Tools for Shaping and Smoothing Trim

Learn about the basic tools you'll need to plane, rasp, chip, and sand trim boards.

Trim boards and wall panels sometimes need to be modified after cutting and before installation. Tools that plane, rasp, chip, and sand are all helpful from time to time.

Planes shave boards smooth and can also straighten out uneven conditions. A block plane is the most common type used for trim work. A small trimming plane can straighten uneven miter cuts. Surform tools remove material quickly, but leave a rough surface behind, which you can sand or plane smooth.

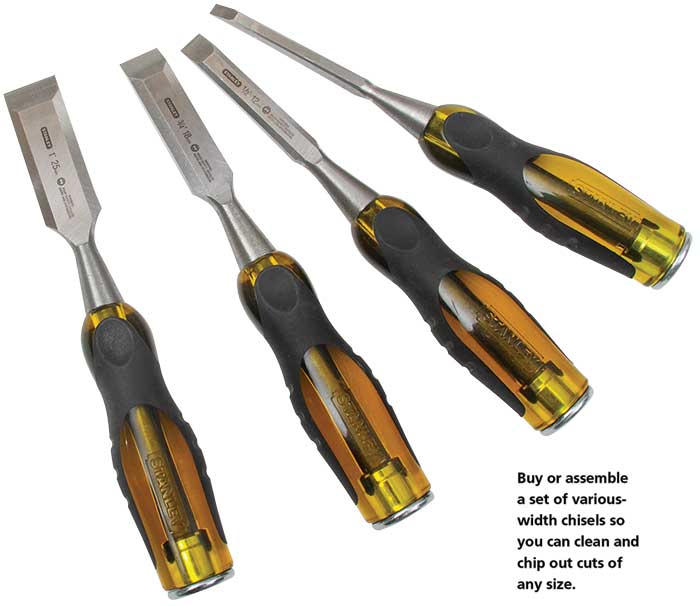

A very sharp chisel can be tapped with a hammer or pushed by hand to pare away material and clean up cuts. Chisels often finish or make cuts in places where no other tool can reach.

Trim boards and panels often have rough spots that need to be smoothed. Power sanders can make quick work of this. Use a belt sander—and use it carefully—only if you actually want to change the shape of a board, because it can eat away with surprising speed. A detail sander or random-orbit sander moves more gently, but still gets the job done. For final finishing, use hand sanders.

Router

A router can be used to ease a too-sharp edge, and can also create molding out of plain boards. Various router bits can create just about any profile you can imagine.

A router for trimwork does not have to be particularly powerful, and it doesn’t need fancy features. A fixed-base 1 1⁄4-horsepower router will work just fine. If you want to do elaborate scrollwork or work with bits that are wider than 1 in., then get a 2-horsepower router. Understand how to adjust the router for depth, and see that you can make microadjustments without difficulty.

| TIP: Make sure your router can handle the bits you want to use—either 1⁄4 in. or 1⁄2 in. Some routers can be adapted so that bits of either size will fit. |

|

|

Excerpted from Trim (The Taunton Press, 2015) by Steve Cory.