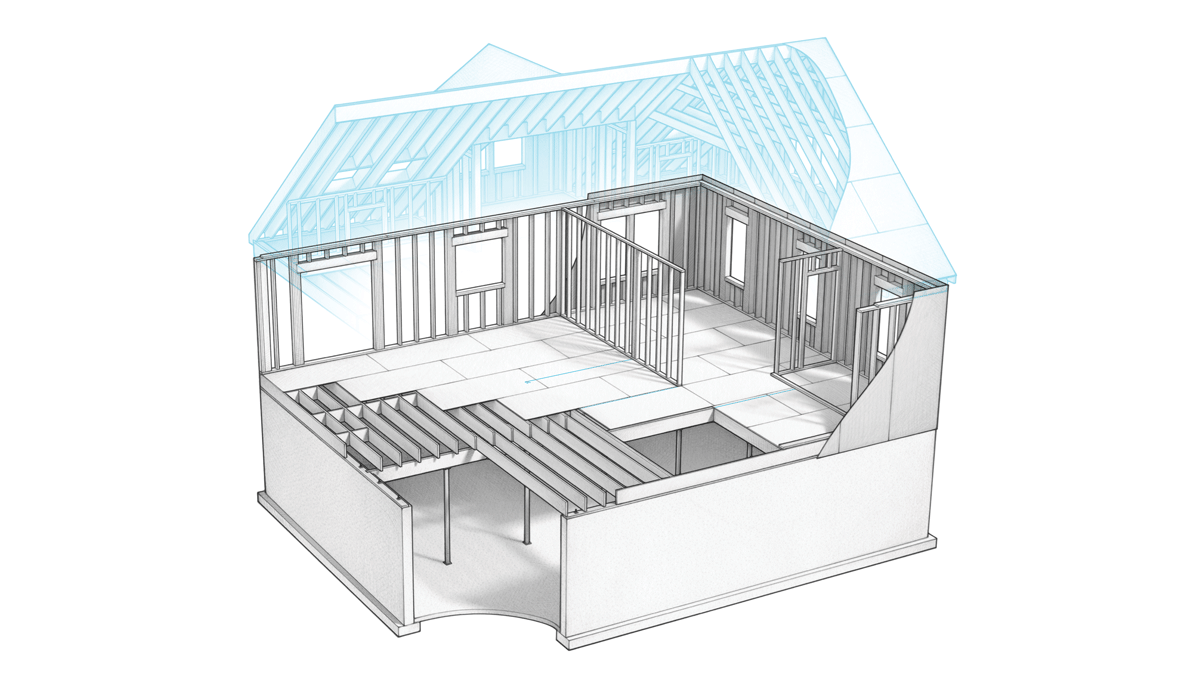

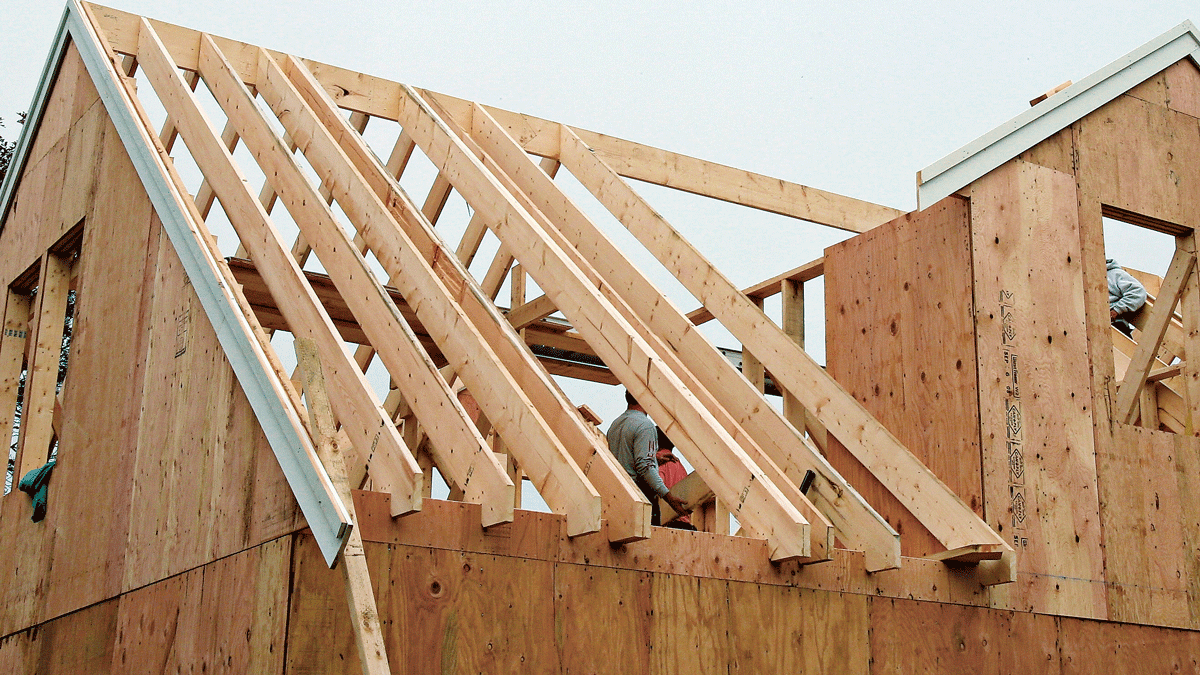

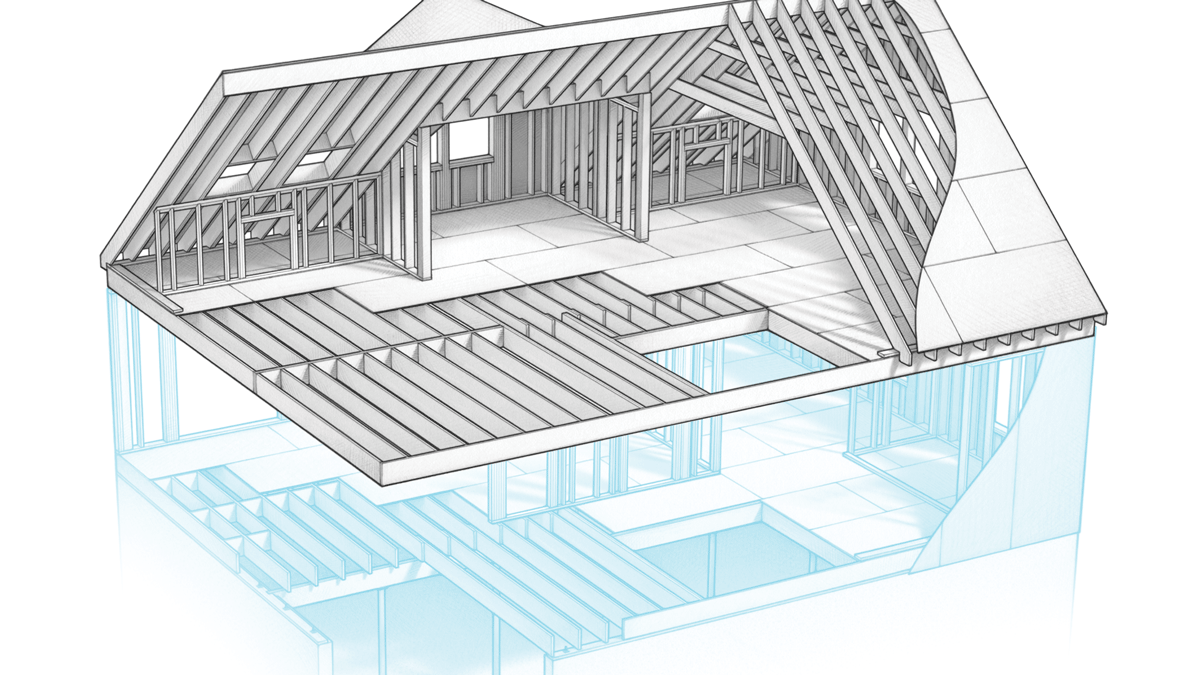

Components of a House Frame

Here's a glossary of all the parts of the frame from mudsills to collar ties.

Before you frame a house, you need to know the parts of the frame and how they work. The following discussion roughly reflects the order in which the parts are built in the framing process.

