Wood and Other Trim Materials

Learn about the various options for trim boards, from unfinished softwood trim to synthetic moldings.

When shopping for moldings, you’ll see wood trim boards described by their species and MDF labeled as such. But synthetic moldings often are not listed by their actual material; you may need to read the literature closely to tell if it is polystyrene, vinyl, or PVC, for instance. Home centers and lumberyards carry different types, but here are some of the most common.

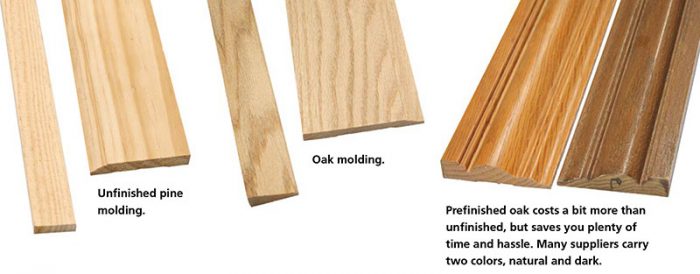

Unfinished softwood

Softwood trim is often made of pine but is sometimes fir or hemlock. Softwood is light and easy to cut and fasten, and has a natural handsome appeal. It is common to paint softwood, but careful staining and finishing can produce a rich appearance. Softwood is strong and fairly resistant to moderate exposure to moisture, but it can be dented.

Hardwood

Oak is the most popular and readily available type of hardwood molding, but if you’ve got some extra bucks you can go to a hardwood supplier and get maple, cherry, or even hickory. Hardwood trim is somewhat more difficult to cut and fasten than softwood, but if you prefer a natural or stained wood finish, it will give you a beautiful result, and it is difficult to dent as well.

Primed or painted

Painting can often take much longer than installing. So if you plan to paint the molding, consider buying primed or painted wood moldings. These moldings have the characteristics of softwood trim.

MDF trim

Medium-density fiberboard is heavier than natural wood, but it cuts and fastens fairly easily. Trim made of MDF comes with a solid coat of paint, and it’s often the least expensive option. MDF also resists denting. However, if it gets even a little wet, MDF will swell unattractively. So use it in rooms that are not likely to be moist, and apply primer to the back side before installing.

| TIP: If you want to stain your molding, resist the temptation to buy “paint grade” trim. It may look like you can stain it, but the results will be far less attractive than what you can achieve with “stain grade” molding. |

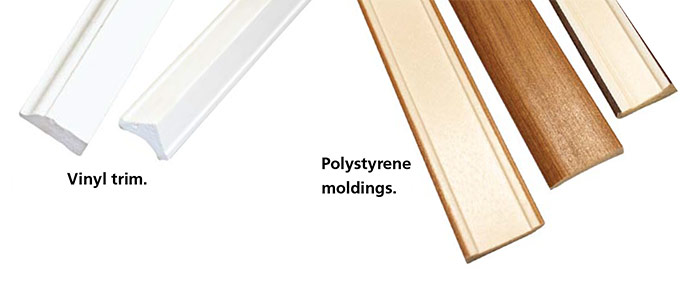

Polyurethane, vinyl, PVC

Moldings made with strong plastics like cellular vinyl, polyurethane, PVC, or even resin can be expensive, but they are easy to work with, strong, and completely immune to rot. Be sure the type you choose is paintable, and pay attention to the type of paint that is recommended. Often, a 100-percent acrylic paint is a good choice.

Polystyrene

Many home centers carry a line or two of inexpensive moldings that are very lightweight. Some have a printed faux-wood design, whereas others may be a solid color. Though the label may not say so, these are made of a plastic foam called polystyrene. These may be a good option in certain spaces, but be aware that they dent easily, and cutting or fastening imperfections cannot be hidden with caulk. Polystyrene should be installed with a nail gun; using a hammer with finish nails will lead to an unattractive installation. Painting this product can be difficult; you may need to apply an alcohol- or oil-based primer first.

Choosing boards

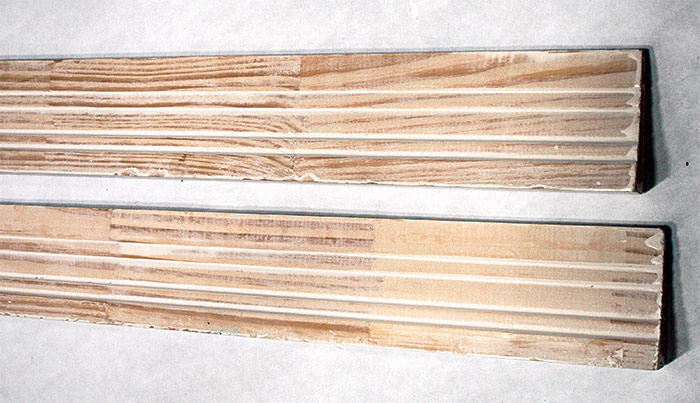

Synthetic trim boards are all pretty much the same, but wood boards can vary in quality. Because the boards are thin, minor curves and twists can be straightened out during installation, but pieces with severe distortion may crack during installation.

If a board is cupped—bowl-shaped along its width—try bending the board with your hands to straighten it. If you cannot, choose another board.

Sight down the length of a board. If it deflects more than 1⁄2 in. over the length of 8 ft., choose another board.

Some boards have indentations or a series of wavy marks left by the milling process. These will likely become more pronounced once the board is painted or stained. You could sand them out, but it is probably easiest just to choose another board.

Excerpted from Trim (The Taunton Press, 2015) by Steve Cory.