An Energy-Smart Foundation in Two Days

A compacted gravel footing is the only prep work required, and you don't have to wait for the weather.

Synopsis: Saving time on a building project often means saving money, too. North Carolina builder Tim Robinson saves both when he can by starting a project with insulated, precast concrete foundation walls. The panelized system Robinson uses is insulated with R-12.5 foam and has steel studs with holes punched for wiring and plumbing. Once a gravel footing has been compacted and leveled, the foundation walls can be dropped in place. This type of foundation system often can be set up in only two days: one day for prep work and one day for setting the walls.

We all know that time is money. That’s why waiting for the footings and foundation to go in can be one of the most frustrating aspects of any home-building project. Trying to get a house out of the ground in the winter is even more challenging.

One time-saving solution I’ve come to like involves the installation of insulated, precast concrete panels to construct a building’s foundation. I use a system from Superior Walls (www.superiorwalls.com), but the same benefits are available from other companies in different parts of the country. In most cases, after a site is excavated, I can install the whole system in two days: one day for prep and one day to set walls. Because these panels sit on a compacted gravel footing, my crew can do the prep work.

Is prefab more expensive than a poured or block foundation?The prefab foundation for this project cost $12,400. By comparison, the estimated cost for a block foundation framed with 2x4s was about $11,000. However, when you account for the cost of insulating a block foundation with 2-1 ⁄ 2 in. of foam, the price difference is a wash. But there’s more: I saved about a week of work, and job-site cleanup was nothing but a trash bag full of empty urethane sealant caulk tubes; no piles of broken block, empty soda cans, candy wrappers, or leftover cement block to deal with. A prefab foundation is best used where there is a full basement with consistent sill height. Different wall heights slow the process, minimizing the cost benefit. Although a prefab system might not be the best choice all of the time, it makes a lot of sense some of the time. |

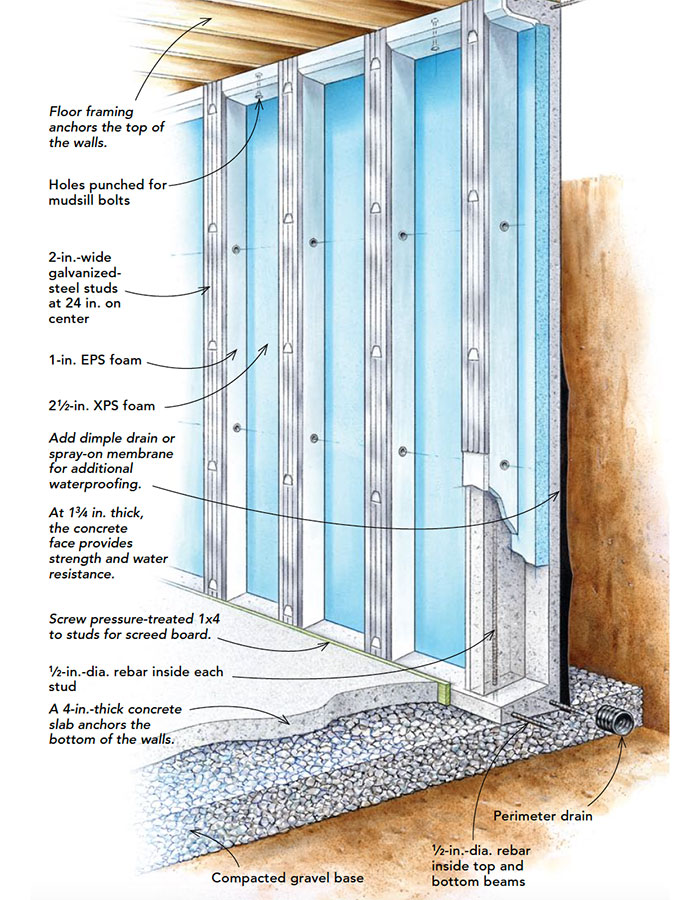

Not only are the panels quick to install, but they’re also insulated with 2½ in. of foam (R-12.5). The foam is visible on the inside surface of each panel; so are steel studs punched with holes for wiring and plumbing, making this type of foundation easy to finish inside. The outer concrete face is mixed at 5000 lb. per sq. in. (psi), versus the 2500-psi concrete in standard poured walls, so the prefab walls are practically bulletproof and waterproof. (For the record, the manufacturer says these panels are “damp-proof” and makes no claim about bullet resistance.) On this project, I elected to waterproof the foundation with a sprayed-on sealant and a dimple drain; that cost is minimal for the peace of mind gained.

The dense concrete shell has insulation and metal studs built in

Using a compacted gravel footing and preformed panels means the foundation goes up fast. But it’s also warm, water resistant, and ready for wallboard because the panels have foam insulation and steel studs with holes drilled for wiring and plumbing. The floor system secures the top of the foundation walls, and a concrete slab at the bottom resists the pressure of backfilling.