Parts of the Frame

Rafters, Second-floor support beam, Roof sheathing, Ceiling joist, Collar tie, Ridge

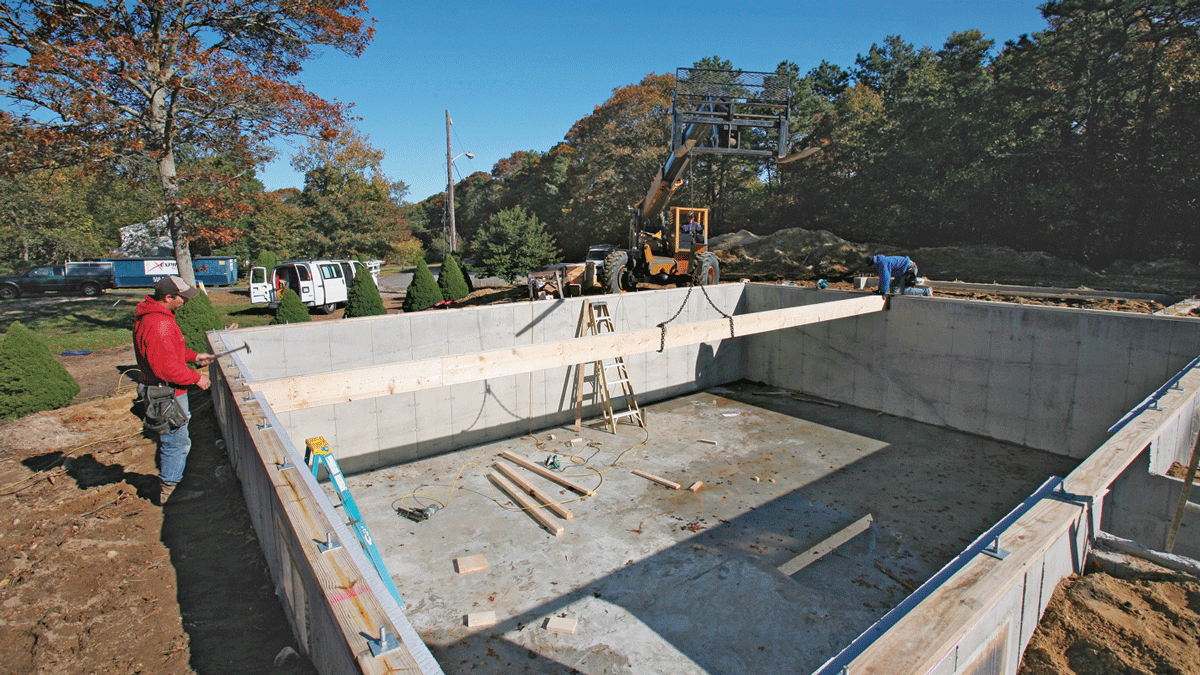

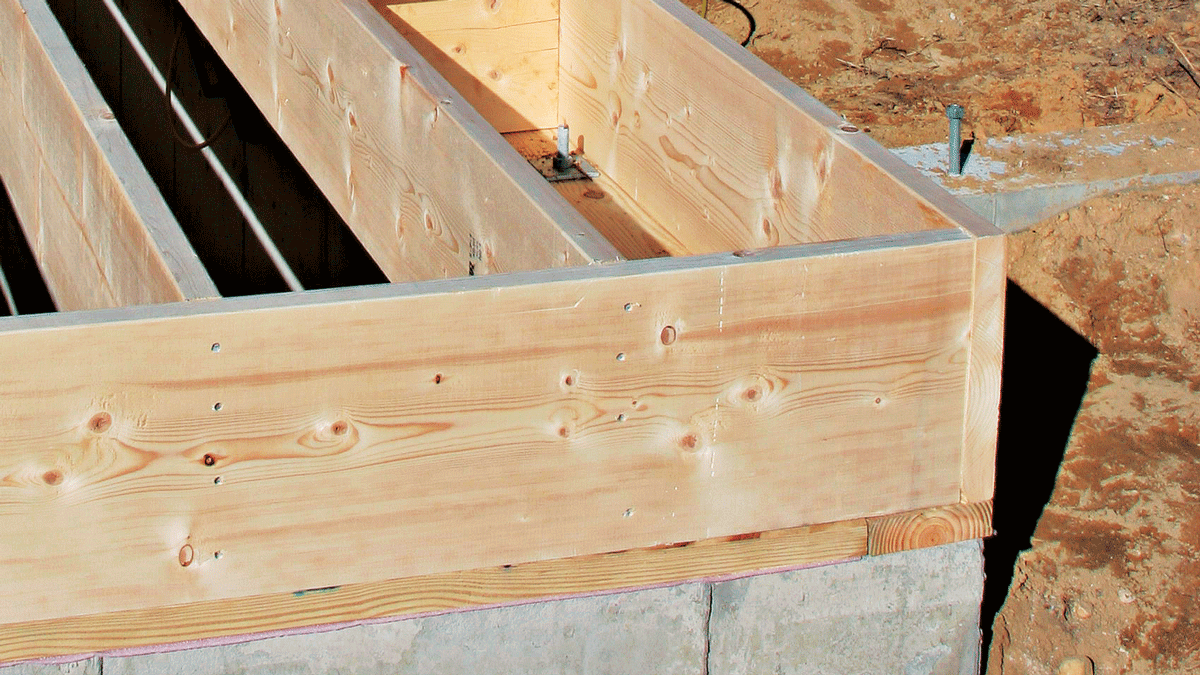

Mudsills

Pressure-treated lengths of 2×6 lumber, which form the first layer of the mudsill, are solidly attached to the foundation with bolts that have been embedded in the foundation walls. They provide a bearing surface that prevents contact between the untreated floor joists and the concrete foundation. A second layer of standard lumber is sometimes applied over the pressure-treated boards. That layer can be used to help level the mudsill, and the light-colored wood makes the layout marks easy to read. However, most mudsills are built with a single layer of pressure-treated lumber.

Support beam

Also called a center beam, the support beam bears the first-floor joists if they are not long enough to span the entire distance between foundation walls. The ends of the support beam bear on the foundation walls; intermediate support below the beam is usually provided by Lally columns (hollow-metal columns filled with concrete). The top of the beam should be on the same plane as the top surface of the mudsills.

