The Evolution of Top-Plate Building Codes

Could a single top plate do the job, allowing for reduced thermal bridging and an increased R-value? Learn about top-plate building codes.

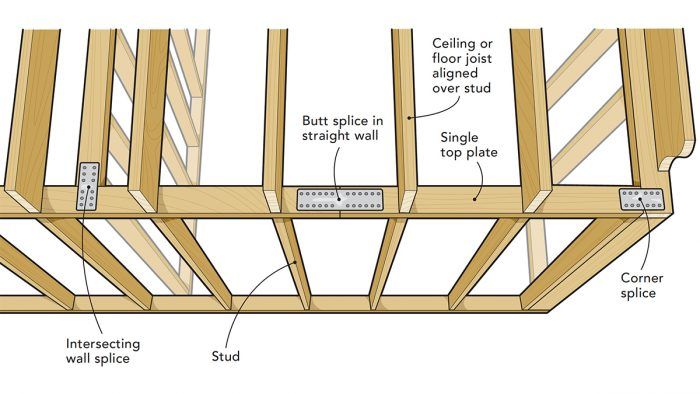

If you’ve ever framed a house using conventional wood-frame construction, you know that the concept of the double top plate just makes sense. The bottom plate and first top plate hold the studs to form the basic wall frame. The double top plate laps at corners and intersections, tying the walls together and plumbing and straightening them up.

In the last century or so, we have come to better understand and quantify the forces of nature we expect new homes to endure. We have also slowly sought validation through science and engineering of the conventional methods we have been using. With this scrutiny, we understand the job the top plates have been doing for us and ways they can be modified while still performing as required.

In the early 1930s, model building codes were developed with conventional wood-frame construction techniques included, and with each new edition, more validation was included for conventional framing methods. Plumbing had always been run through wall cavities, and drilling or notching wall plates to run pipes or ducts had long been common practice. Though there were only a handful of pages of wood-framing code at that time, they included the requirement to strap across the side of the notched top plate, which is still required in exterior walls and interior load-bearing walls. By the 1980s the strap was only required when the notch was more than 50% of the plate width, and in the late ’90s an exception was added that the strap was not required on a side completely covered in wood structural panels. These allowances are still in the latest (2021) International Residential Code (IRC), including Figure R602.6.1 depicting the strap.

The purpose of this strap is to restore the continuity of the top plate and maintain the structural integrity of the wall as a whole. One major role of top plates is to collect lateral wind and seismic loads from the roof or floor above them and transfer those loads to the wall bracing. This load collection puts the plates under tension or compression. The strap helps reestablish the top plate’s ability to handle tension, but interestingly, the ability of a notched top plate to resist compression, which a strap won’t remedy, has not yet been explored or validated in the code. The strap is required when more than 50% is notched, but there is no mention of how deep the notch can be. The entire top plate could be severed—the IRC doesn’t prohibit it—and only strapping or wood-structural-panel sheathing is required. This won’t be changed or addressed in the code until a human is motivated to address it, and no reason has surfaced yet.

In the 1970s, a new concern arose. The energy crisis led to research and development of methods for increasing the energy efficiency of new U.S. homes. These efforts surrounded the creation of the Model Energy Code, but in the early ’80s, this motivation began to affect the building envelope as a whole and how it could support better energy efficiency. Like all framing in a conventional exterior wall, the double top plate is a thermal bridge from the interior drywall to the exterior sheathing. The question arose: Could a single top plate do the job, allowing for reduced thermal bridging and an increased R-value for walls?

