A Better Wall for Production Builders

Designing a better wall system isn’t particularly hard. Designing one with a chance of being accepted by production builders, on the other hand, has proven difficult...and that’s a problem.

Demand for higher-performance wall systems is growing, partly because of more-stringent energy codes. But builders aren’t adopting existing solutions—things like double-wall framing or thick layers of exterior rigid foam over wall sheathing—in significant numbers.

The National Association of Home Builders’ (NAHB) Home Innovation Research Labs is trying to lure more builders into constructing high-efficiency walls with the development of its “Extended Plate and Beam” wall system.

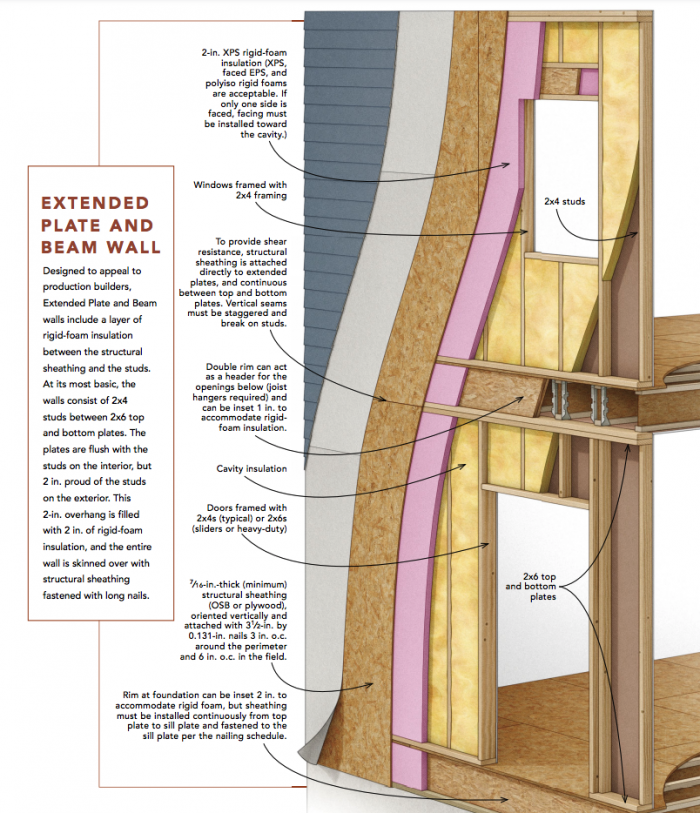

Called EP&B for short, Extended Plate and Beam adapts methods that production builders—who build the majority of American homes—already know. At its most basic, EP&B consists of 2×4 studs between 2×6 top and bottom plates, and the extra 2-in. overhang is filled with rigid foam before structural sheathing is attached with long nails (see drawing right). From there, installing windows, doors, flashing, and cladding is largely the same as for a regular 2×6 wall.

The main advantage to production builders? Installing OSB or plywood outboard of the rigid foam removes the need for furring strips.

EP&B vs. other walls

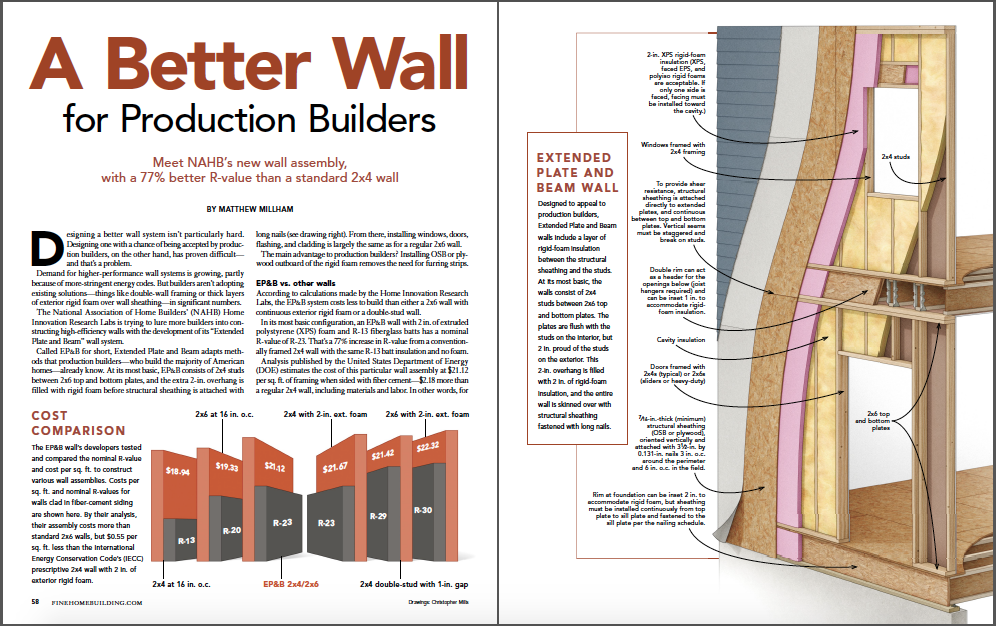

According to calculations made by the Home Innovation Research Labs, the EP&B system costs less to build than either a 2×6 wall with continuous exterior rigid foam or a double-stud wall.