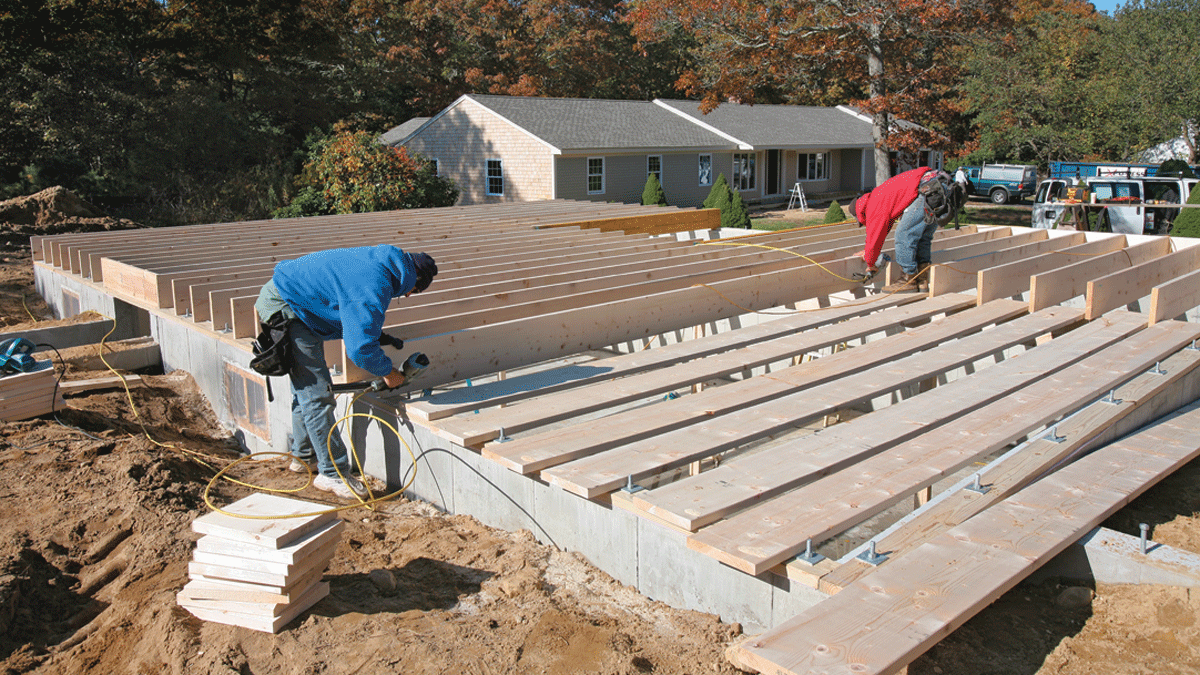

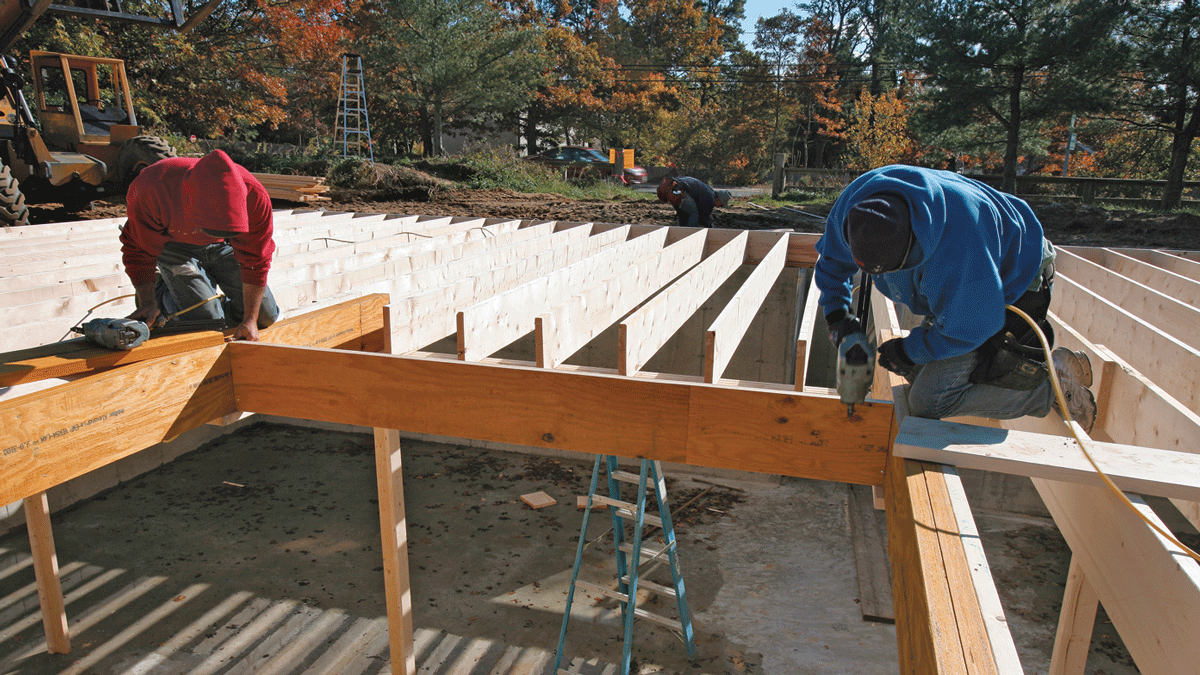

Floor joists

Floor joists are horizontal lengths of lumber placed on edge to span the area between the mudsills and the support beam. The joists must be nailed to the support beam, the rim joists, and the mudsills.

Rim joists

Rim joists are the same material and dimension as the floor joists but rest entirely on the outer edge of the mudsills. They must be nailed both to the mudsills and to the ends of the floor joists. They close off the ends of the joist bays and help hold the joists in a vertical position.

Floor header

Some of the floor joists must be cut short to create openings for features such as stairs and chimneys. A floor header supports the ends of the interrupted joists. Headers are often made of two or more lengths of floor-joist stock sandwiched together but can also be made of manufactured material such as laminated veneer lumber (LVL), as in this house. To carry the extra load placed on them by the headers, the floor joists on either side of the opening must be doubled or tripled.

Blocking

Building codes often require that short pieces of lumber, called blocking, be nailed between joists and rafters to reinforce or stiffen the floor or roof system. When blocks are installed in a row at the midspan of the joists and run the entire length of the building, they are called bridging. Blocking can also be installed between wall studs to make it easier to support such things as handrails, towel bars, and cabinets.

