Basement Insulation Retrofits

When finishing a basement, it pays to consider moisture management, air sealing, and insulation.

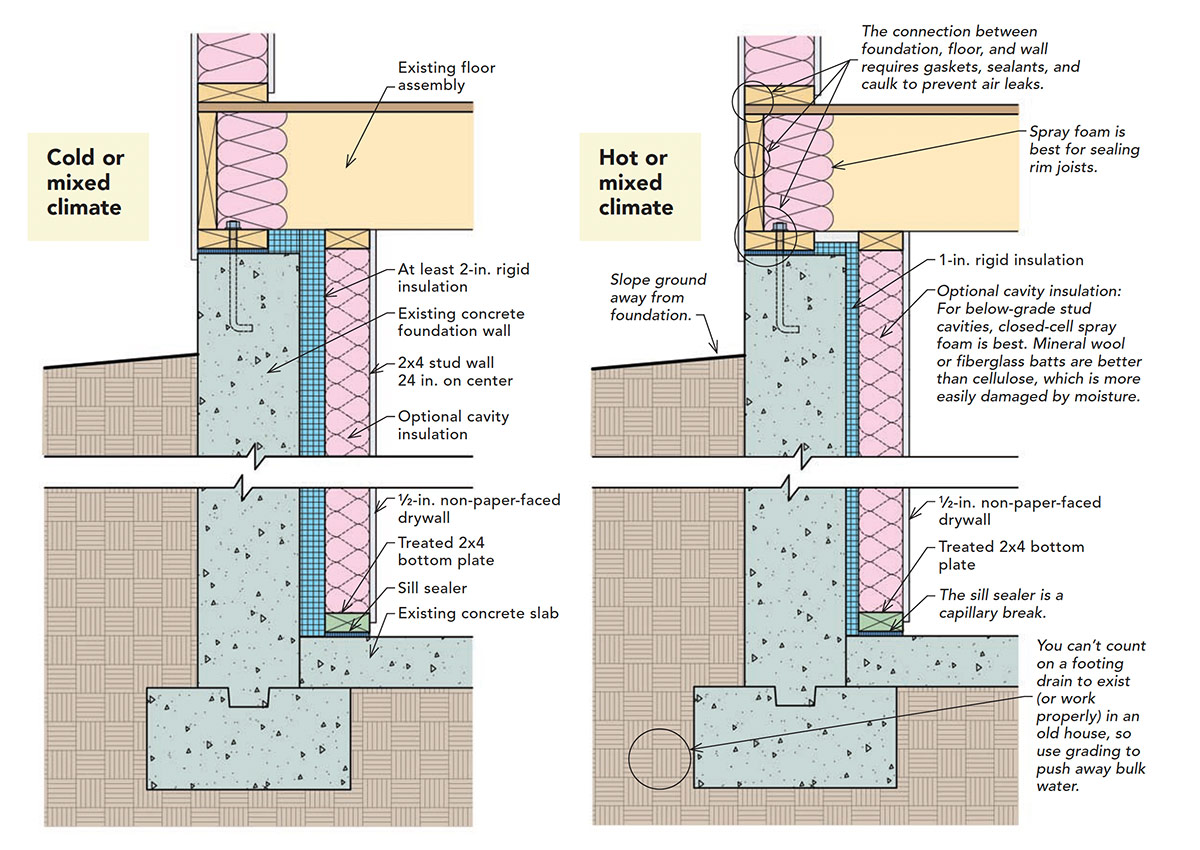

Finished basements are a great way to add living space to a house without adding on. You often can add almost as much living space as the main floor offers. Before thinking about flooring choices and paint colors, though, think about the basics. Moisture, insulation, and air infiltration must be tackled before any finish materials are installed. In new construction, these issues are addressed from the outside before the basement is backfilled. Retrofits mean that you have to work from the inside. In either case, it is important to consider the climate before work begins.

Start with water management

Because basements are mostly buried in the ground, they are sometimes wet, are usually damp, and are seldom dry. Rarely do old houses have perimeter-drainage systems, insulation, or capillary breaks. When converting a basement to living space, the basement must manage moisture better than it did before the insulating and air-sealing because a tighter basement is less able to dry out when it becomes wet.

You can use grading to manage bulk groundwater on the outside, but foundations also have to disrupt capillarity—which is the force that causes water to naturally rise through the small cavities in porous materials. Water in the soil can and will wick all the way up to the roof framing if you let it. Capillary breaks such as brush-on damp-proofing, sill sealer, and rigid insulation can block this process.