An affirmative answer led to a new exception allowing single top plates. To establish continuity at the corners and intersections— previously achieved with the overlapping double top plate—a requirement for a 3-in. by 6-in. steel plate was included as part of the exception. Take note that a “plate” is required, not a strap. This is not the time to look at Figure R602.6.1, previously mentioned, though this is a very common error in code interpretation. This plate goes on the wide face of the wood top plate, either above or below; it is not intended for installation on the side. (The plate is 3 in. wide, but the side of the top plate is only 1-1/2 in.) Unfortunately, because a picture says a thousand words, the figure of the strapping for a notched double top plate is mistakenly applied to this exception for a single top plate. In handbooks from the 1980s for the Uniform Building Code, and still today in the IRC Commentary, you can find the supportive information and an illustration of the intended installation of this steel plate on the wide face of the plate. (Note, though, that the illustration in the Commentary also contains an error: For the condition shown, the plate should be longer and have more nails, according to Table 602.3.2).

As provisions for wood-frame construction—specifically those for bracing—were fine-tuned over the last decade of IRC editions, changes to top-plate nailing provisions led to more-specific provisions for the single-top-plate joints. Section R602.3.2 now directs you to Table R602.3.2 for two different nailing and plate-size requirements, dependent on the seismic design category of the building’s location and the spacing between the structure’s braced wall lines. Generally, buildings with braced wall lines more closely spaced and/or with lower seismic concerns require smaller steel plates to keep the wood top plates together, whether these joints are in straight walls, at corners, or at intersections with interior walls. Buildings with greater spacing between braced wall lines and higher seismic design requirements require larger steel plates with more nails to hold the single wood top plates together. For example, all homes in seismic design categories A through C, and those in the D categories (D1, D2, and D3) with braced wall lines spaced less than 25 ft. apart, require a 3-in. by 12-in. plate with 12 nails on each side of the joint to tie together butt joints in the top plates of straight walls. D-category homes with braced wall lines spaced 25 ft. or greater apart require a 3-in. by 16-in. plate with 18 nails on each side for these same joints.

Another energy conservation method that rose in popularity in the ’80s is framing with studs 24 in. on center. This spacing reduces thermal bridging by replacing some wood with insulation, but it also increases the span of the top plates between bearing locations (studs). Yes, double top plates act like small beams spanning between studs. Provisions, now found in Section R602.3.3, were added to address the loads from joists, trusses, and rafters that may land within this increased span between studs. When joists, trusses, or rafters are spaced 16 in. or less, their individual concentrated loads are small enough that they can land anywhere on the double plates.

However, if the spacing is greater than 16 in., such as a 19.2-in. or 24-in. layout, each member carries more load and thus places a greater concentrated load on the top plates. In these cases, the joists, trusses, or rafters typically must bear within 5 in. of a stud, but there are exceptions. If the double plates are 2×6 or 3×4, if a third 2×4 plate is installed, or if blocking is installed below the double 2×4 plates between the two studs (to stiffen the spanning plates to a three-ply member), the joists, trusses, or rafters are again allowed to land anywhere on the top plates.

When using the exception for a single top plate, however, there’s no recognition of the plate as a beam, and rafters, trusses, and joists of any spacing must land within 1 in. of a stud, center to center. This results in a minimum of 1/2 in. of a 2x rafter or joist being over a stud.

Though these provisions have been developed over about a century, there is still a very large omission not addressed in the IRC. As mentioned above, when notching a double top plate for plumbing or HVAC ducts, only strapping on the side (edge) of the double top plate is required to reestablish tension, but the plates could be severed completely. This would not leave them functioning as a very effective beam spanning between studs.

Code aside, when following the load path of a rafter bearing in the center of a double top plate that is severed in the span, especially if the studs are 24 in. on center, the path is disconnected. A double top plate is not designed or meant to cantilever beyond a stud to carry an additional load. The code won’t tell you this directly; you have to go beyond the words, understand the intent, and make the wise decision to add a stud under that rafter. I’d recommend no more than a 1-in. offset, as required for a single plate.

Glenn Mathewson is a consultant and educator with BuildingCodeCollege.com.

From Fine Homebuilding #306

RELATED STORIES

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Tajima Chalk Rite Chalk Line

Musings of an Energy Nerd: Toward an Energy-Efficient Home