Drainage matters for all foundations

Because no concrete footing is used, the code governing wood foundations applies (International Residential Code section R402), specifically, ½-in. compacted gravel. The depth of the stone (4 in., in this case) depends on soil type and the combined load per lineal foot (dead load + live load + wind/snow load = combined load).

Drainage is important for all foundations; perimeter drains being the most common. Although code allows exceptions, Superior Walls does not. The perimeter drain’s gravel must extend below the frost line, so if you have a wall with no backfill against it, you need to dig a trench and fill it with gravel to set the wall on. This trench requires its own drain. The width and depth of the trench vary depending on your location.

The overall excavation should be at least 2 ft. larger than the foundation on all sides so that there’s ample room for the perimeter drain and room for the installers to work. If you decide to waterproof (required in some areas), you need this room. It’s also a safety issue (required by OSHA) to have at least 2 ft. of space from a foundation to the edge of the trench. On a simple rectangular foundation, we locate the two back corners first to ensure that we have this 2 ft. of working space behind the wall. Next, we pull the correct measurement perpendicular to this line and make a 3-ft. to 4-ft. arc in the gravel. After calculating the diagonal measurement of the building, I measure from the back pins to where that measurement intersects the arc to find the other two corners.

One day, two machines, 300 bucks

With the rental of a skid steer ($250 per day) and a compactor ($50 per day), we can place and pack the gravel in less than a day. To keep the gravel bed even, I set up a builder’s level in an out-of-the-way corner and measure off the level to set grade pegs throughout the footprint roughly 8 ft. to 10 ft. apart. Working from back to front, we fill in the gravel, raking it to the height of the grade stakes. Two carpenters easily can keep ahead of one skid steer, and working back to front like this, I never have to drive the skid steer on a finished area.

After the gravel is leveled, we tamp the entire area, reshoot grade, and fill in the low spots. The tolerances aren’t exactly rocket science; the installation crew requires only that the gravel be within an inch of level. They’ll compact it and level it again before setting the walls.

Factory crew sets the walls

The walls are trucked to the site in sections that fit together nicely. Stainless-steel bolts hold the panels together, and urethane sealant keeps the joints watertight. Because the walls are precast and square, the gravel base must be perfectly flat and level. That’s why the installers reshoot grade, repack the gravel, and relevel it all. The project featured here is a cabin on top of a mountain accessed by narrow roads, so the walls had to be transferred from a semi-truck to a couple of smaller dump trucks that could navigate the hill.

Starting in a corner, a crane lifts the walls into place. The installers plumb and brace the wall; then the rest of the panels slide into place quickly, with no additional bracing required. I hope that my block mason isn’t reading this because I’ve never had a masonry wall turn out as well or as fast. At the end of the day, the diagonal measurement was within 1 ⁄ 4 in. of square.

A concrete slab anchors the bottom; floor framing locks the top

Because this foundation is composed of sections, it’s possible that the joint between each panel could fold like a hinge under the pressure of backfilling, so the tops and bottoms of the walls need to be reinforced. A slab locks the bottom of the wall, and the floor framing secures the top.

Blocking details in the floor framing resist inward force on walls parallel to the floor joists; they’re explained and illustrated in the Builder’s Guideline Booklet from Superior Walls. Longer walls might require shear walls to provide extra bracing, depending on how tall the walls are and how much backfill will be placed against them.

Superior Walls panels come in three standard heights: 8 ft. 2 in., 9 ft., and 10 ft. You also can order custom heights; however, the cost advantage begins to diminish for crawlspace and irregular-foundation details. For this project, the manufacturer needed three to four weeks of lead time after the plans were finalized, but that can vary depending on complexity, location, and time of year. The blueprints must be accurate, showing all point loads, window and door positions, and partition walls. While you can change the backing for interior partition walls pretty easily in the field, point loads must be engineered into the wall panels.

Precast foundation systems probably won’t become my standard operating procedure anytime soon, but I use them whenever I can. The speed, quality, and price are hard to beat. Two days after the hole is dug, I’m framing a floor. To me, that’s priceless.

—Tim Robinson and his wife, Anna, own Homeworks Construction in Brevard, N.C.

Photos by Daniel S. Morrison, except where noted.

For more photos, drawings, and details, click the View PDF button below:

From Fine Homebuilding #186

Sources of prefab foundation systems:

CarbonCast

Available in North America

866-462-5887

Superior Walls

Available in Eastern part of United States and in some Western states

800-452-9255

Thermal-Krete

Available in New York and Pennsylvania

716-434-6157

View Comments

What seismic zones do these work in?