Avoiding Common Framing Errors

By paying attention to some basic details, you can avoid the framing mistakes that building inspectors encounter most frequently.

Synopsis: From mudsills that aren’t bolted down to collar ties put in the wrong place, mistakes in rough framing can get you on the wrong side of your local building inspector and lead to structural problems down the road. This article offers tips on avoiding them.

When it comes to building inspectors, I’m like the teenager who thought his father was a poor simpleton who knew nothing about anything. A few years later, after the son had a child of his own, he was amazed at how much the old man had learned in such a short time. The truth is, I’m amazed by how much building inspectors have learned since I began working in construction 12 years ago.

As a builder/remodeler, I sometimes thought that building inspectors pushed points in the code that didn’t seem all that important. But after years of learning — from my own mistakes and the mistakes of others — I now understand that the code really provides only minimum requirements for health and safety. It’s important to remember that if there is a code violation, the builder assumes all responsibility, and the building official assumes none.

Remember, too, that the importance of some code issues isn’t obvious until the integrity of a structure is tested by some sort of a natural disaster. Hurricanes are perfect examples. Most people in a storm’s path aren’t aware of any code violations until their buildings collapse during the storm. Improperly secured plywood blows off roofs. Some buildings blow off their foundations because of inadequate anchoring.

The house must be anchored firmly to its foundation

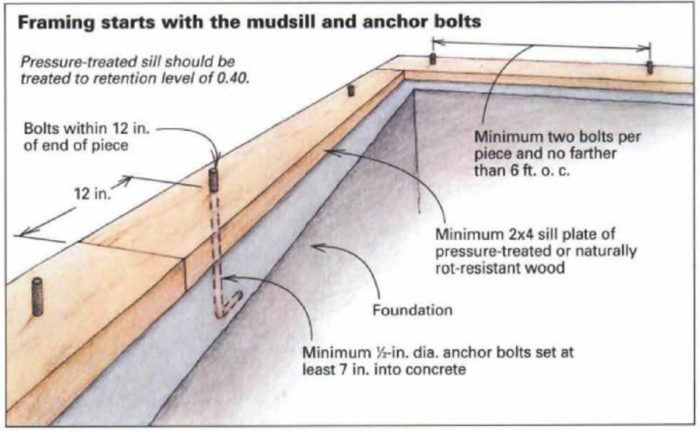

According to the code, sill plates must provide a minimum protection against termite and decay damage and must be of pressure-treated lumber or naturally rot-resistant wood such as heartwood or redwood, black locust or cedar.

Before I knew better, I used pressure-treated lumber that was treated to 0.25, which refers to the retention level of the wood preservatives that are forced into the wood. However, I should have used lumber that had a retention level of 0.40. According to the Southern Forest Products Association, 0.40-retention, or ground-contact, lumber is required anytime treated lumber comes in contact with concrete that contacts the ground. To know if lumber has been treated to level 0.40, read the grade stamp on the lumber or the tag stapled to the lumber.

Once the sills are in place, they must be anchored to the foundation. According to the Council of American Building Officials’ (CABO) model code, anchor bolts may not be placed less than 7 in. into concrete, must be a minimum of 1/2 in. in dia. and must be spaced no farther than 6 ft. o. c. Also, each section of sill must have at least two bolts that go through a minimum 2×4 stock, and the bolts must be placed within 12 in. of the ends of the sills.

