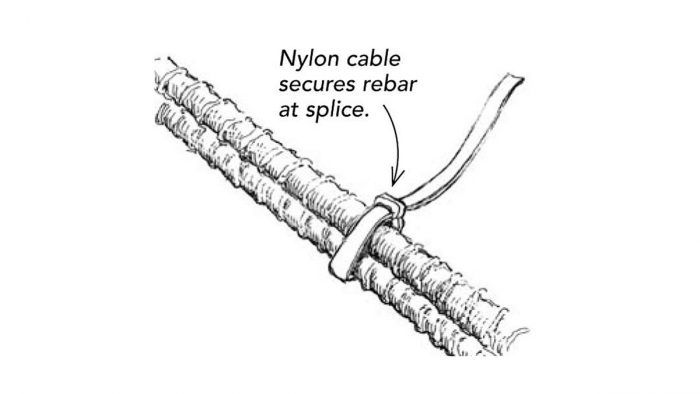

Splicing Rebar

Nylon cable ties are a convenient alternative to traditional rebar wire ties, especially when working in tight spaces.

I do a lot of concrete work using insulating concrete forms (ICFs), which are hollow foam blocks that are stacked atop one another, then filled with concrete. A network of horizontal and vertical rebar ties the whole thing together. Working inside the foam blocks can be pretty close quarters, so using the typical winder-with-wire rebar splicing method isn’t convenient. As an alternative, I’ve found that nylon cable ties are a much quicker way to make splices. They are plenty strong and are readily available at any hardware store.

— Paul Rawlings; London, Ont., Canada

From Fine Homebuilding #178

RELATED STORIES

- Placing Concrete in the ICF Foundation

- Stronger, Lighter Rebar

- An Introduction to Insulated Concrete Forms

Got a Tip?

Do you have any great tips like this one on how to splice rebar with nylon cable ties? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

I cannot believe that this is in compliance building codes Could an engineer or someone truly familiar with please comment on this.

It's my understanding that the traditional wire ties are just there to keep the rebar flying in close formation and the intended location. It's the overlap that creates the strength- it needs to be long enough to develop the full strength of the connection between the rebar and the concrete. Higher grade rebar requires longer overlap to develop the strength, higher grade concrete allows less overlap. Tight overlaps require more length because the concrete can't wrap all around the rebar to develop the strength. Separated overlaps can be shorter.

Your engineer or architect should specify the required overlap for each situation.

If you think about the relative strength of the wire to the rebar, it makes sense the wire isn't really there for strength- as soon as the concrete sets, the wire has done its job, and so nylon tie-straps work too.