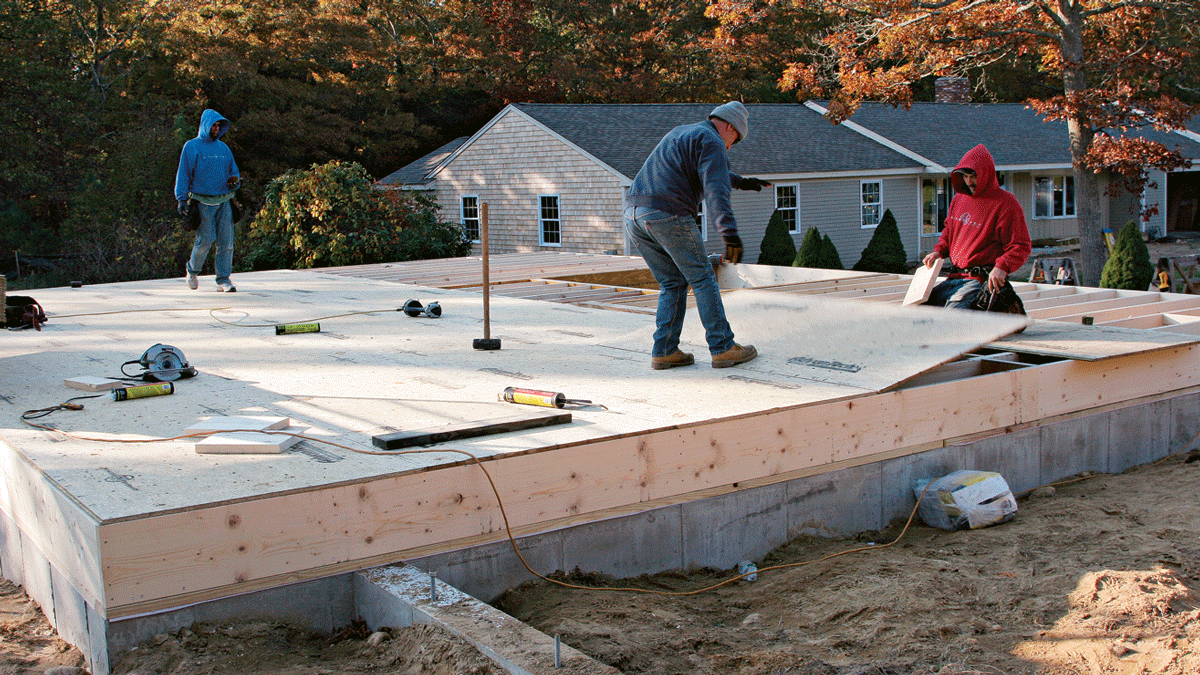

Floor sheathing

Floor sheathing is a layer of plywood or oriented-strand board (OSB) that is nailed and glued to the top edge of the floor joists. Floor sheathing stabilizes the joists and provides a solid, flat base for wall framing and finish flooring.

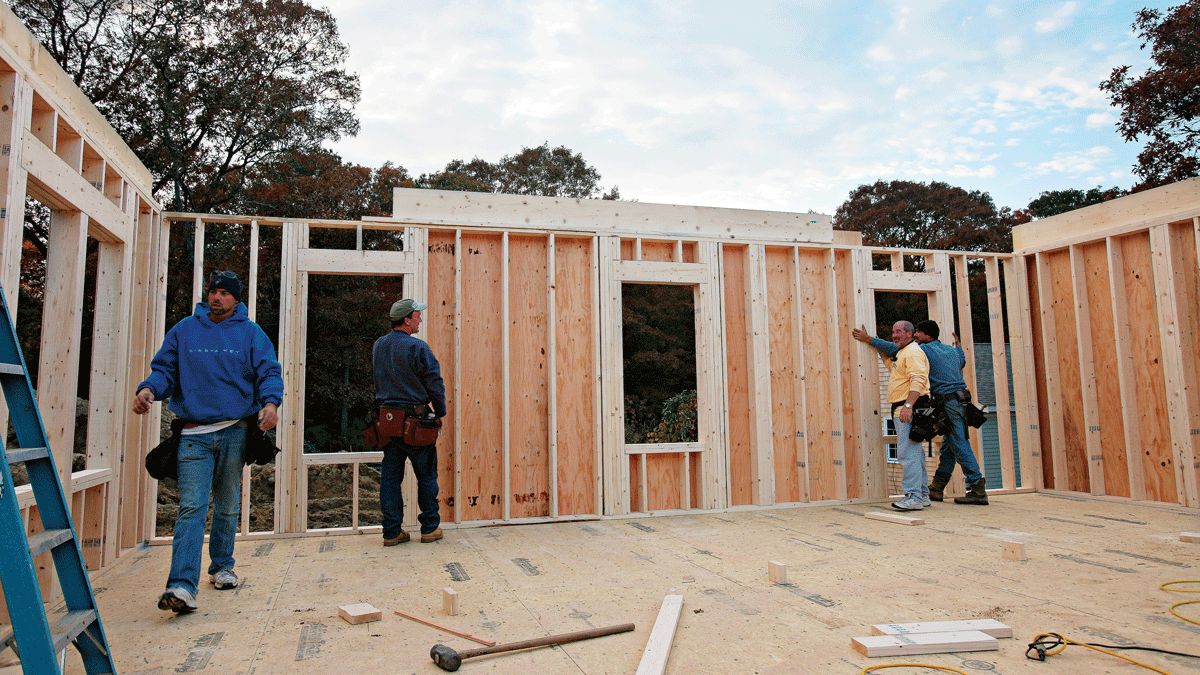

Exterior walls

Exterior walls are framed with 2× material covered with sheathing and siding on the surface exposed to the weather. These walls are usually insulated.

Interior (partition) walls

Interior walls subdivide the inside space of the house, separating rooms and creating closets. These walls are not usually insulated.

Wall plates

Wall plates are the horizontal members at the top and bottom of each wall; they tie the ends of the studs together. The bottom plate is nailed through the floor sheathing and into the joists below. The top plate supports floor joists or ceiling joists. It is common practice to double the top plate in order to tie adjacent walls to each other and provide extra support for second-story floor joists.

Studs

The 2×4 or 2×6 vertical members of both exterior and interior walls are known as studs. They extend between the top and the bottom wall plates. Unlike other framing members, studs can be precut at the mill to one of several standard lengths and are generally installed without further cutting.

Corner assembly

A corner assembly consists of two or three studs nailed together in an L shape to form a rigid corner where framed walls meet. The assembly also provides a stiff, solid nailing surface for attaching interior wall finishes.

Partition backer

A partition backer is an assembly of three studs nailed together into a U shape. When built into a wall, the backer creates a stiff column to which an intersecting wall can be attached. The legs of the U stiffen the backer stud and provide a nailing surface for interior wall finishes.

Framed opening

Openings in walls that accommodate windows or doors consist of several pieces of framing. The full-length studs on the sides of every opening in the wall are called king studs. The somewhat shorter studs that support the ends of a header are called trimmer studs or jack studs. They are nailed to king studs or to other jack studs. A header supports framing above and distributes loads to the jack studs on each side of the opening. The header fits on top of the jacks and between the king studs. A stool (also called a sill or saddle) is a horizontal member at the bottom of a window opening that fits between the jacks. Short framing members that fit under the stool or above the header are called cripple studs. Local building codes may require extra framing members around openings to stiffen them against high winds, as shown in the left photo below.

Wall sheathing

The layer of plywood or OSB that skins the exterior of the wall is called wall sheathing. It adds lateral strength to the wall system by tying the framing members together. It also serves as a nailing base for siding.

Ceiling joists

Ceiling joists are similar to floor joists, except that they do not support conditioned living space above. Their primary purpose is to provide a nailing surface for ceiling materials such as drywall. Because they don’t carry floor loads, ceiling joists do not need to be as wide as the floor joists, although they usually are. Ceiling joists can go between the rafters, or finish the top of a platform with rim joists around the perimeter.

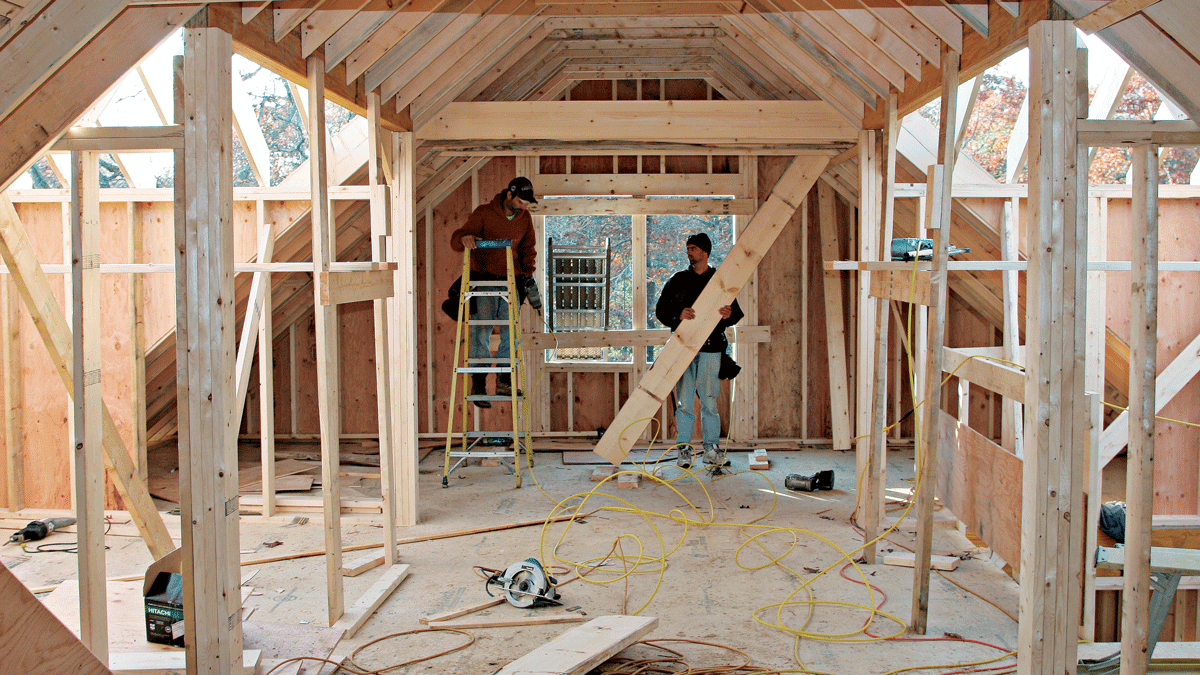

Rafters and Ridge

Angled framing members that create the shape of the roof are called rafters. They support the weight of the roof sheathing and the roofing material and channel the loads to the exterior walls. The board that joins the ends of the rafters at the peak is called the ridge. It is often made of 2× lumber but can be made of other materials. A structural ridge is supported by posts and helps carry the weight of the roof. A nonstructural ridge does not carry roof weight. Both types of ridges provide a bearing surface for the ends of the rafters and tie them together. Rafters also provide a nailing surface for the roof sheathing.

Roof sheathing

The plywood or OSB skin that covers the rafters and joins them together is known as the roof sheathing.

Collar ties

Collar ties are horizontal members that join opposing rafters together. They stiffen the roof and can serve as ceiling joists when the attic is used as living space.

The Building Code: Framing Ground RulesTo protect the inhabitants of our houses as well as the people who build them, houses are built according to a set of rules called building codes. These codes spell out the minimum requirements for most aspects of building a house. Code stipulates the size and grades of the lumber and fasteners that go into the frame as well as how the frame should be assembled to handle all the forces that affect it. Building according to code is your assurance that the house will be strong and safe. Building codes once varied considerably from region to region, but efforts to standardize building practices have led to the development of the International Residential Code (IRC), which was first published in 2000. The IRC is a model code, a template that states can adopt in whole or in part. But even if a state adopts the IRC, local jurisdictions generally amend it to fit their specific conditions (see “Codes for Special Locations” on the facing page). A town in a particularly hazardous fire zone, for example, might decide to make local codes more stringent than the IRC regarding acceptable roofing products. The IRC has now been wholly or partially adopted at the state or local level by all 50 states and the District of Columbia, but you must always follow the specific regulations in your area. Always make sure that your plans reflect any local requirements that may differ from the general building code. Be sure to check with your local building department for information. If your local code differs from anything shown in this book, build according to your area’s requirements. |

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Portable Wall Jack

Short Blade Chisel

Protective Eyewear

View Comments

Don't understand why the sill plate (that sits on the foundation wall) is called a 'mudsill' - there's no mud at all!

Mortar used to be and still is called mud. The sill plate used to be placed into a layer of 'mud' to achieve a level plane. Now it is placed on a layer of sealing material and additional runs or beads of caulking materials in order to hopefully get a good air seal and moisture seal. If we could achieve a good moisture seal we could do away with treated wood. Personally, I don't know why no one has come up with a recycled plastic mud plate or sill plate. Once sealed to the foundation it wouldn't rot and no moisture would be transferred to the wood. As it is the treated wood will still allow moisture to wick into the wood above. Treated wood isn't water proof.