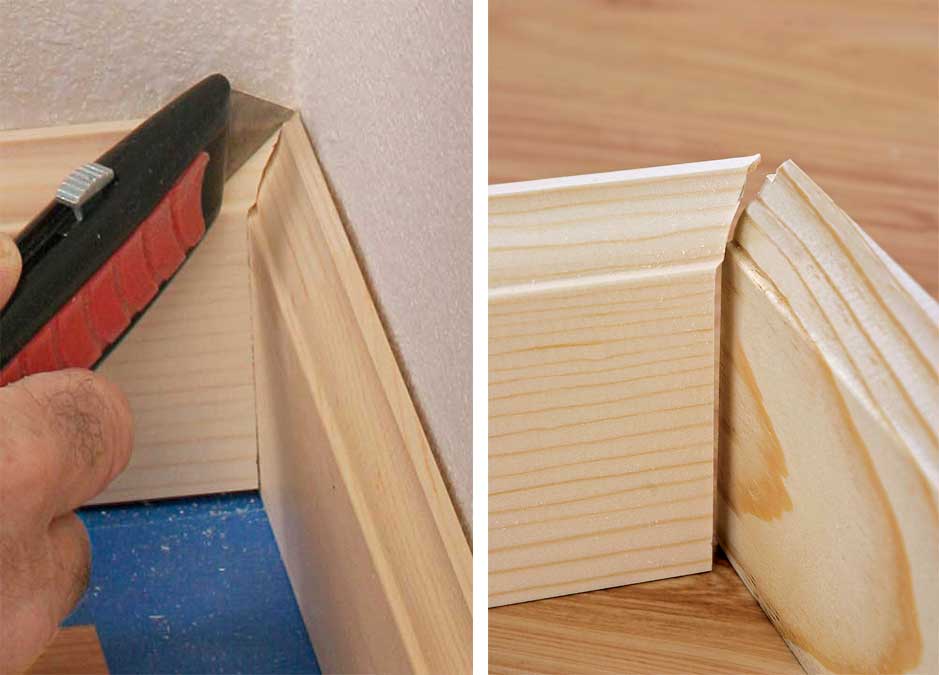

In a coped corner, always install the butt end piece first. Then slip in the coped piece. Pressing the coped piece tightly to the wall, plunge the blade of a utility knife into the top of the butt end using the edge of the miter cut as a guide. Remove the coped piece, and cut a notch deep enough to accept the overlapping sliver on the coped end.

Now the coped piece can go in permanently. If your copes are accurate, the fit will be tight. Tap the butt end of the coped piece with a block and hammer until the two pieces marry tightly in the corner and the butt end of the coped piece slips into position.

For outside corners, always test-fit the pieces before nailing them in. When you’re satisfied with the joint, apply glue to the mating surfaces of both pieces. Wipe off the excess glue, taking care not to get glue on the baseboard’s finished face. The glue joins the two pieces and also seals the ends of the boards. For stain-grade installations, sealing keeps the ends from absorbing more stain and

becoming darker than the rest of the board. I preassemble outside-corner joints using a 23-ga. pin nailer that leaves almost invisible nail holes. Then I nail the whole assembly into place.

Install the pieces in orderSpread the cut pieces around the room close to where they will be going. Then work around the room in roughly the same order that you took the measurements. For inside corners, always install the square-cut or butt-end corner pieces first.      |

Keep baseboard straight when the walls aren’t

As you can see from my cutlist, I sometimes like to cope both ends of longer pieces. With the little bit of extra length I give them, they spring into place with tight pressure-fit joints at both ends.

Most carpenters I know just nail the board tight to the wall. If there are any bows or bellies in the wall, though, making a piece of trim conform to them only accents the flaws. It’s a good idea to check long pieces with a string before nailing them in. Shim the baseboard so that it looks straight to the eye, then caulk any gaps between the top and the wall. The straight baseboard will make a crooked wall look straighter.

Preassemble all short sections, such as around a column, around an end wall, or for a drywall return at a door opening. Again, if the two sides aren’t square to each other, installing an out-of-square joint just makes the return look worse. Instead, make the joint square, shim the short piece, and caulk the top edge.

Finally, in areas where drywall is broken or missing, insert a drywall screw to keep the baseboard straight and plumb. Simply adjust the screw until the head is flush with the surrounding drywall. The screw head backs up the base to keep the joint looking good while the baseboard hides the drywall defect.

Tips for problem spotsKeeping baseboard straight will improve the look of a crooked wall or an out-of-square corner. When drywall is damaged or missing, keeping the board plumb can be tough.    |

Fine Homebuilding contributing editor Gary M. Katz lives in Reseda, Calif. His Web site is www.garymkatz.com. Photos by Roe A. Osborn.

From Fine Homebuilding #174