Combining Sheathing With a WRB and Air Barrier

Building-science expert Peter Yost takes an in-depth look at two sheathing systems that integrate a structural panel with bulk water and air management.

Image Credits: Image #1: Zip sheathing - Elden Lindamood; ForceField sheathing: Georgia-Pacific

Full Disclosure: First, there are a lot of different ways to get continuous air and water control layers on the exterior of a building enclosure. You can use housewrap, taped-and-sealed rigid foam insulation, liquid-applied membrane, or either the Huber Zip or Georgia-Pacific ForceField system. Each approach has strengths and weaknesses.

All things considered, I prefer the performance delivered by Zip System sheathing and tape. But when I learned about ForceField, I decided to dig into how these two systems compare.

Second, I have done quite a bit of work with Huber Engineered Woods, the manufacturer of Zip sheathing, because of the company’s support for the Wingnut Test Facility and a new Hanley-Wood educational series on high-performance building (Home Building Crossroads). Their support to my work is technical, not financial. I did receive test sample materials from both Georgia-Pacific and Huber for this blog.

What do you call these two systems?

It can be difficult to even just name these product systems. Huber states that “Zip System sheathing and tape is an innovative structural roof and wall system with an integrated water and air barrier.”

Georgia-Pacific states, “The ForceField air and water barrier system from Georgia-Pacific consists of structural engineered wood sheathing panels laminated with a proprietary air and water barrier.”

So, these systems combine structural sheathing with a water-resistive barrier (WRB) and an air barrier.

Third-party assessments

The primary third-party reference for the technical properties and performance of the Zip system is ICC-ES Report ESR-1474 (re-issued 10/2016).

For ForceField, the primary third-party reference is APA Product Report PR-N136 (revised December 14, 2016).

How are the two systems similar?

The common elements of Zip and ForceField are:

How are the two systems different?

- (1) Lamination of WRB facer – Zip’s proprietary overlay is an integral part of the OSB manufacturing process; that means that the overlay (or membrane) is fused during the compression formation of the bed of strands and resins into OSB panels. The ForceField System proprietary overlay is glue-laminated to the OSB panels after the fact.

- (2) The OSB face used for the WRB differs – Zip System panels uses the “rough” side of their OSB for the WRB overlay; ForceField System uses the “smooth” side of their OSB for the WRB overlay.

- (3) Roof sheathing – All Zip System panels are approved as a structural sheathing panel and underlayment for roofs; ForceField System panels are not.

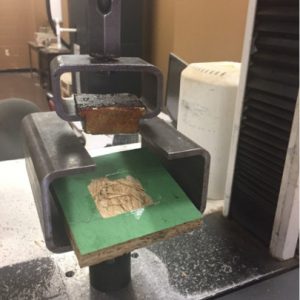

- (4) Compliance with key ICC Acceptance Criteria (AC) – Zip System panels full comply with AC310 — Acceptance Criteria for Water-Resistive Membranes Factory-Bonded to Wood-Based Structural Sheathing, Used as Water-Resistive Barriers. Zip tape fully complies with AC148 — Acceptance Criteria for Flexible Flashing Materials. On the other hand, ForceField System panels and tape are not documented as compliant with these key standards. (Note: In images #2 through #4, below, samples of Zip System panel are subjected to an “Overlay Bond Durability Test,” a test modified from AC310. It’s frankly remarkable that after boiling and drying and subjected to pull-apart stress, the failure is not at the bond between the WRB overlay and the OSB; it fails largely by separating strands from the surface of the OSB. It’s not possible to conduct this test on ForceField System sheathing; the WRB facer or overlay delaminates completely from the OSB during the boiling phase of the test.)

The tapes also differ:

- (1) Zip System tape is much thicker than ForceField tape (Zip – 0.012 inch; ForceField – 0.003 inch) and has a polyolefin backer. The ForceField tape backer is described as a polymeric film.

- (2) Zip System tape comes 90 feet to a roll; ForceField System tape comes 180 feet in a roll. ForceField System tape can be hand-torn to length; Zip System tape must be cut to length.

- (3) When installed, Zip System tape must be rolled as stipulated in the manufacturer’s directions and not loaded for a minimum of one hour, while the ForceField System tape can be applied with just hand pressure and achieves its full adhesion nearly immediately.

- (4) ForceField system tape is approved by the manufacturer for installation down to 0°F; Zip System tape is currently manufacturer-approved down to 20°F.

Finally, the warranties differ:

- (1) The ForceField warranty is described as “Lifetime Limited” to the original owner, and is non-transferable. The Zip system warranty is described as “30-year System Limited” to the original owner.

- (2) The Zip System warranty covers all system components: OSB panels, Zip overlay, Zip tape, and Zip liquid flash; ForceField limits their warranty to just their OSB panels.

- (3) Coverage – ForceField’s warranty states, “In the event of Product Delamination… GP will… either repair or replace the nonconforming portion of the Product, or reimburse you twice the original retail purchase price.” The Zip System warranty states, “…the system …will satisfy the Air and Water Resistance Properties Test…” and “[the warranty] is limited to the repair or replacement, at HEW’s option, of materials giving rise to the failure to comply with this warranty.”

Wingnut testing of the two systems

Many of you may know about my frustration with laboratory standardized testing under conditions that are fundamentally different from what happens on job sites. (Please see Two Wingnuts Describe Their Backyard Tape Tests or the BuildingGreen blog content, Sticky Business, for more information on the work of the Wingnut Test Facility).