In its most basic configuration, an EP&B wall with 2 in. of extruded polystyrene (XPS) foam and R-13 fiberglass batts has a nominal R-value of R-23. That’s a 77% increase in R-value from a conventionally framed 2×4 wall with the same R-13 batt insulation and no foam.

Analysis published by the United States Department of Energy (DOE) estimates the cost of this particular wall assembly at $21.12 per sq. ft. of framing when sided with fiber cement—$2.18 more than a regular 2×4 wall, including materials and labor. In other words, for an 11.5% premium, they saw a 77% bump in nominal R-value.

Builders can also build an EP&B wall with 2×6 studs and 2×8 plates. But because a 2×8 is only 7-1⁄4 in. wide, the remaining overhang leaves room for only 1-3⁄4 in. of rigid foam, producing a nominal R-29 wall with XPS and fiberglass batts. (Builders can rip 2x10s down to 7-1⁄2 in. to get a full 2 in. of foam and an R-30 wall.) By comparison, a standard 2×6 wall with fiberglass batts has a nominal R-value of R-20, according to DOE analysis.

While the system reduces thermal bridging at the studs, the rigid foam doesn’t cover the plates (or, in its most basic configuration, the rim joists), resulting in more thermal bridging—and in most cases more air leakage—than systems with continuous insulation.

The devil is in the framing and fastening details

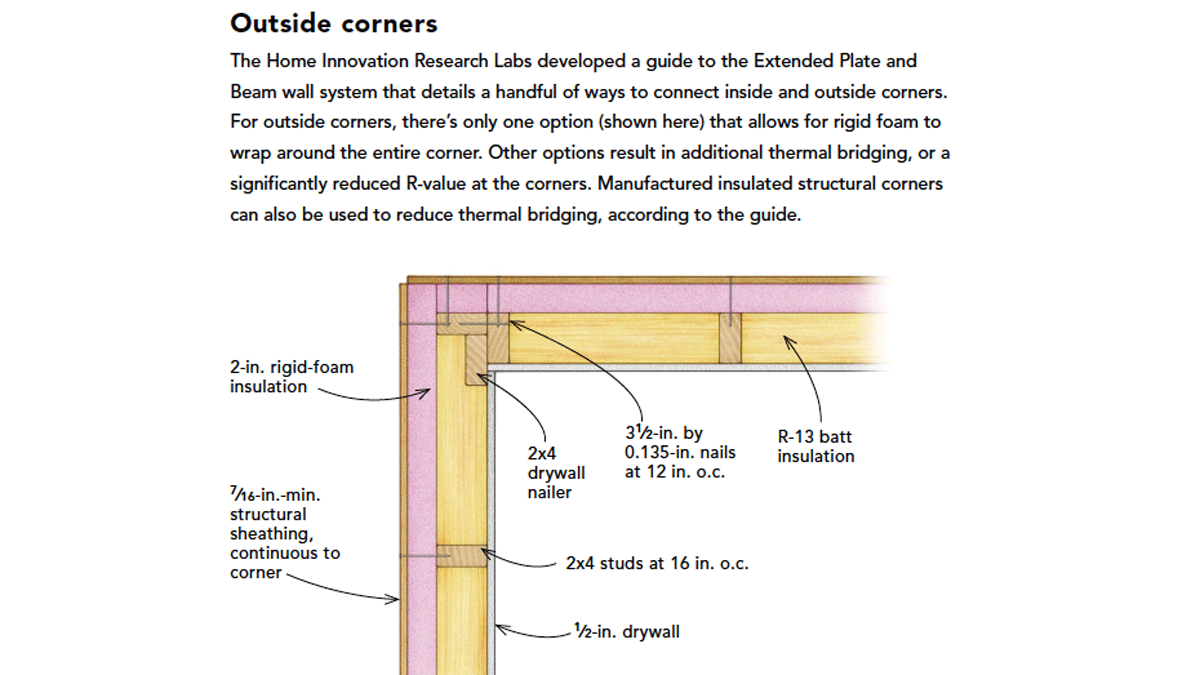

The Home Innovation Research Labs produced a manual, titled “A Builder’s Guide: Extended Plate & Beam Wall System,” which gives options for various framing details.

The manual notes that EP&B walls need 3-1/2-in. nails every 3 in. on the edges of sheathing panels and every 6 in. along studs for adequate bracing. While this approach works in most of the country, it is not suitable for high-seismic or high-wind areas.

The “Beam” in Extended Plate and Beam refers to the rim joists, which can be doubled up so that structural headers over openings aren’t necessary. Thermal bridging can be further reduced—by more than 95% overall, according to developers—if the rim is inset to accommodate rigid-foam insulation. Doing this can, however, add complexity.

Siding weighing less than 3 lb. per sq. in. can be fastened to the sheathing with standard nails, though heavier siding requires fasteners that extend to the studs.

Awaiting code approval

This system is not yet recognized by the International Residential Code, though its developers are hoping to get approval at upcoming code hearings.

Until codes change, local code officials may give this approach a thumbs-down unless a builder submits engineering documents validating the system’s soundness.

For more information, including technical diagrams, click the View PDF button below.

For more information, including technical diagrams, click the View PDF button below.

From Fine Homebuilding #273