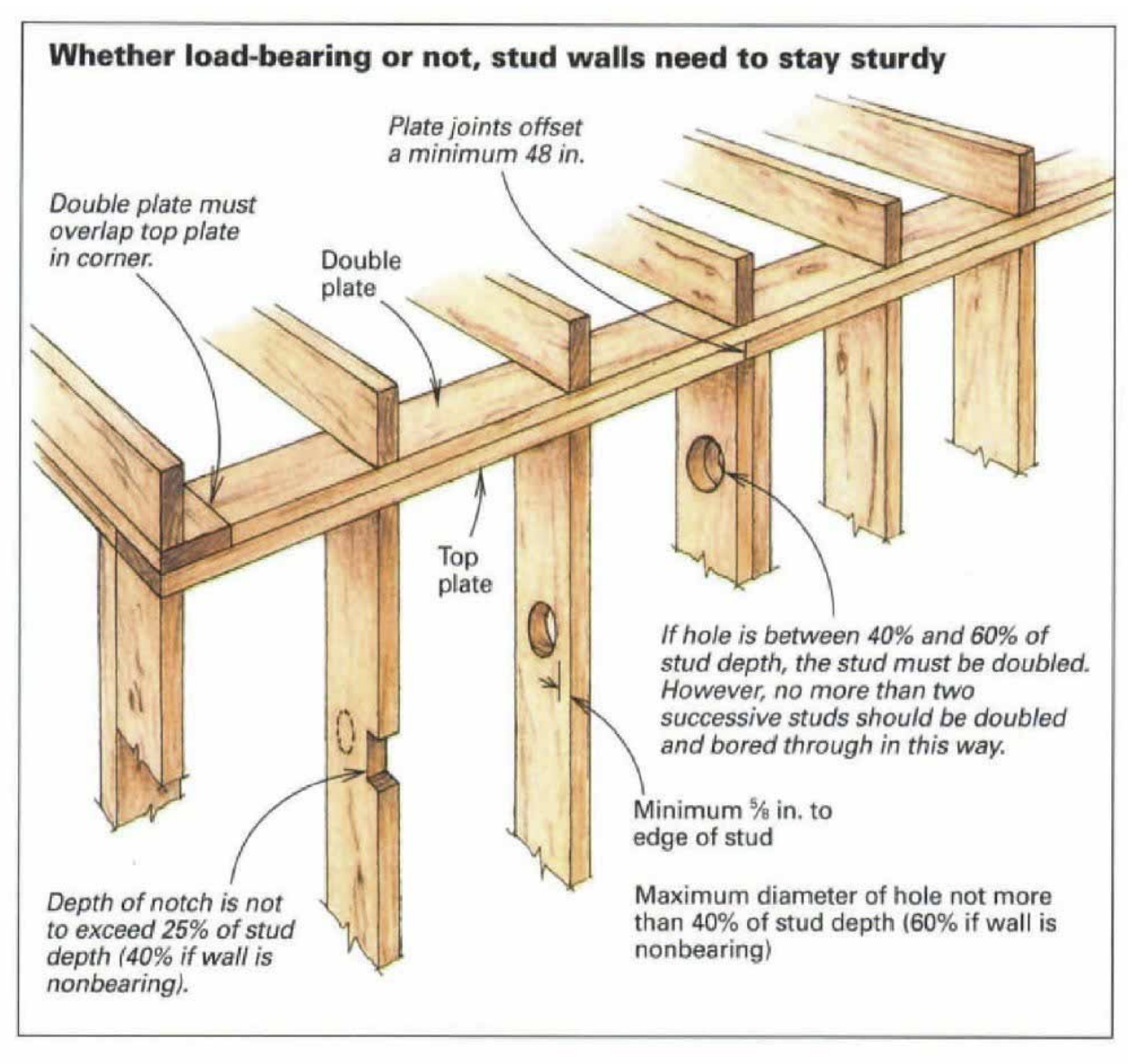

Top plates require offset joints and adequate fastening

I remember photographs of damage inflicted by hurricane Hugo. One photo showed a wall that had let go because a joint in the double top plate was inadequately offset from another. The whole wall gave way between those two joints.

Improper fastening and offsetting of double top-plate joints are the most common errors found in bearing-wall construction. By code, the double plate must overlap the top plate in the corners. Joints in the top plate must be offset by a minimum of 48 in. from joints in the double plate (drawings facing page). Overlapping provides a continuous tie in the walls. Most of my residential-framing experience has been limited to framing 16 in. o. c. and to double top plating. When you’re framing this way, there are no limitations on how close rafters, floor joists or bottom chords of roof trusses must be to the supporting studs underneath. If you frame using a double 2×6 top plate, you can space your studs up to 24 in. o. c. and place a supporting member at any point above it. If it’s a 2×4 frame that’s 24 in. o. c. and has a double top plate, whatever is supported above it must be within 5 in. of the stud below it.

From Fine Homebuilding #106

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

100-ft. Tape Measure

Flashing Boot

Original Speed Square