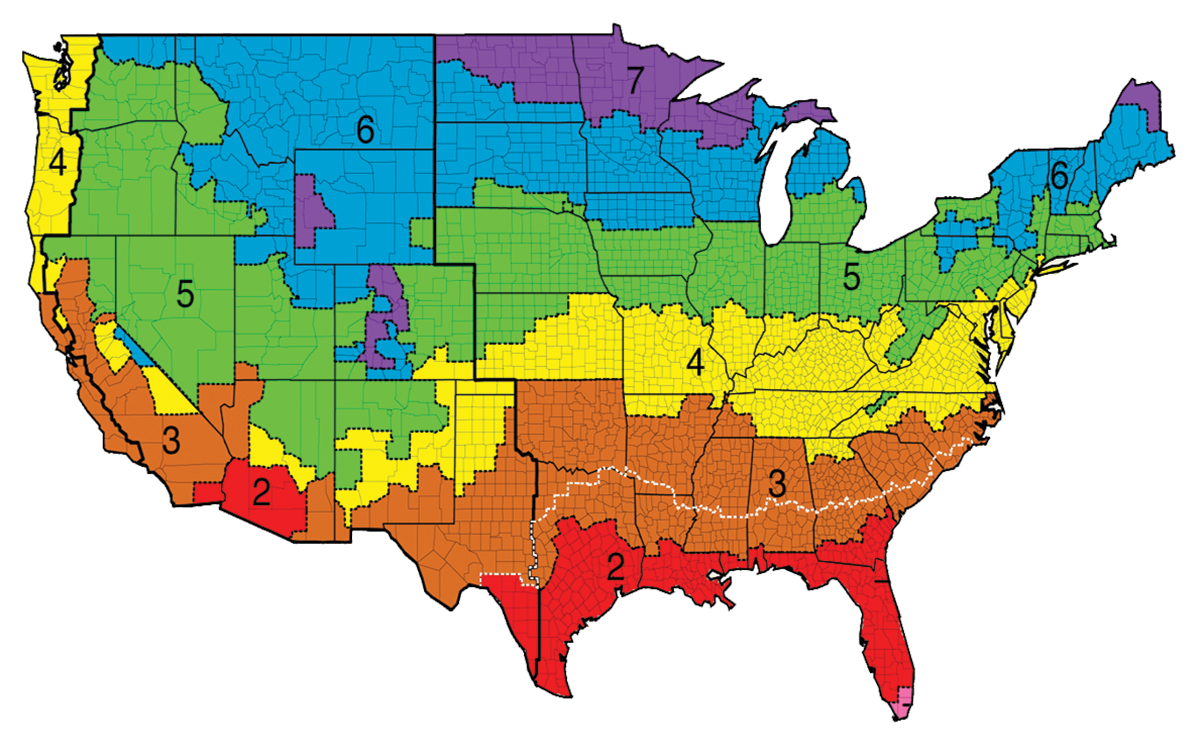

R-Value minimums by code and climate zone

|

Air-Sealing saves energy and stops moisture

The connection between concrete foundations and wood framing is almost always leaky because wood is often warped and concrete is rarely flat. Air leaks waste energy and cause moisture problems. Most basement air leaks occur between the top of the concrete wall and the bottom of the subfloor, where there are many joints and connections. The easiest way to seal and insulate the rim-joist area is with spray foam, but blocks of rigid foam sealed in place can work well, too.

Insulation: More is better

Rigid-foam insulation in a basement eliminates condensation by keeping the interior surface of the foundation warm. How much insulation you need depends on your climate zone, though energy-conscious builders strive to exceed code minimums. While it’s possible to meet code minimums with rigid foam alone, you also can use a combination of rigid foam and cavity insulation.

Which rigid insulation should I use?

Insulation amount depends on location

The International Residential Code (IRC) specifies particular R-values for each climate zone; how you get there is up to you. For very cold climates, you may need to add extrathick rigid insulation or fill the stud cavities. Don’t, however, treat a below-grade wall like a regular wall. Expect bulk-water problems, and choose insulation that can handle it. Never include a plastic vapor barrier when insulating a basement wall, because it will trap moisture.

Daniel S. Morrison is managing editor of GreenBuildingAdvisor.com.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Utility Knife

Insulation Knife

Nitrile Work Gloves

View Comments

Basement insulation is very important.

I really want to find out why foil faced rigid insulation is the most preferred insulation type but using plastic vapor barrier isn't allowed? Foil is completely vapor impermeable. The "no plastic vapor barrier" seems like a rule that people follow blindly. If there is no organic material and you have a drain for any bulk water, what is the harm of stopping that vapor completely with a vapor barrier instead of blocking it completely with foil faced or slowing the vapor movement down severely with multiple layers of rigid foam. I would think you might as well stop it right at the wall instead of allowing it to move through your wall system.