The following information is strictly anecdotal, and represents my own attempt to stress each system, with an admittedly woeful sample size of one sample per test.

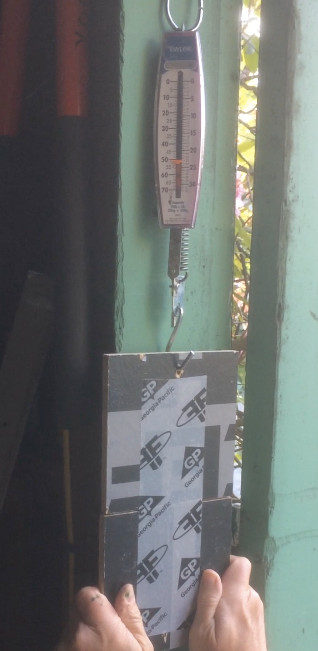

Straight-Pull Test (see Images #5 and #6, below).

I followed the manufacturer’s installation instructions for each system and used a “fish scale” to measure how much force the system withstood. You can see that both systems have very strong bonds between the facer and the PSA tape, withstanding up to 50 pounds of force in this test. Note that the Zip System tape stretches with the force while the ForceField System tape has little to no give.

Perpendicular-Load Test Split Substrates Including Window Flange (see Images #7 through #12, below).

This test was developed to better represent the forces that tapes and substrates could experience at a window installation, where one-half of the tape adheres to the wall sheathing and one-half adheres to the window flange. (We used both PVC and aluminum flanges.) A 3/8-inch slot in the panel represents the gap between the round opening and the window unit.

For all the details of this test, see the “Wingnut Test Facility – WTF Field- and Benchtop-Testing of Building Materials & Systems, BuildingGreen, Inc. September 16, 2015.”

When I set up this test in my garage recently, I followed the protocol and had the tests underway at around noon on Thursday (June 15, 2017), doing the initial wetting with a spray bottle. I applied 10 squirts (about 6 milliliters) to the front and back of each panel. (When spraying the back side where water could “pool,” I inverted the panel to “drain” any standing water out of the slot).

When I returned to the garage at 5:30 p.m., both ForceField setups had failed, while both Zip System sheathing and tape setups were still holding. As you can see from the photos, on the setup with aluminum flange, the tape let go at the flange, while on the setup with the PVC flange, the tape let go of the ForceField panel.

In the past, when testing multiple tapes, this test has gone on for weeks and then months, with some systems failing in the first day. In particular, the Zip System sheathing and tape setups persisted for more than a year of outdoor temperature and relative humidity swings and repeated wetting on both surfaces. And while other PSA tapes worked better on either the PVC flange or the aluminum flange, Zip System tape held just fine with both PVC and aluminum window flanges.

Wetting, then perpendicular pull, test (Images #13 through #15).

In this test, I drilled a round hole in one square, taped that square to another square, and then wetted the hanging results about 10 times, spraying water over the top edge of the top square, on the face of both squares and tape, and around the round hole. I did this to simulate the exposure to rain that could happen if the panels were up on a building but not yet taped or sealed around penetrations.

When I did the perpendicular pull test, the average force to separate the tape from the panel was 5 pounds for the ForceField System sheathing and tape and 20 pounds for the Zip System sheathing and tape. You can see in the last photo that the surface of the ForceField has become “rougher” with the repeated wetting, and some of the ForceField System facer has pulled off, while the Zip System square shows no signs of any facer delamination.

I did not observe any deterioration. Nor did I test around the holes I drilled. (Essentially, I ran out of time on this test.)

Summing up

Any system relying on PSA tape for both watertightness and airtightness is breaking the first law of building science: physics trumps chemistry. Having said that, it is almost impossible to achieve high-performance levels of airtightness without sticky chemistry. So if you are going to break that first law by having the leading top edge of the tape not protected by a lap, you had better have a lot of faith in the bond between the tape and all its substrates.

The second law of building science is to shelter or protect your air and water management systems. But how do you shelter them without burying them where they are difficult or impossible to inspect, repair, or replace?

I include this context to emphasize just how important are the bonds between substrates and tapes, both for the Zip System and the ForceField System. They have to maintain their bonds for the life of the assembly, because inspection and repair or replacement means taking the assembly apart.

The bonds between the Zip System facer and OSB, between the Zip System tape and the Zip facer, and the the bond between the Zip tape and key assembly materials such as PVC and aluminum window flanges, are all more robust than those of the ForceField system. This is supported by both standardized test results and Wingnut Test Facility benchtop testing.

Some might argue that these bonds represent overkill in the Zip System; perhaps the ForceField System bonds are perfectly sound and represent an improvement over other approaches to air and water barrier systems. For my money, thought, the consequences of being wrong on this are too critical to go with a reduced safety margin.

A final note: For the best bond, PSA tape should be applied on dry, clean substrates under mild temperature conditions. But perhaps the most important condition is pressure. It’s pressure that activates or “wets” the adhesive and allows it to flow so that it achieves maximum surface area contact with the substrate. You can’t press a tape too much, but you can press it too little!

Originally published on GreenBuildingAdvisor.com.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Utility Knife

Respirator Mask

Loctite Foamboard Adhesive