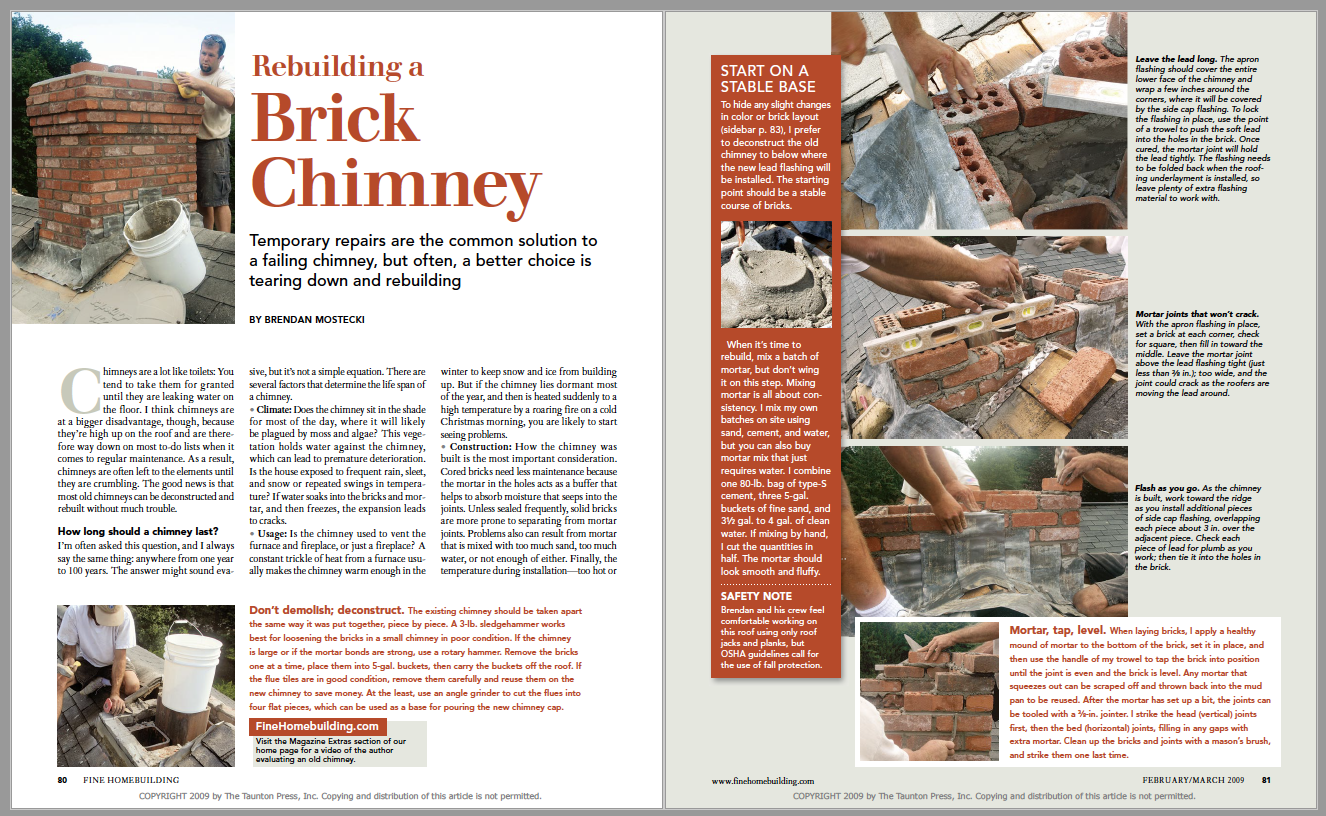

Rebuilding a Brick Chimney

Temporary repairs are the common solution to a failing chimney, but often a better choice is tearing down and rebuilding.

Synopsis: Although most homeowners probably don’t think much about their chimneys, they should. When problems become apparent, it’s often too late for simple repairs. Mason Brendon Mostecki says that when chimney problems arise, the best bet is often tearing down and rebuilding. Mostecki says that chimney life depends on a few factors: climate, usage, construction. To replace a chimney for a long life, Mostecki starts rebuilding the bricks on a stable base, then works to get the height right. He also promotes regular maintenance to enhance a chimney’s life span. This article includes a sidebar about choosing proper brick size when rebuilding or repairing a chimney.

Magazine extra: Watch Brendan Mostecki inspect a failing chimney and detail his recommendations for its reconstruction.

Chimneys are a lot like toilets: You tend to take them for granted until they are leaking water on the floor. I think chimneys are at a bigger disadvantage, though, because they’re high up on the roof and are therefore way down on most to-do lists when it comes to regular maintenance. As a result, chimneys are often left to the elements until they are crumbling. The good news is that most old chimneys can be deconstructed and rebuilt without much trouble.

How long should a chimney last?

I’m often asked this question, and I always say the same thing: anywhere from one year to 100 years. The answer might sound evasive, but it’s not a simple equation. There are several factors that determine the life span of a chimney.

- Climate: Does the chimney sit in the shade for most of the day, where it will likely be plagued by moss and algae? This vegetation holds water against the chimney, which can lead to premature deterioration. Is the house exposed to frequent rain, sleet, and snow or repeated swings in temperature? If water soaks into the bricks and mortar, and then freezes, the expansion leads to cracks.

- Usage: Is the chimney used to vent the furnace and fireplace, or just a fireplace? A constant trickle of heat from a furnace usually makes the chimney warm enough in the winter to keep snow and ice from building up. But if the chimney lies dormant most of the year, and then is heated suddenly to a high temperature by a roaring fire on a cold Christmas morning, you are likely to start seeing problems.

- Construction: How the chimney was built is the most important consideration. Cored bricks need less maintenance because the mortar in the holes acts as a buffer that helps to absorb moisture that seeps into the joints. Unless sealed frequently, solid bricks are more prone to separating from mortar joints. Problems also can result from mortar that is mixed with too much sand, too much water, or not enough of either. Finally, the temperature during installation — too hot or too cold — can affect the way the mortar sets up and the concrete crown cures.

Maintenance matters

Assuming a competent mason, the right materials, and an average environment, a minimally maintained chimney will likely last from 15 to 30 years before it needs a major maintenance overhaul, a crown replacement, or a rebuild. As with most things, regular maintenance will help to extend this life span. I recommend that the chimney be sealed twice a year for the first two years, then every other year after that. I’ve had great luck with Umaco’s transparent penetrating sealers (www.umaco.com). For a matte look, choose a breathable sealer. If the high-gloss look doesn’t bother you and you really want to seal the chimney thoroughly, use a nonbreathable sealer.

If cracks appear, I seal them using a silicone caulk with a masonry bonding strength of 10. Before applying caulk, I clean the crack with a brush; then I apply the silicone to both the crack and to the area surrounding the crack.

Not every older chimney needs to be torn down and rebuilt. Often, the deterioration is limited to the chimney’s concrete crown, which takes the most abuse from sunlight, snow, and ice. In this case, the crown can be chiseled away and repoured. If the clay flue tile is in poor condition, it’s most easily repaired at the same time, before the new crown is poured. If the mortar joints between bricks are loose or crumbling, they can be cut back with an angle grinder, washed with acid, and repointed with fresh mortar.

Brendan Mostecki is a mason in Leominster, Mass.

Brendan Mostecki is a mason in Leominster, Mass.

Photos by Justin Fink.

From Fine Homebuilding #201

Click the View PDF button below to read the entire article: