Frame Engineering

Understanding the forces at work in a house frame is a prerequisite for framing the building.

You can spend years in school to become a structural engineer, but you don’t need that kind of training to build a house. Still, a general working knowledge of the forces at work in a house frame and on a frame can be very helpful. Awareness of those forces and how the frame resists them informs your choice of techniques and makes strict adherence to the building code more natural and intuitive, especially in jurisdictions where enforcement of regulations might be more relaxed.

Loads and SpanThe way a frame reacts to the various forces applied to it depends a lot on factors such as how heavily it is loaded and the distance the horizontal framing elements must span. A load is the weight carried by the framing members. Loads are separated into two categories: dead loads and live loads. Dead loads are the fixed weight of the structure, including the materials and any fixtures or equipment that are a permanent part of the building. Live loads, on the other hand, consist of any changeable weight that the structure is subjected to, such as people and furniture. Both types of loads must be taken into consideration when determining the proper size and spacing of framing members. The distance that a framing member can extend between supports is called the span. The distance a particular piece of lumber can span is affected by various factors, including the magnitude and location of the loads it must bear. It is also affected by the species of wood. A 2×6 made of oak can span a greater distance than one made of pine because the material itself is stronger. Span tables are available both online and at most municipal building offices. Although the tables apply to general floor framing, in some areas of the country, plans must be reviewed by an engineer. |

Forces at Work in a Frame

A house looks as though it were simply resting peacefully as it sits on its lot. But beneath the clapboards and shingles, the frame is hard at work resisting forces. Most of these forces have to do with gravity, and the frame must be engineered in such a way that it handles them easily and efficiently. It also has to be ready for forces that come along only once in a while, such as heavy wind or seismic activity.

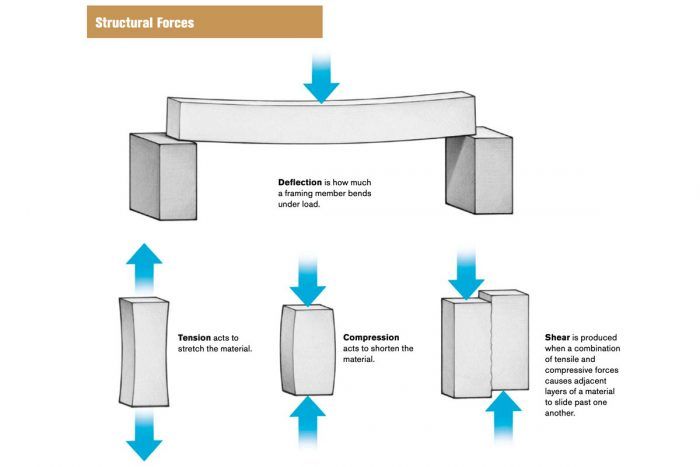

Deflection Deflection is the amount a framing member or a framing system, such as a floor or roof, moves downward when weight is added. Deflection is affected by the spacing of the lumber. For example, standard framing members spaced 16 in. on center (o.c.) might deflect less than wider framing members spaced at 24 in. o.c. Excessive deflection can result in cracked drywall or a cracked tile floor.

Tension and compression The two forces of tension and compression are the opposite of each other. Tension is a pulling or stretching force, whereas compression is a pushing or squeezing force. For example, in a roof with a nonstructural ridge, the weight of the rafters on the plates acts to spread the walls apart. However, the joists below each rafter keep that from happening by pulling the walls together. The joists are then said to be in tension. At the same time, the weight of the floor system pushing down on the studs tends to squeeze them, putting them in compression.

Shear Shear is a force applied perpendicular or opposite to the normal resistance strength of a structure or material. That force could be wind pushing on the side of a building, but it could also be a lean-to roof pushing against studs in a wall. Another example of shear is the downward force on the end of a cantilevered joist. Shear forces can be some of the most subtle yet most destructive forces.

Structural Support

A house frame transfers the weight of a house to the foundation. Starting at the roof, the loads follow lines of support through the rafters, joists, and wall studs. Loads are transferred efficiently when the framing elements line up with each other. But a house is not a sealed box, and those lines of support are often interrupted by openings for doors and windows. The frame must transfer the loads around those holes. If the framing is not uniform, the loads will be distributed in unpredictable ways, which could cause the structure to fail.

Nailing Schedules

Contrary to what the name implies, a nailing schedule has nothing to do with when you drive nails. Instead it has to do with how many nails and what size nails you must use for a given application. Building codes include general nailing schedules for most framing connections. But if you’re building in an area with special code requirements, such as for high winds, a nailing schedule should be included as part of the house plans. The minimum requirements of a nailing schedule must always be followed exactly to ensure the strength of the connections. These details are especially important in certain applications, such as nailing sheathing to the wall framing (see chapter 4). The size and spacing of the nails must be followed precisely or the house will not meet local code requirements. Building inspectors will flag this error in a heartbeat.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Extendable Plate to Plate Level

Bluetooth Earmuffs

Magoog Tall Stair Gauges